Symmetrical permanent-magnet linear synchronous motor

A permanent magnet synchronous linear, symmetrical technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of unstable operation, eddy current effect, small suspension height, etc., to simplify the control equipment, improve the utilization rate, Avoid the effect of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

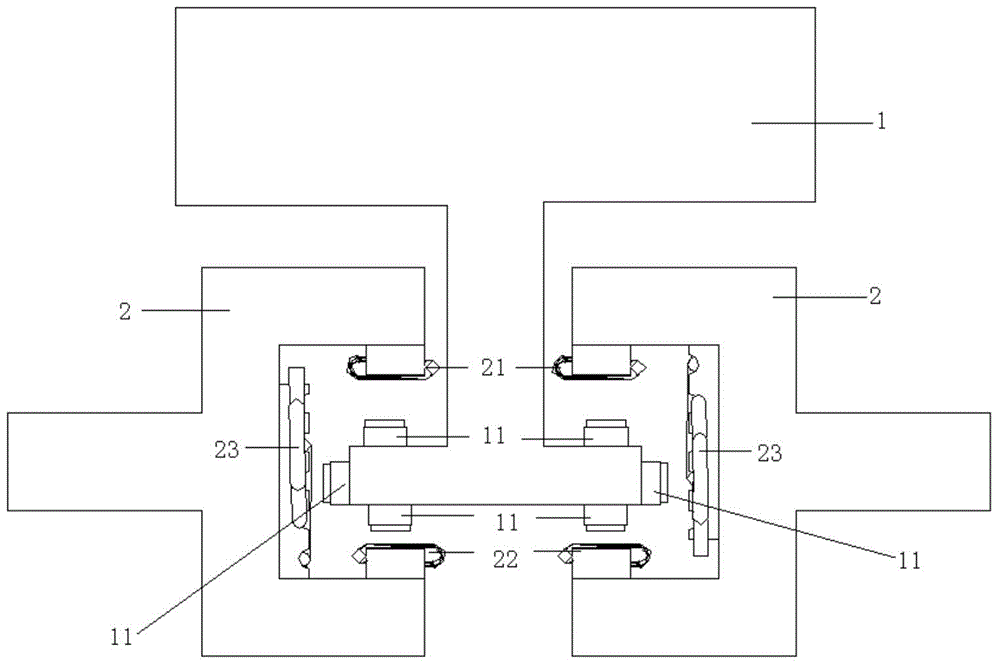

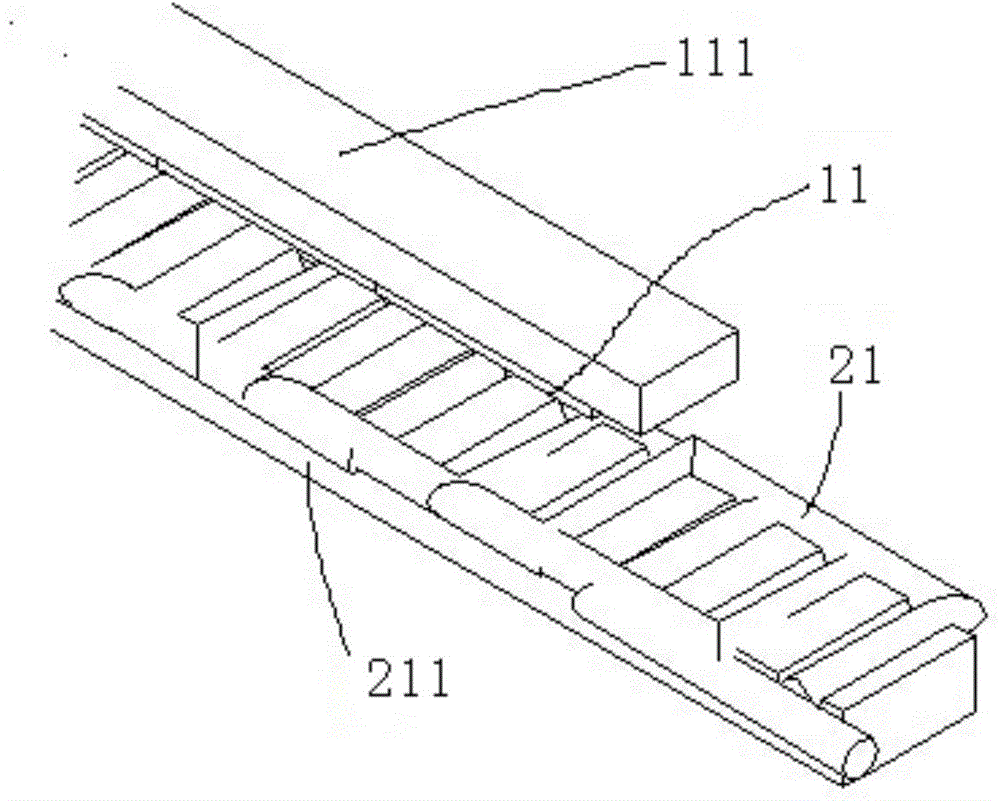

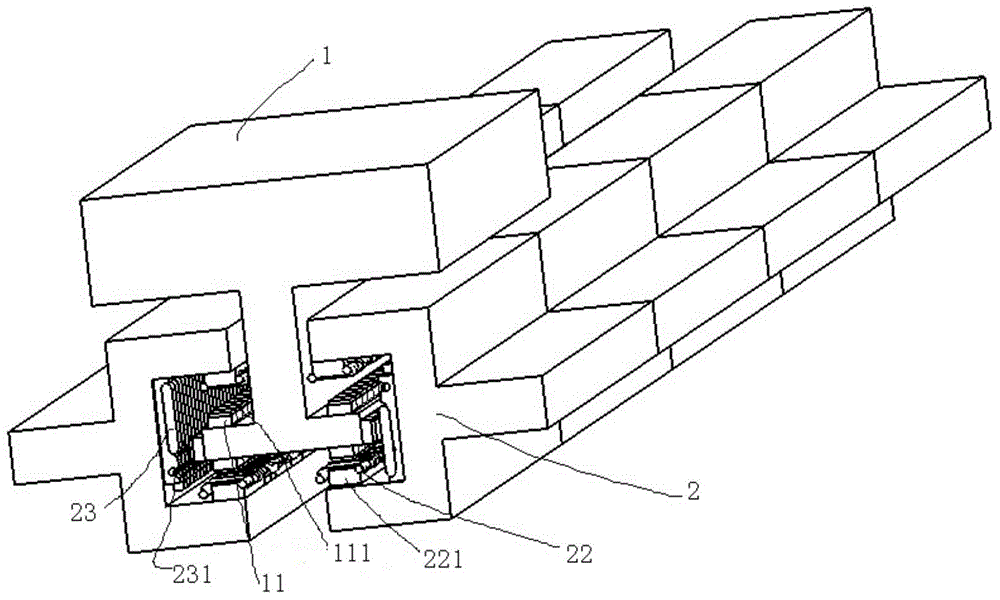

[0025] refer to Figure 1 to Figure 3 , a symmetrical permanent magnet synchronous linear motor, including a mover 1 and a number of stator guide rails 2 symmetrically arranged on both sides of the mover, and a plurality of the stator guide rails 2 constitute the movement track of the mover; the mover 1 Three sets of arrayed permanent magnets 11 are symmetrically arranged on both sides of the bottom, the stator guide rail 2 has a U-shaped structure, and the opening ends of the U-shaped structure of the stator guide rails on both sides are opposite; the opening of the U-shaped structure The upper and lower positions of the end are fixedly installed with traction force coils 21, 22 with the same structure, and the inner side of the bottom of the U-shaped structure is fixedly installed with a levitation force coil 23;

[0026] The levitation force coil 23 located inside the bottom of the U-shaped structure interacts with the arrayed permanent magnet 11 located at the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com