Method for wire-cutting controlling metal wire moving

A technology of metal wire and wire cutting, which is applied in the direction of metal processing equipment, electrode manufacturing, accessory devices, etc., and can solve the problems of unstable tension and acceleration of metal wire a

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

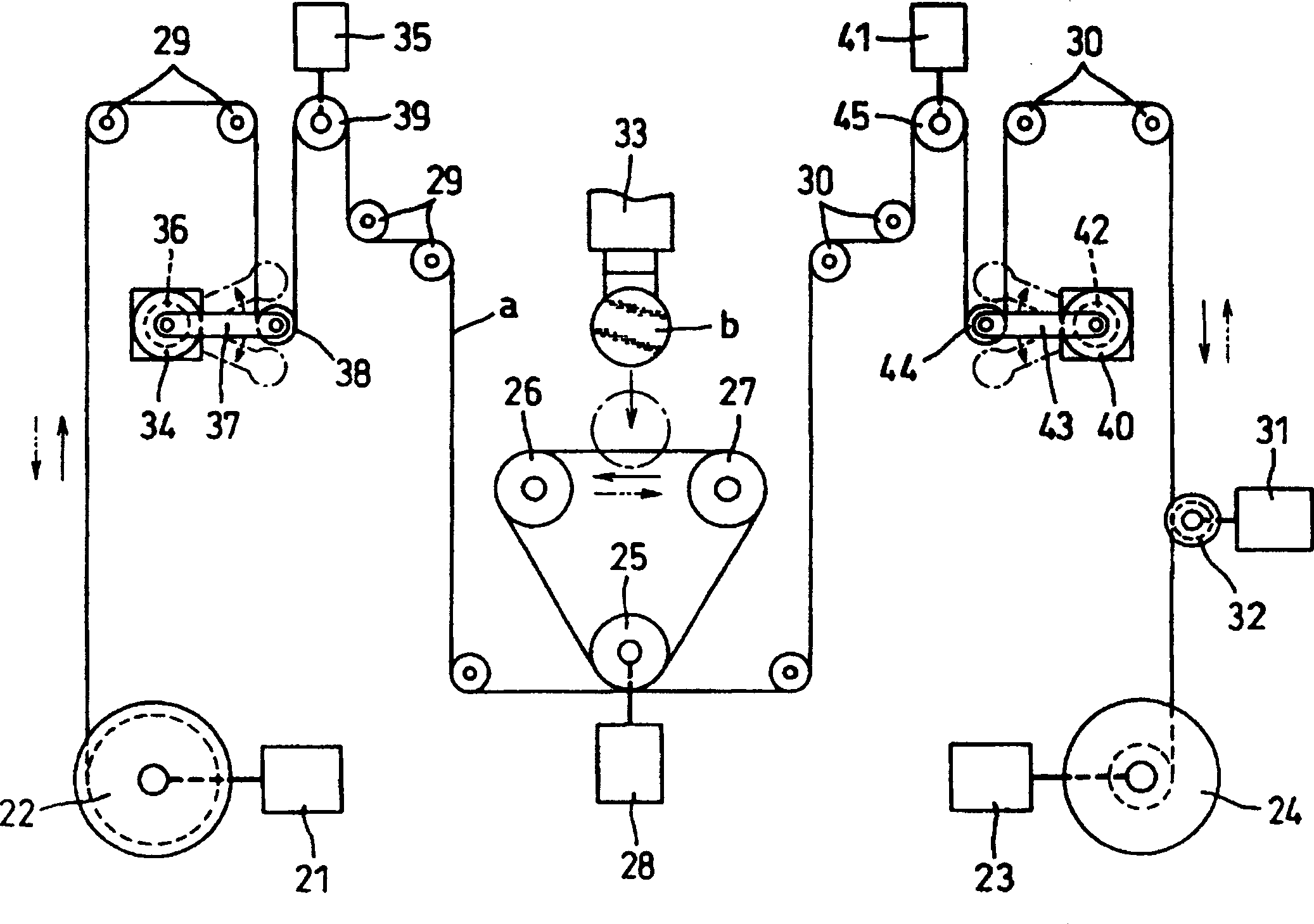

[0030] Embodiments of the present invention combine figure 1 Make an explanation.

[0031] figure 1 It is an embodiment of the wire cutting method using the present invention to control the running of the metal wire. Between the wire feeding reel 22 that feeds and takes up the metal wire a through the forward and reverse rotation of the power motor 21 and the wire take-up reel 24 that also performs the wire take-up and wire feeding through the forward and reverse rotation of the power motor 23 Between, three multi-groove rollers 25, 26, 27 are installed, wherein one multi-groove roller 25 is driven by the power motor 28 to carry out forward and reverse rotation, while the metal wire a drawn from the wire supply wheel 22 passes through a plurality of guide wheels 29, Lead to the multi-groove rollers 25, 26, 27, after the outer circumference of the multi-groove rollers 25, 26, 27 is repeatedly wound side by side, then through a plurality of guide wheels 30 and the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com