Automatic speed-changing wide-swing-angle oil pumping machine

A self-variable, pumping unit technology, applied in mechanical equipment, production fluids, wellbore/well components, etc., can solve the problems of long upstroke time, easy oil leakage, large wear, etc., to improve efficiency and avoid oil leakage effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

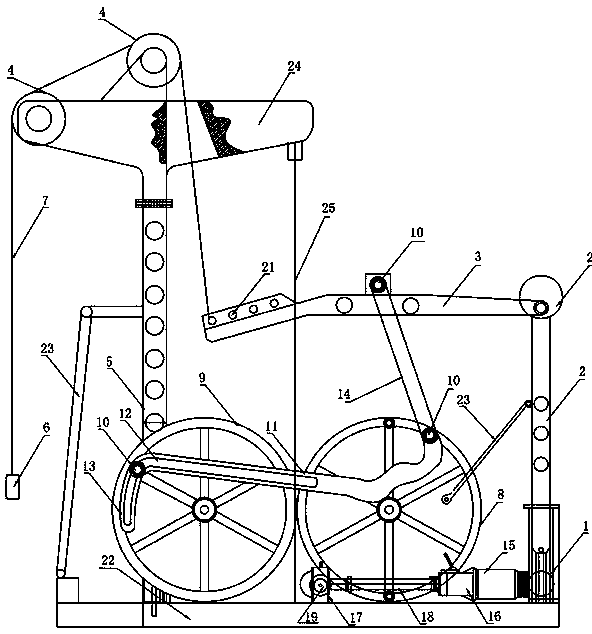

[0034] see figure 1 The self-variable wide swing angle pumping unit includes a motor 1, a speed change mechanism, a rocker arm prop 2, a rocker arm 3 arranged on the rocker arm prop 2, a bracket 5 provided with a fixed pulley 4, and a wellhead oil pumping device 6. The motor 1 is connected with the speed change mechanism, and the suspension rope 7 provided at the end of the rocking arm 3 is connected to the wellhead oil pumping device 6 through the fixed pulley 4 on the support 5. The well head oil pumping device 6 here can be an oil well pump or other existing oil pumping equipment. The transmission mechanism is connected with a driving crank wheel 8, and the driving crank wheel 8 is meshed with a driven crank wheel 9. The driving crank wheel 8 is connected with a connecting piece 11 through a bearing 10, and one end of the connecting piece 11 is connected with the driven crank wheel 9. The other end of the part 11 is connected with the rocker arm 3 through the connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com