Automatic-rise-fall computer display device bracket

A display stand and automatic lifting technology, which is applied in the direction of machines/stands, instruments, supporting machines, etc., can solve the problem of inability to accurately control the distance of rising and falling, the time of rising, falling and stopping, and the inability to adjust Issues such as speed of ascent and descent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

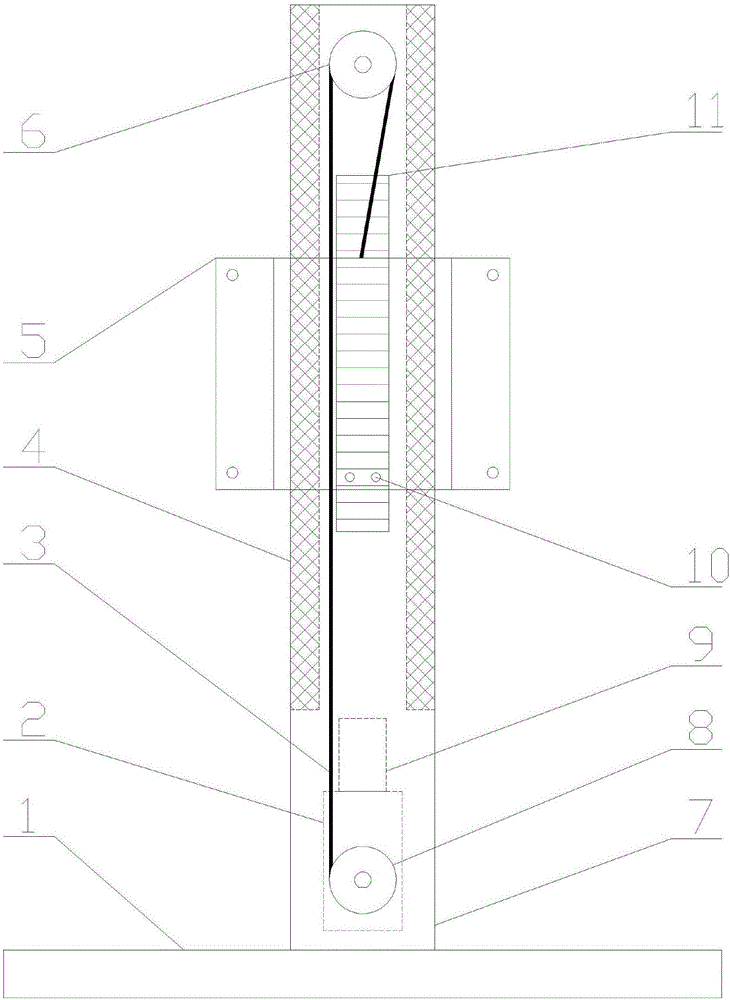

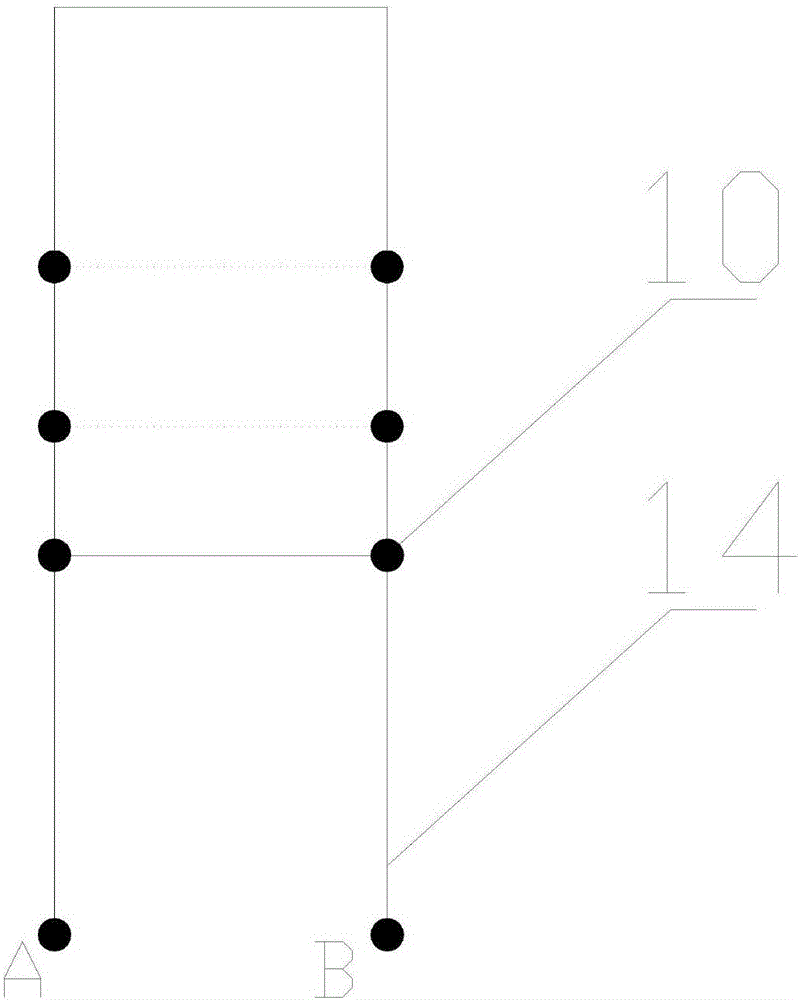

[0045] as attached figure 1 As shown, the automatic lifting computer monitor support of the present invention includes a support part, a lifting device, a control part and a power supply part; the lifting device is arranged in the supporting part, and the control part includes a position detection circuit 11 and a control lifting device lifting The single-chip microcomputer 9; the position detection circuit 11 is connected with the single-chip microcomputer 9; the power supply part is connected with the control part and the lifting device; the position detection circuit 11 includes a U-shaped resistor 14 and two position sensing pins 10, The U-shaped resistor 14 is fixed on the supporting part, the position sensing pin 10 is fixed on the lifting device, and the two position sensing pins 10 are connected and movably connected to both ends of the U-shaped resistor 14 .

[0046] Described lifting device comprises worm gear motor 2, driving wheel 8, stay rope 3, driven wheel 6, sl...

Embodiment 2

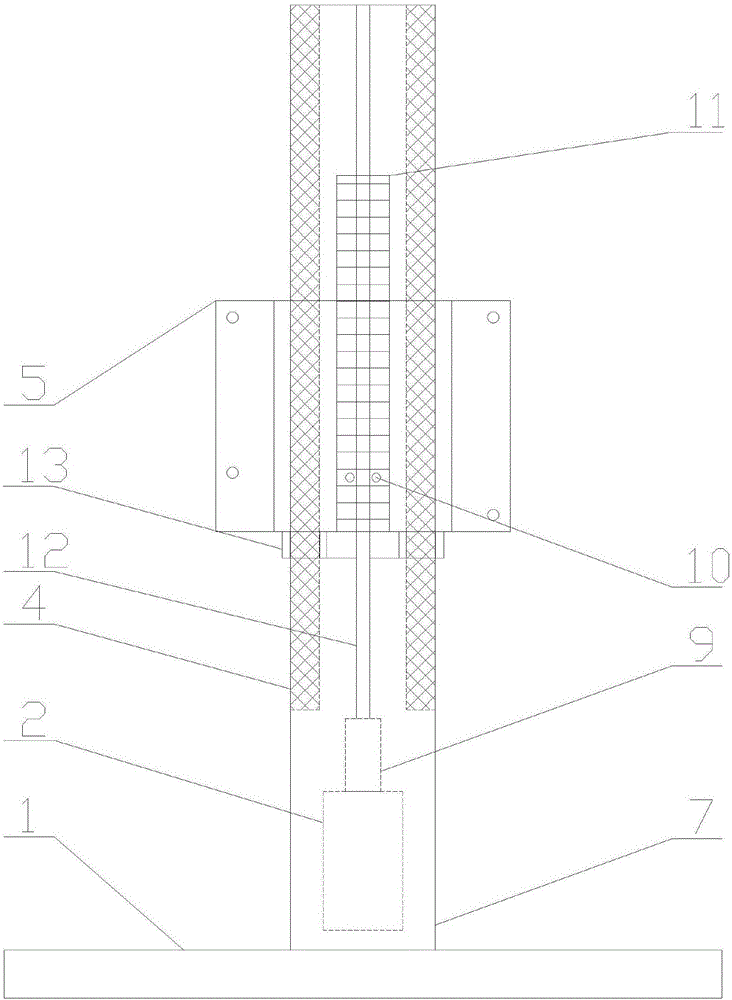

[0065] as attached figure 2 As shown, the lifting device of the present invention is a screw lifting device, and the screw lifting device includes a worm gear motor 2, a threaded screw 12, a guide rail 13 with a threaded hole, a sliding track 4 and a display fixed tackle 5. The screw 12 is fixed on the output rotating shaft of the worm gear motor 2; the screw 12 is matched with the threaded hole of the guide rail 13; the guide rail 13 is movably fixed on the sliding track 4; the display is fixed on the trolley 5 is fixed on the guide rail 13; the single-chip microcomputer 9 is connected to the worm gear motor 2. Only the lifting device of this embodiment is different from that of Embodiment 1, and other structures are the same as those of Embodiment 1 except that.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com