Material discharge mechanism for production of graphene

A discharge mechanism and graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of low efficiency and slow discharge, and achieve the effects of high efficiency, accelerated discharge, and fast discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

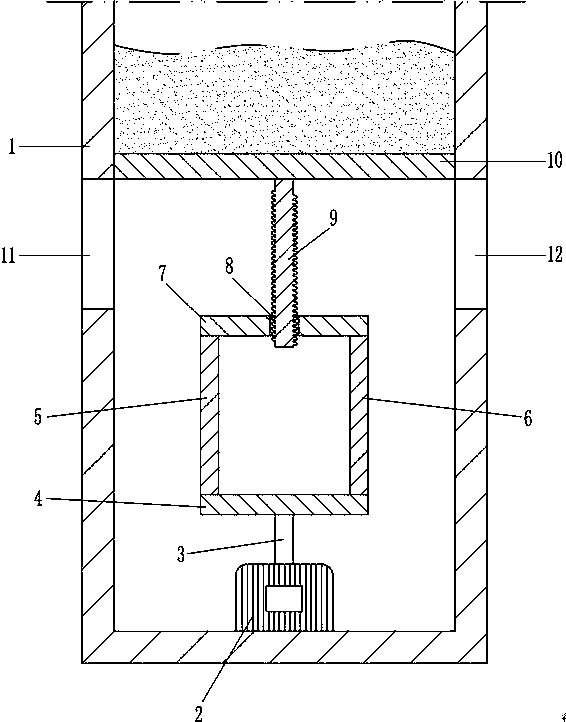

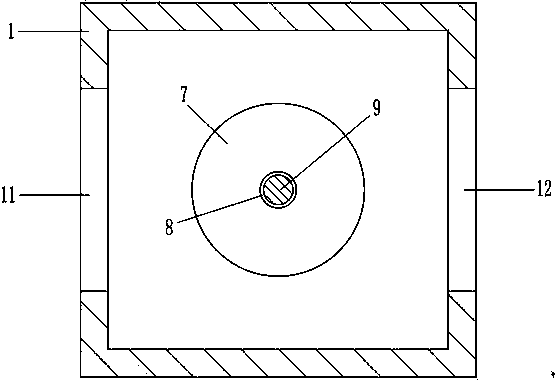

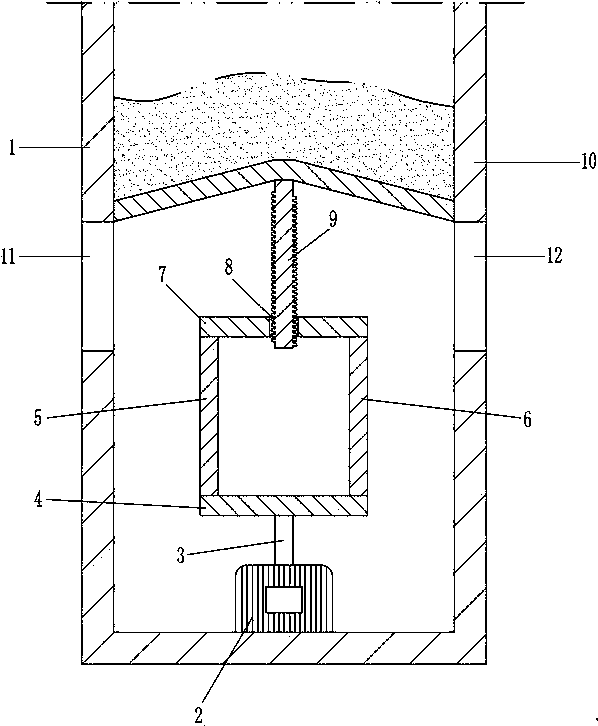

[0035] Referring to accompanying drawing, a kind of discharge mechanism that is used for graphene production, as Figure 1-10 As shown, it includes a reaction vessel body 1, a reciprocating motor 2, a rotating shaft 3, a first rotating plate 4, a first pole 5, a second pole 6, a second rotating plate 7, a screw 9 and a tray 10; the reciprocating motor 2 It is fixed on the inner bottom of the reaction vessel body 1, and the bottom of the rotating shaft 3 is connected to the output end of the reciprocating motor 2; the first rotating plate 4 is a circular rotating plate and is fixed on the top of the rotating shaft 3; The rods 6 are all fixedly connected to the top of the first rotating plate 4 along the vertical direction, and are respectively located at both ends of the same diameter direction of the first rotating plate 4; the second rotating plate 7 is matched with the first rotating plate 4, and fixed connected to the top of the first pole 5 and the second pole 6; There is...

Embodiment 2

[0039] This embodiment is similar to Embodiment 1, and further, the tray 10 is an inverted V shape; the middle of the inverted V-shaped tray 10 is raised, which can accelerate the discharge of graphene and improve work efficiency.

Embodiment 3

[0041] This embodiment is similar to Embodiment 1, and further, the top of the tray 10 has a first groove 13 and a second groove 14; therefore, the graphene falling on the tray 10 gathers in the first groove 13 and the second groove 14, prevent graphene from accumulating around the top of the tray 10, and prevent graphene from wasting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com