Conductive wire batch grabbing device

A technology for grabbing devices and conductive wires, which is applied in the field of batch grabbing devices for conductive wires, and can solve problems such as simple and convenient grabbing devices that do not exist in loop-forming card-issuing lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

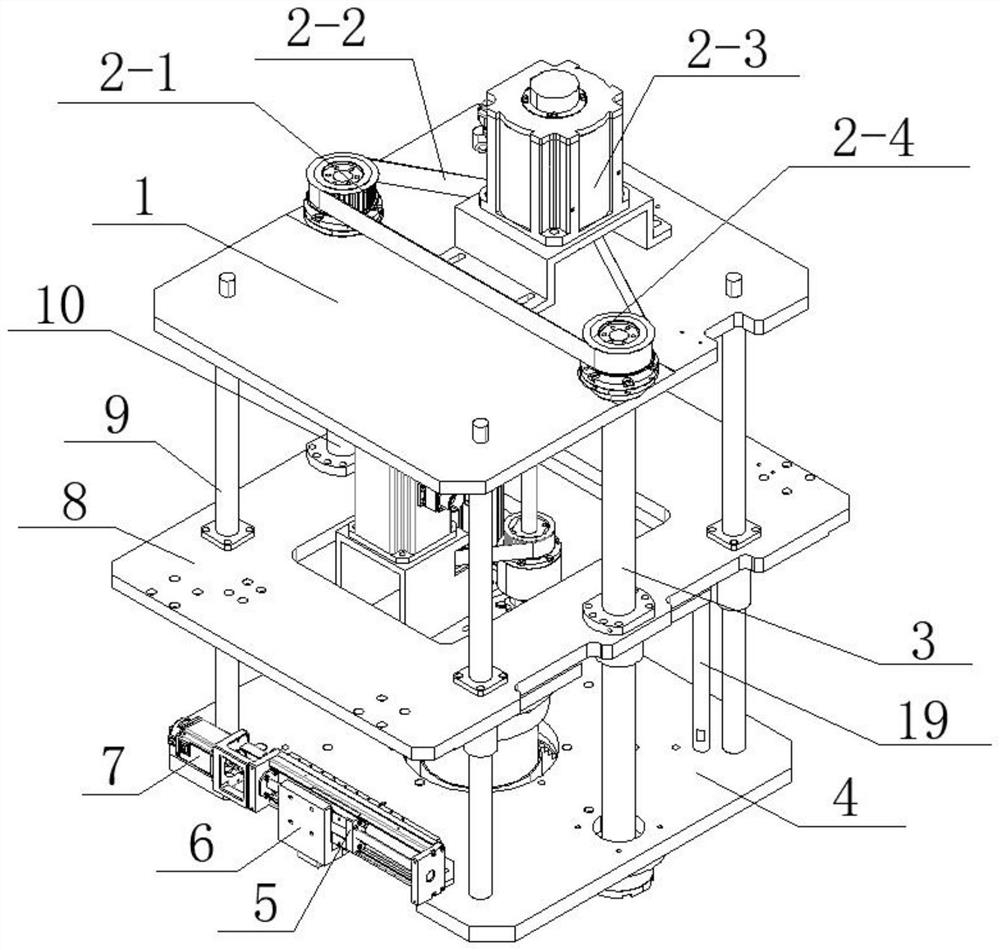

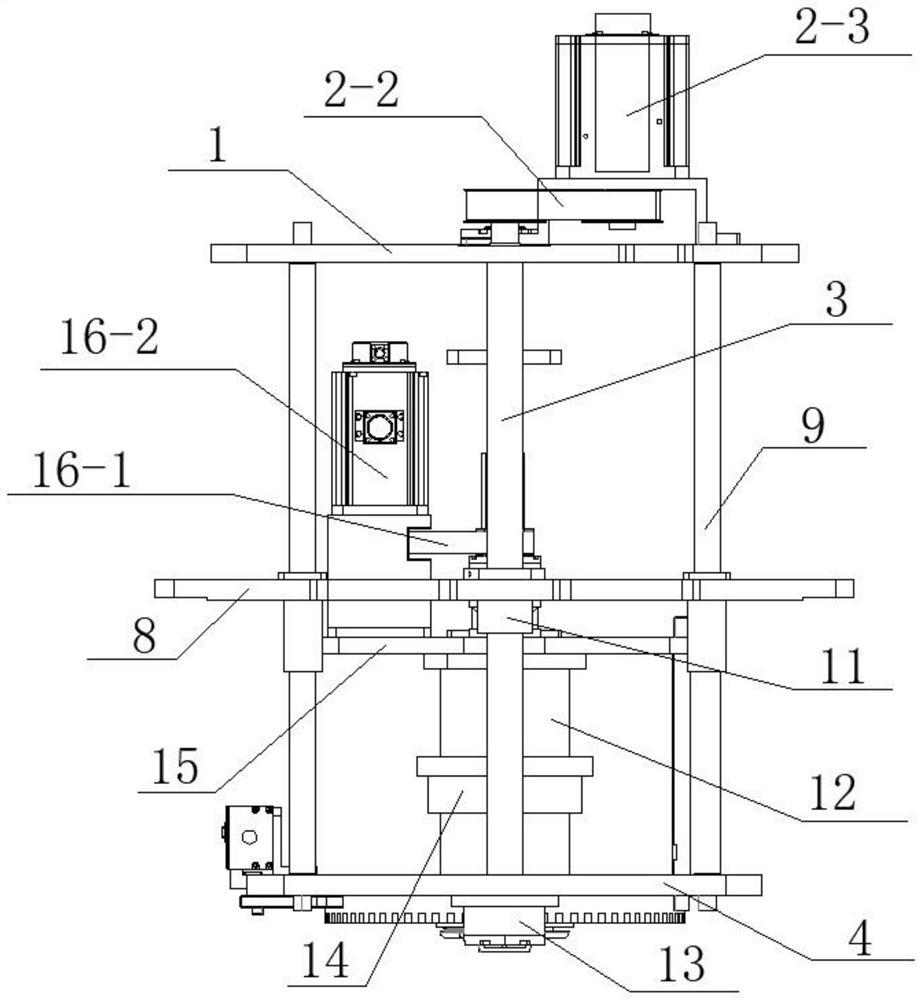

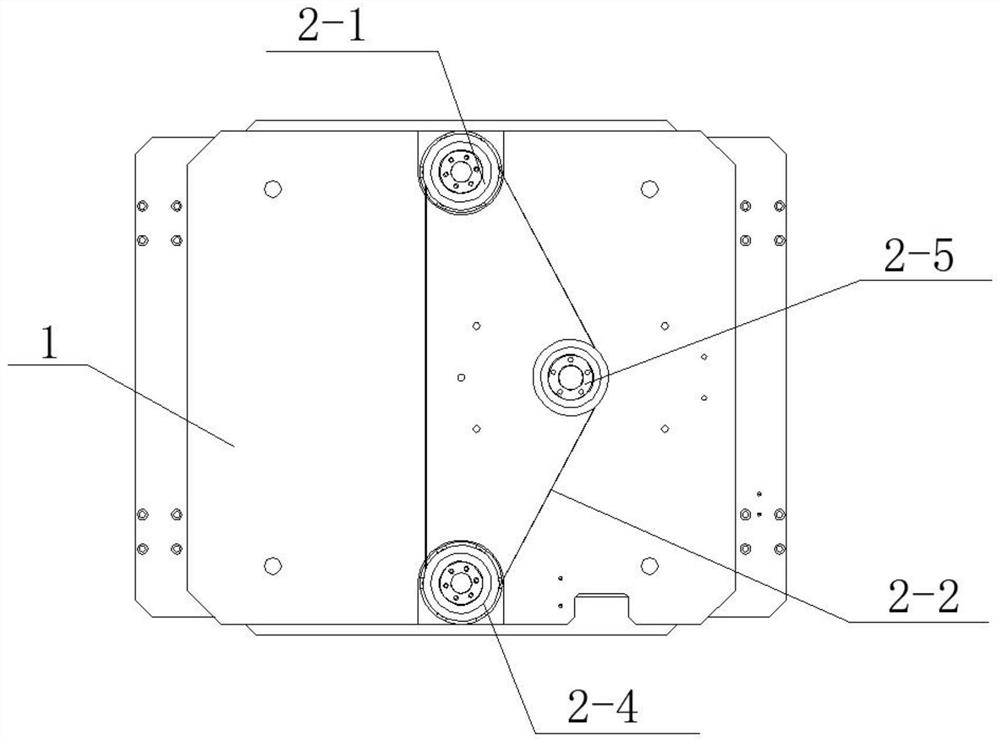

[0042] Example: refer to Figure 1-15 , a batch grabbing device for conductive wires, comprising a lifting mechanism 1 2 installed above the top plate 1, the lifting mechanism 1 2 includes a lifting motor 1 2-3 that controls the rotation of the driving wheel 1 2-5, and is driven by a synchronous belt 1-2- 2 Connect the synchronous wheel 1 2-4 and the synchronous wheel 2 2-1 which rotate with the driving wheel 1 2-5, the synchronous wheel 1 2-4 is fixedly connected with the lead screw 1 3, and the synchronous wheel 2-1 is connected with the lead screw 2 10 Fixed connection. Bearings are fitted inside the synchronizing wheel 1 2-4 and the synchronizing wheel 2 2-1, and the bearings are matched with the outer rings of the lead screw one 3 and the lead screw two 10;

[0043] The moving assembly is controlled by the lifting mechanism one 2 and connects the top plate 1 and the bottom plate 4. The moving assembly includes a nut one 11 connected with the outer ring of the lead screw o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com