Infrared servo bridge type cutter control system

A control system and cutting machine technology, applied in general control system, control/adjustment system, computer control, etc., can solve the problems of easy interference of stone cutting accuracy, cumbersome control process, waste of water resources, etc., and achieve high speed and high control accuracy , the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

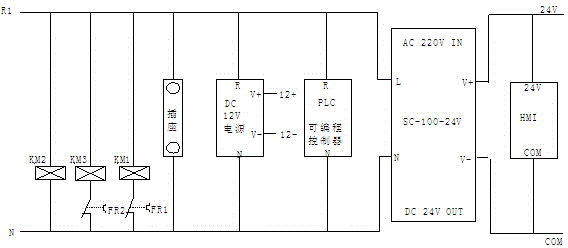

[0029] see figure 1 , which is a structural diagram of the main control circuit of the control system of an infrared servo bridge cutting machine proposed by the present invention.

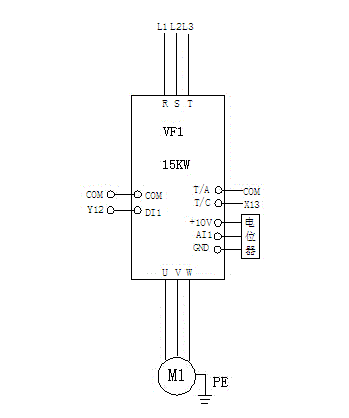

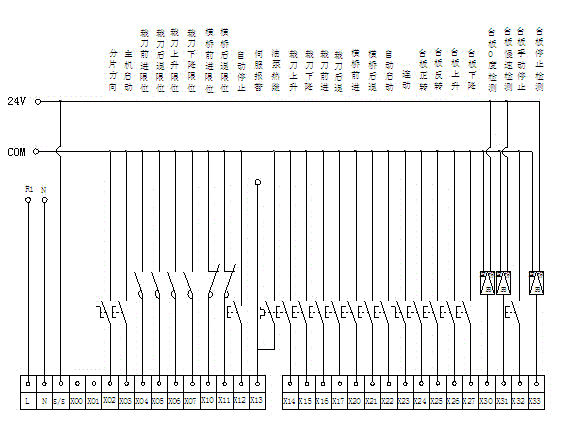

[0030] like figure 1 As shown, an infrared servo bridge cutting machine control system includes: a main control circuit, a power control circuit and a PLC control circuit, the main control circuit is connected to the power control circuit, and the power control circuit is connected to the PLC The control circuit is connected; the main control circuit includes a power supply line, and a total power switch, an ammeter, a voltmeter and a motor drive device arranged on the power supply line; the power supply circuit adopts a three-phase four-wire power supply mode, and the power supply line The main power switch QF1 is set at the input end, and the two ends of the voltmeter are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com