A special crane for the production of aluminum profiles

A technology for cranes and aluminum profiles, applied in the field of special cranes for the production of aluminum profiles, which can solve the problems of motor damage, unreliable lifting, high temperature rise, etc., achieve the effects of reducing starting current, changing lifting speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to facilitate those of ordinary skill in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

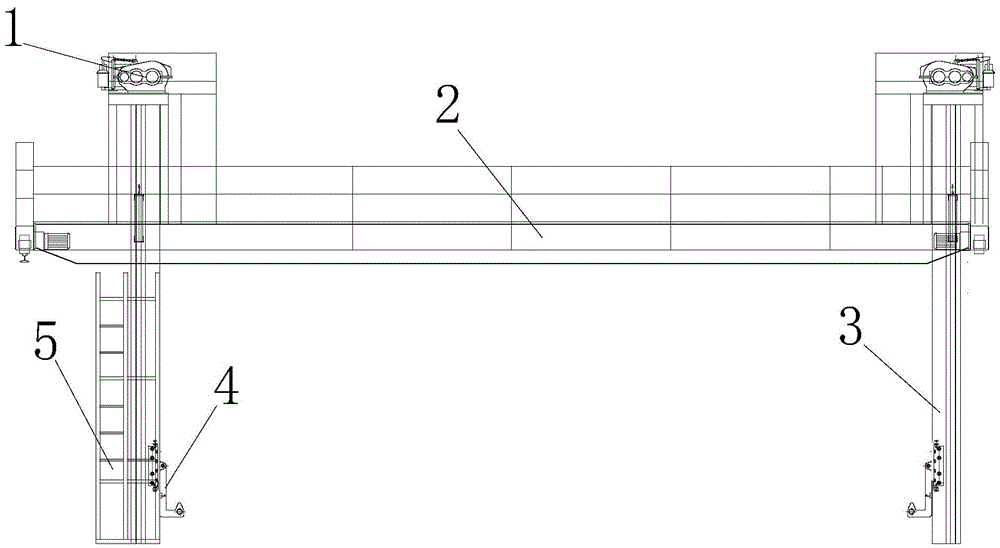

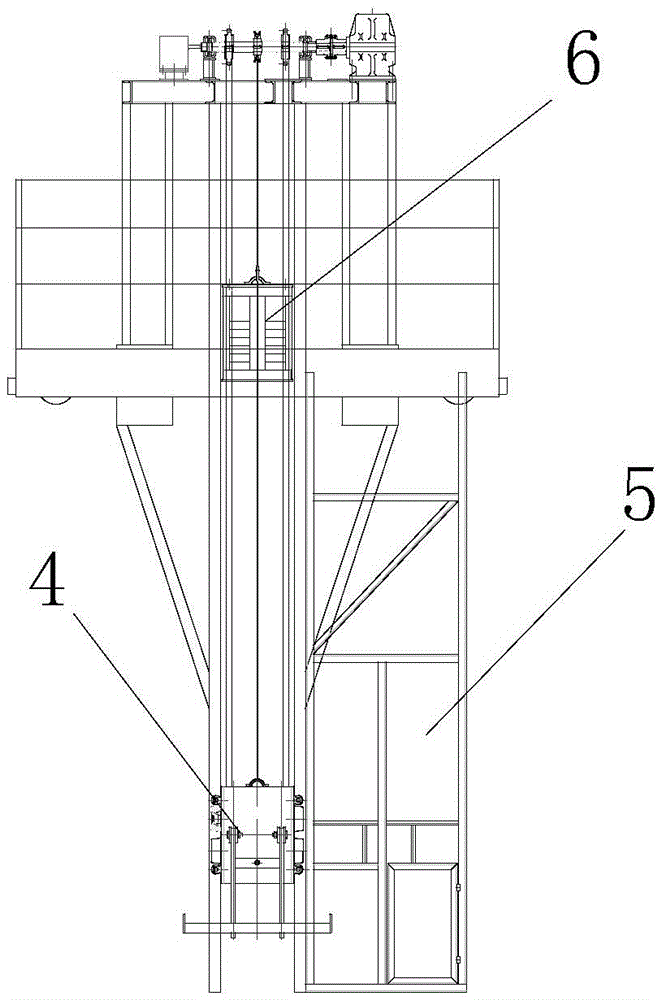

[0037] Such as figure 1 , figure 2 As shown, a special crane for the production of aluminum profiles includes: a lifting main machine 1, a bridge frame 2, a lifting frame 3, a sliding trolley 4, an operating room 5 and a counterweight 6.

[0038] Wherein, two sets of lifting main frame 1, sliding trolley 4, and counterweight 6 are respectively configured for each crane, and lifting main frame 1 is fixed on the main girder 21 of bridge frame 2 through a support.

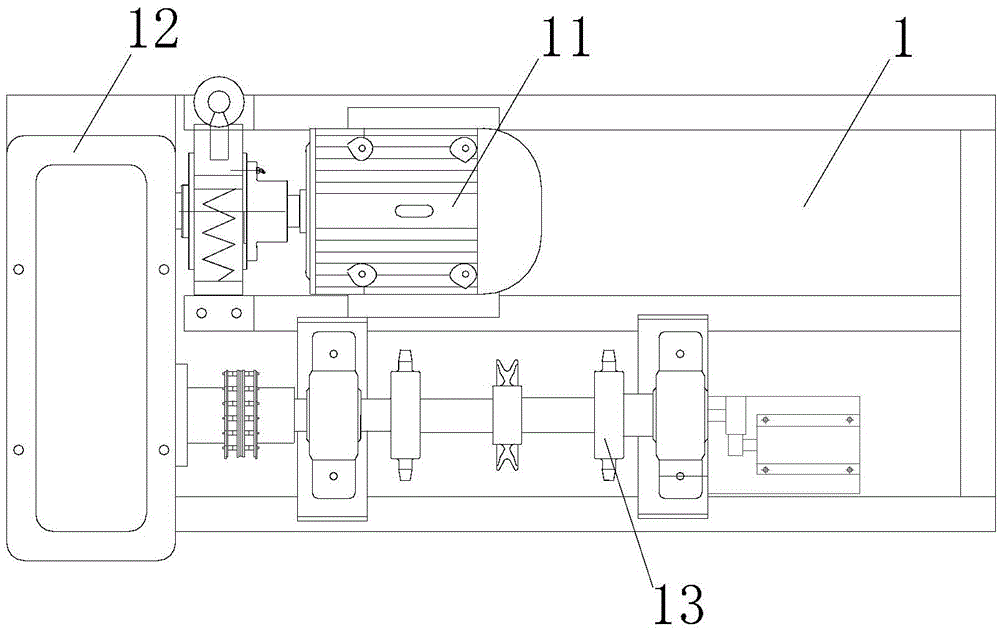

[0039] Such as image 3 As shown, the hoisting main machine 1 is composed of a hoisting base, a motor 11, a speed reducer 12, and a sprocket 13 connected through a mechanical structure. Due to the poor working environment of the hoist, frequent starts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com