Lifter with short mounting distance and large stroke

A technology with installation distance and large stroke, which is applied in the direction of lifting frame and lifting device, can solve the problems of increasing material cost, labor cost, reducing the volume of the lifting device, reducing the stability of the lifting device, and affecting the transmission efficiency, so as to reduce assembly failure and reduce The production cost and the effect of improving the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

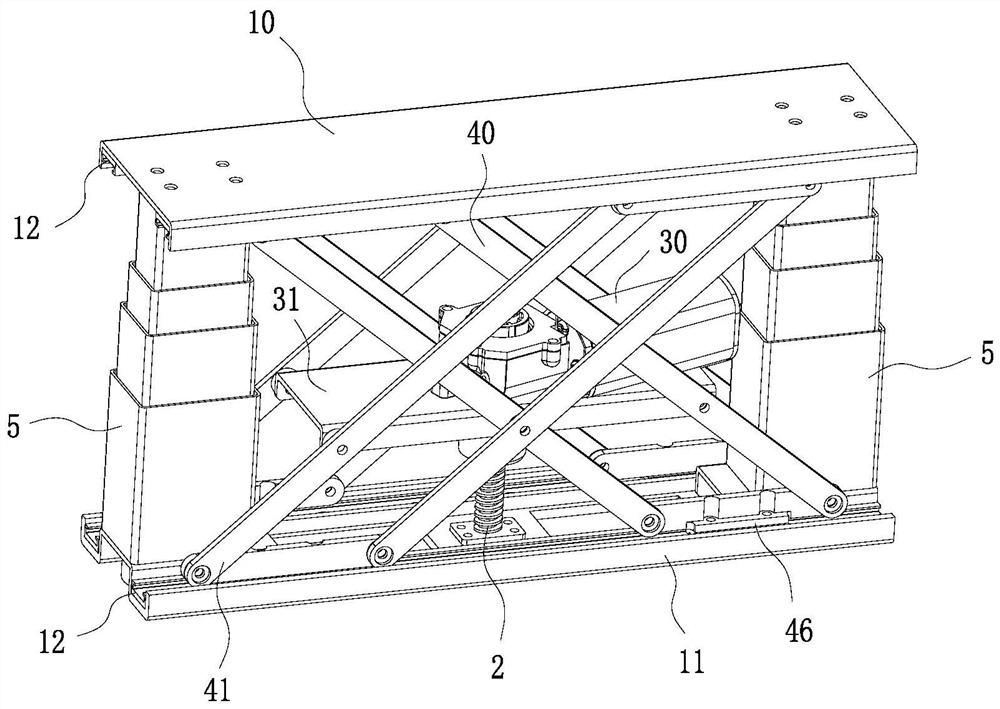

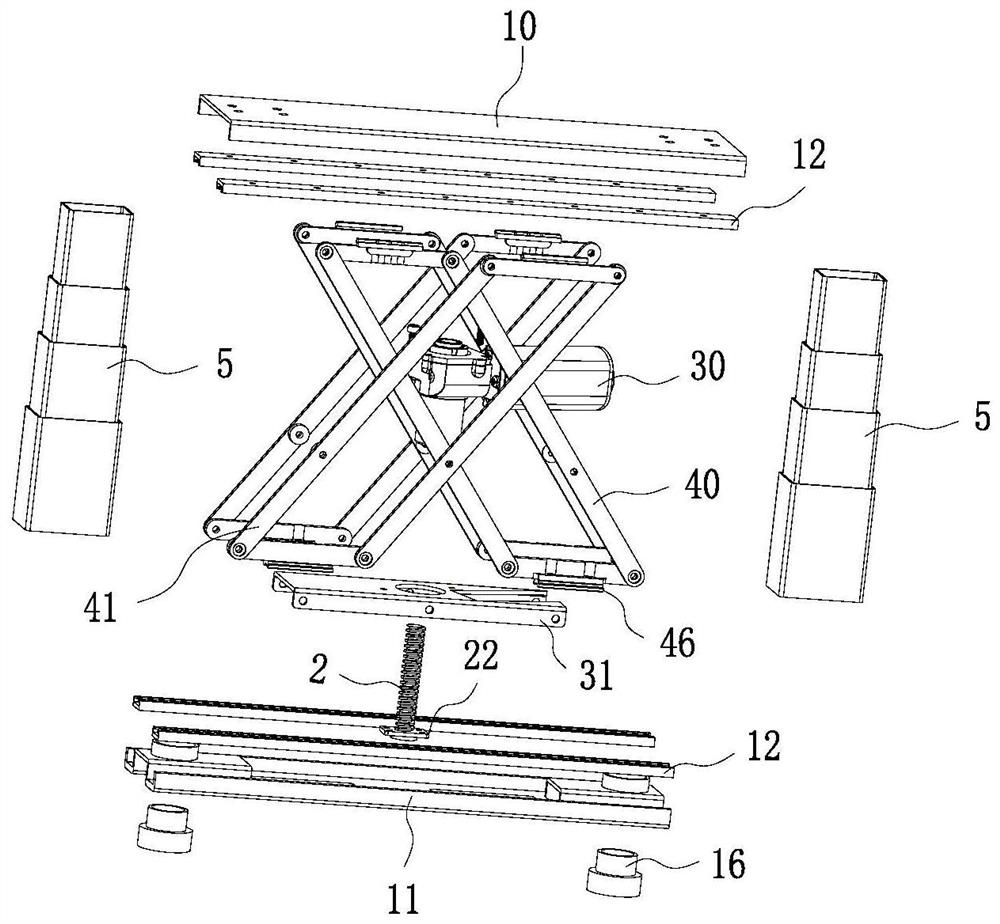

[0033] Such as Figure 1 to Figure 3 As shown, this embodiment shows a lifter with a low installation distance and a large stroke, including a top plate 10, a bottom plate 11 and a drive device for controlling the lifting of the top plate 10. The drive device includes a drive motor 30 and a drive motor 30. The screw mandrel 2 that is driven by the output shaft, the screw mandrel 2 is provided with a screw mandrel nut 21 matching with the thread of the screw mandrel, the drive device is fixed between the top plate 10 and the bottom plate 11, and the drive device is provided with a connection plate 31, a connecting rod set is arranged between the top plate 10 and the bottom plate 11, the two ends of the connecting rod set are respectively slidingly connected with the bottom plate 11 and the top plate 10, and the middle part of the connecting rod set is connected to the side of the connecting plate 31 by rotation. The driving device controls the lifting of the connecting plate 31...

Embodiment 2

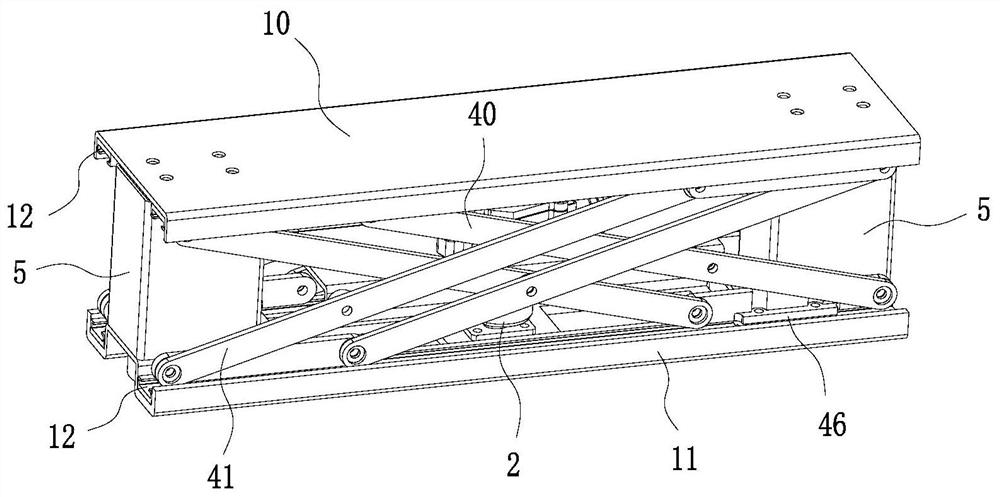

[0048] Such as Figure 4 to Figure 6 As shown, the main difference between this embodiment and Embodiment 1 is that the telescopic column 5 is omitted in this embodiment, and the linkage group includes an upper cross link 43 and a lower cross link 44, and the upper cross link The end of the rod 43 is rotatably connected with the end of the lower cross link 44, and the connection between the upper cross link 43 and the lower cross link 44 is connected with the connecting plate 31 through a rotating shaft, and the connecting plate 31 is provided with a The first chute 32 where the rotating shaft slides horizontally, the other end of the rotating shaft is provided with a first roller 45 that prevents the rotating shaft from detaching from the connecting plate 31, and the upper cross link 43 is hinged with one end of the top plate 10 to form a first hinged end 14, form a sliding connection with the other end of the top plate 10 through the cooperation of the second roller 47 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com