Spinning device for controlling fiber arrangement structure through synchronous rotation and spinning process thereof

A technology of fiber arrangement and synchronous rotation, applied in the field of textile processing, can solve the problems of ineffective reduction of yarn residual torque, deterioration of yarn quality, friction of false twist section, etc. The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the implementation of the present invention will be further described below in conjunction with the accompanying drawings.

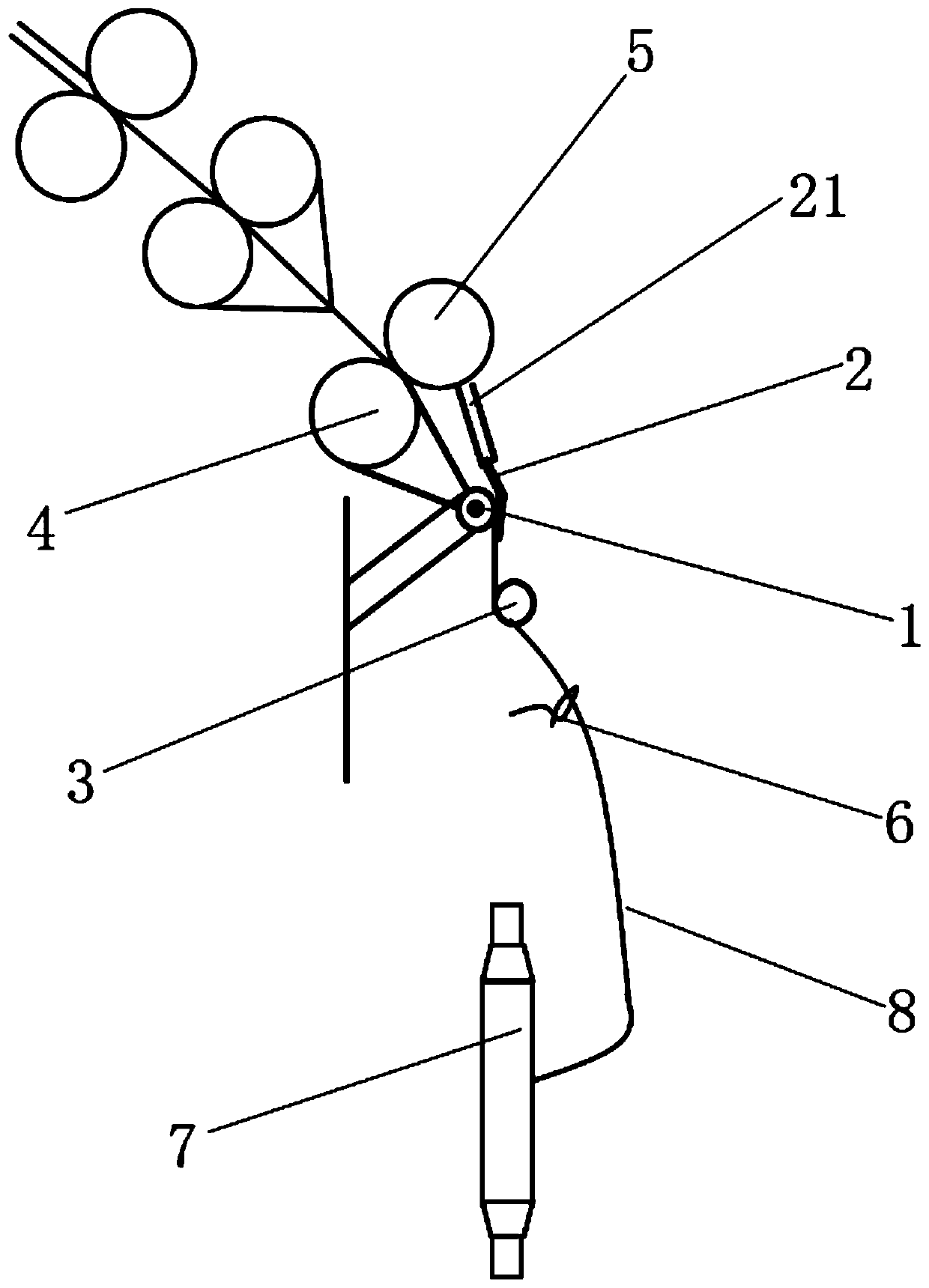

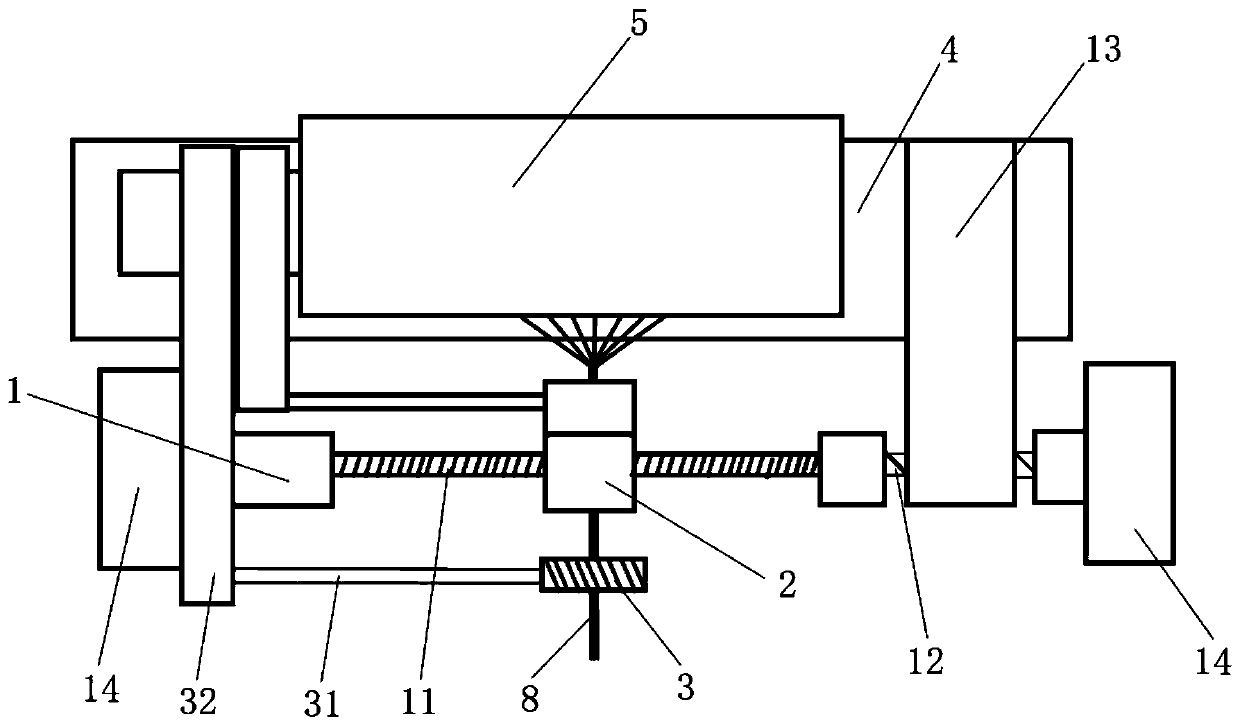

[0028] Please refer to figure 1 and figure 2 , the embodiment of the present invention provides the spinning device that synchronously rotates and controls the fiber arrangement structure, comprising a first rotating shaft 1, a yarn pressing reed 2 and a second rotating shaft 3.

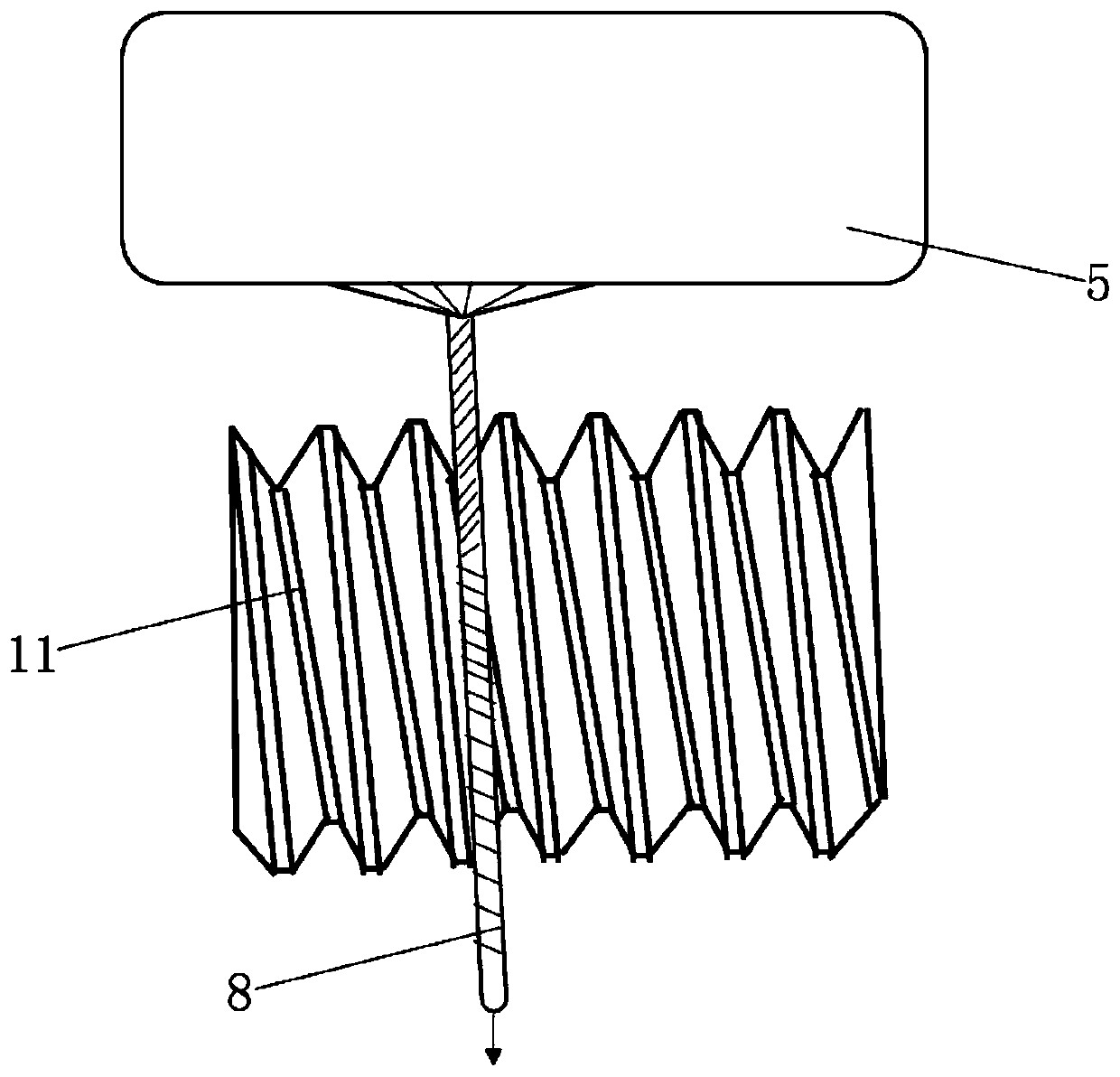

[0029] The two ends of the first rotating shaft 1 are respectively fixed under the front jaw through bearings 14, and the middle part of the first rotating shaft 1 is provided with a threaded fiber finishing section 11 and a belt connecting section 12 at intervals. The fiber finishing section 12 described in this example is The thread size on the section 11 can be selected according to the actual yarn count, the outer diameter of the fiber finishing section 11 is the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com