Roller blind balance regulator and roller blind with same

A regulator and roller blind technology, applied in the direction of balance weight, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of inconvenient production, increased inventory, affecting the use of roller blinds, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

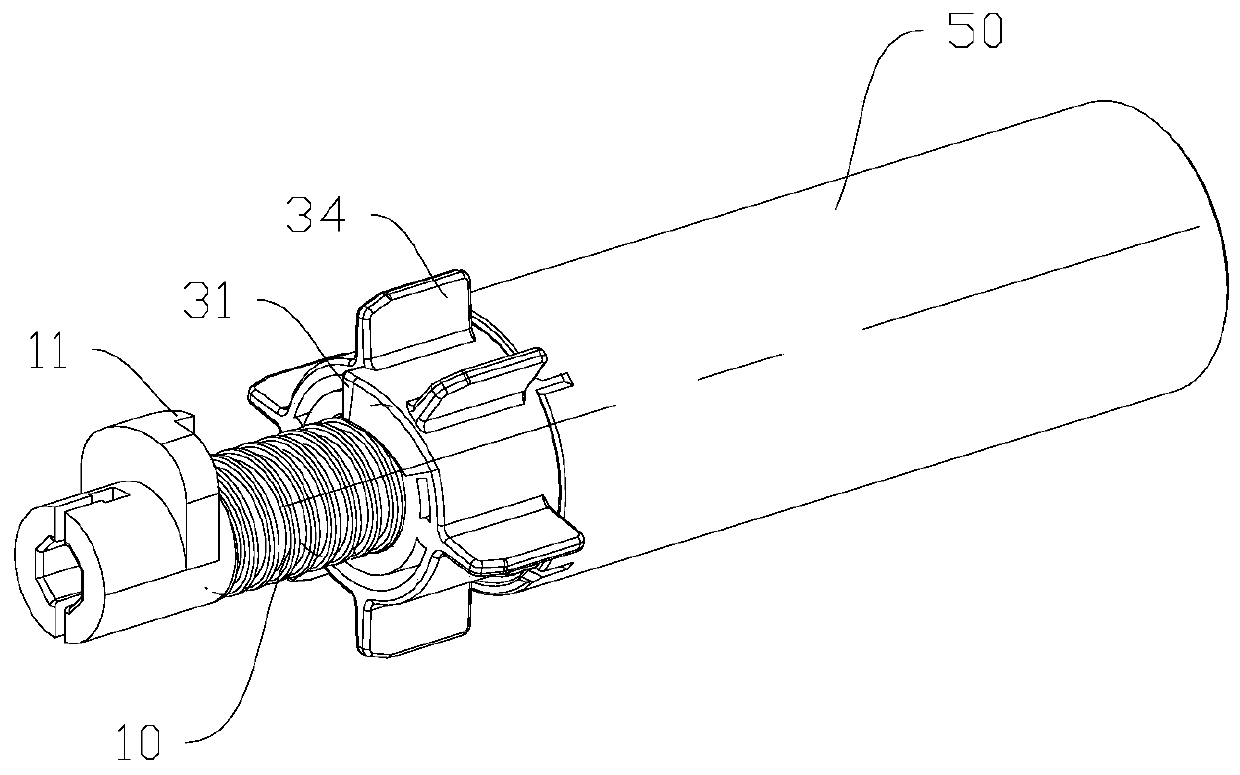

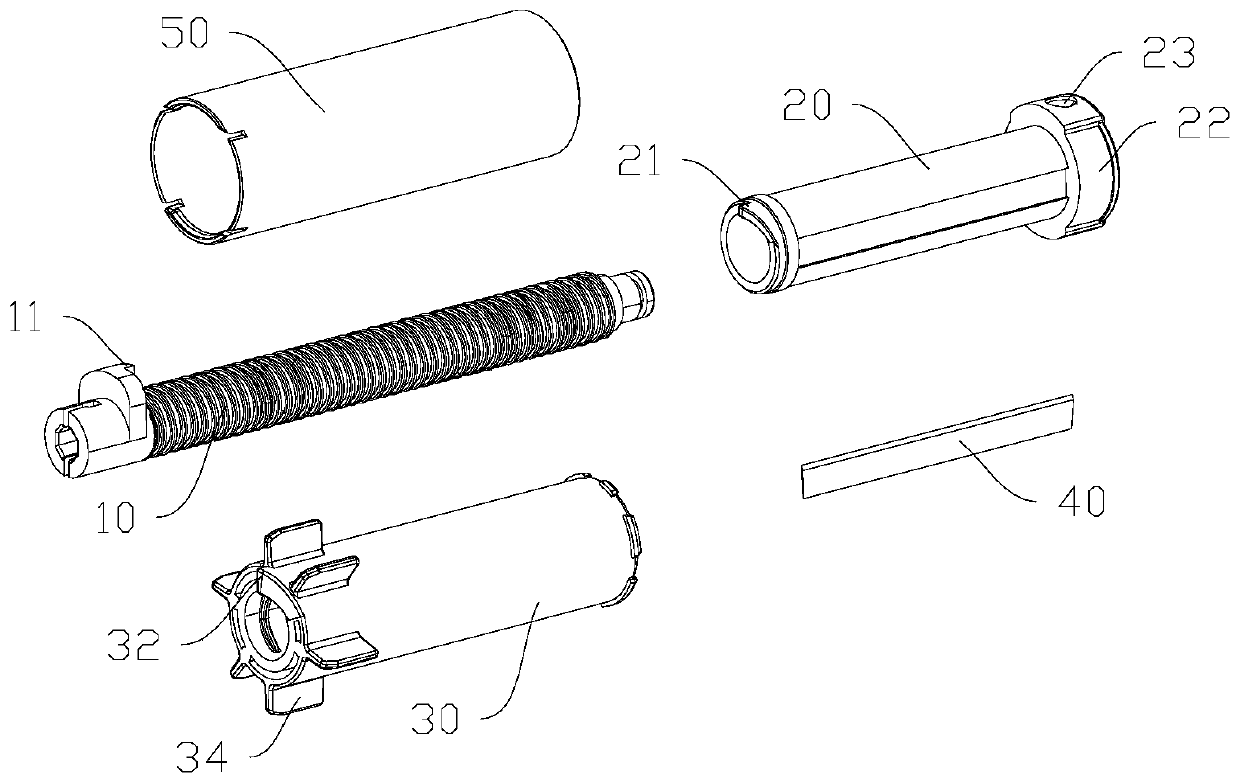

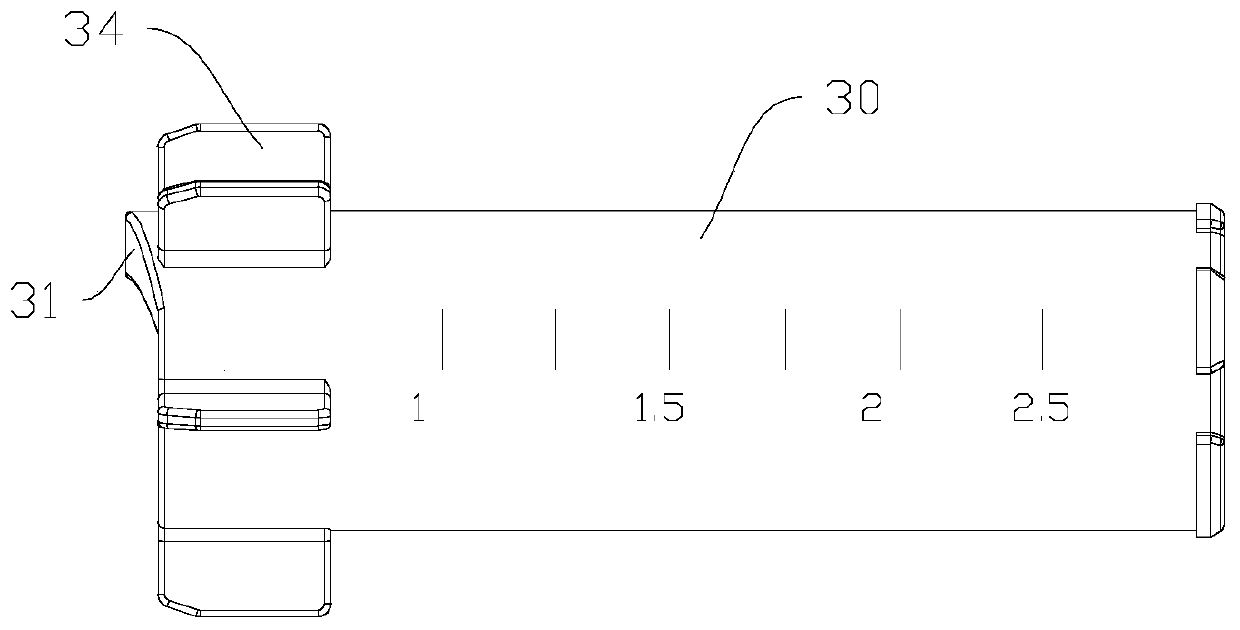

[0029] refer to Figure 1 to Figure 4 , the roller blind balance regulator in this embodiment includes a limit screw 10 , a mandrel 20 and a friction cylinder 30 . The mandrel 20 is provided with a mandrel through hole along the axial direction, and the limit screw 10 passes through the mandrel through hole and is fixed therein. An annular protrusion 22 is provided on the outside of the second end of the mandrel 20 , and at least one countersunk screw hole 23 is provided on the annular protrusion 22 , and the hole axis of the countersunk screw hole 23 is perpendicular to the limit screw 10 . The annular protrusion 22 can be integrally formed with the mandrel 20 . The bolt is screwed into the countersunk screw hole 23 , and the bottom end of the bolt abuts against the limit screw 10 , thereby fixing the relative position of the mandrel 20 and the limit screw 10 . The mandrel 20 is inserted into the friction cylinder 30. Preferably, the inside of the friction cylinder 30 is pr...

Embodiment 2

[0039] refer to Figure 5 , the roller blind balance adjuster in this embodiment differs from the first embodiment only in that the mandrel 20 and the limit screw 10 together form an integrally formed stepped shaft. The small-diameter end of the stepped shaft is provided with threads, the friction cylinder 30 is threadedly connected with the small-diameter section of the stepped shaft, and a friction layer is arranged between the friction cylinder 30 and the large-diameter section of the stepped shaft. This setting can avoid the abrasion caused by the mutual collision between the mandrel 20 and the limit screw 10, and simplify the structure.

Embodiment 3

[0041] refer to Figure 6 , the roller blind balance adjuster in this embodiment, which includes a fixing piece 60 and a friction cylinder 30 for connecting with a roller blind rod. The fixing member 60 includes a sleeve 62 and a central rod 61 fixed in the sleeve 62, the central rod 61 is arranged along the axial direction of the sleeve 62, and a space capable of accommodating the insertion of the friction cylinder 30 is formed between the sleeve 62 and the central rod 61 . Optionally, the central rod 61 and the sleeve 62 can be integrally formed. The friction cylinder 30 has an inner surface and an outer surface, one of the sides of the friction cylinder 30 is screwed to the fixing member 60 , and a friction layer is provided between the other side of the friction cylinder 30 and the fixing member 60 . The friction cylinder 30 is inserted into the space between the sleeve 62 and the central rod 61 , and the central rod 61 passes through the friction cylinder 30 . Optional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com