Shaft end motor of automobile electric control hydraulic independent shaft end driving system

A driving system and electronic control technology, applied in variable displacement engines, machine/engines, reciprocating piston engines, etc., can solve the problems of easy sideslip, low hydraulic motor speed, large space, etc., and achieve stable speed regulation, The effect of torque balance and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

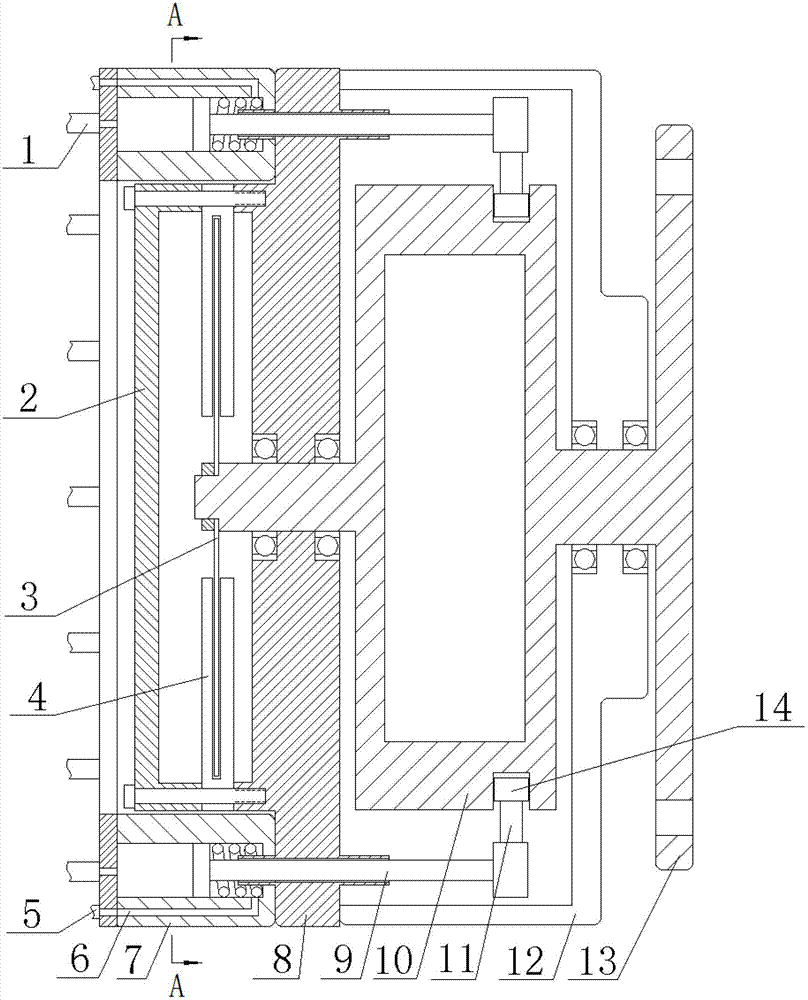

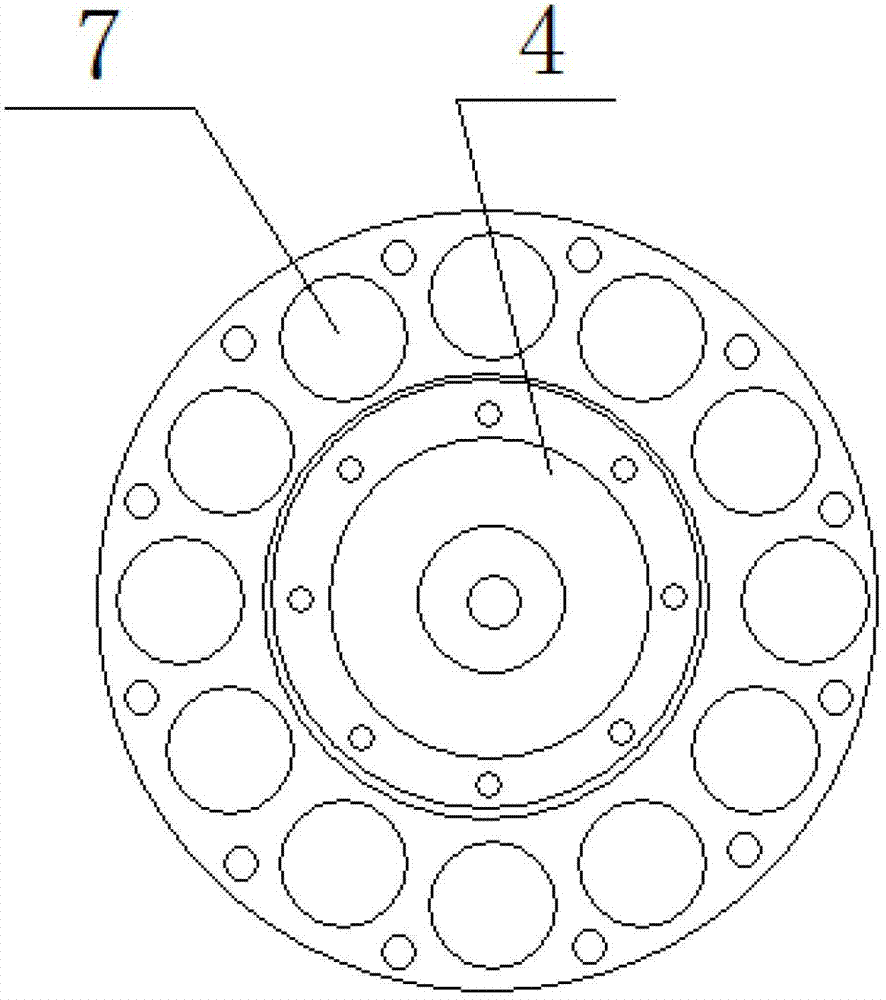

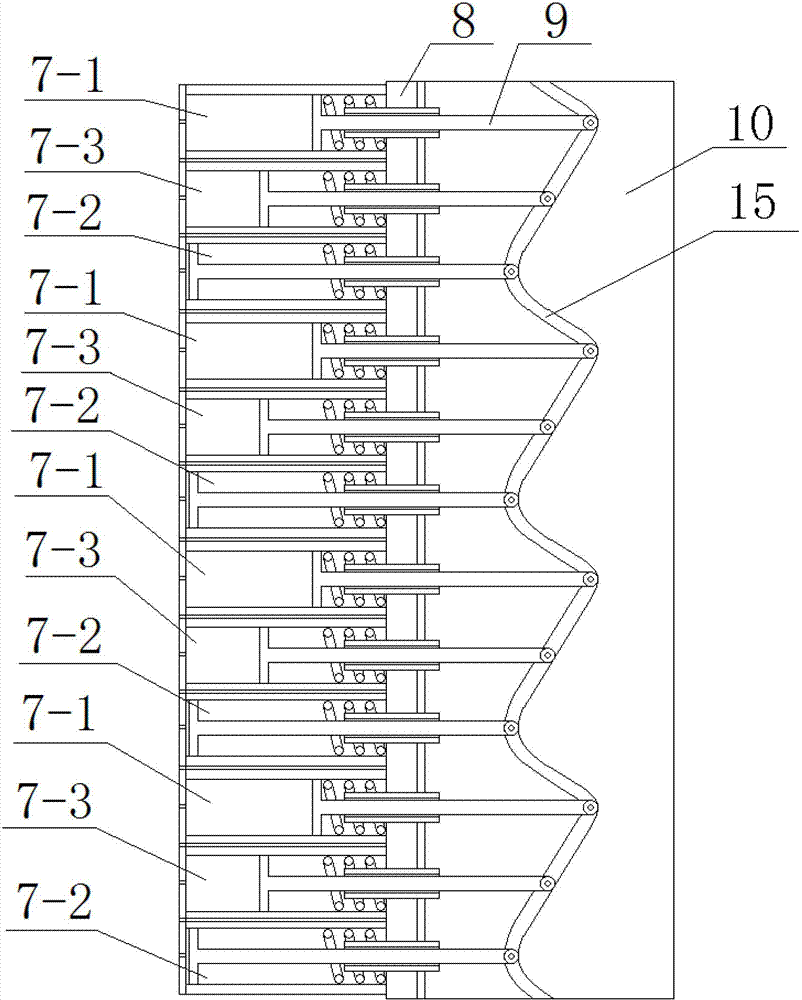

[0013] Such as figure 1 and figure 2 As shown in the figure, the axle-end motor of the automobile electronically controlled hydraulic independent axle-end drive system includes a hydraulic cylinder 7, a main engine, a code disc 3 and a sensor frame 4; its characteristic is that several hydraulic cylinders 7 are perpendicular to and fixed to the inner end cover On the inner end cover 8, and arranged in a circular shape, the end of each hydraulic cylinder piston rod 9 is connected with a push rod 11 perpendicular to the wheel axis, one end of the push rod is fixedly connected to the end of the piston rod, and the other end Connect with slide block 14 through bearing; Described main engine comprises rotor 10 and housing 12, and wherein rotor is cylindrical, as image 3 As shown, a wavy groove 15 is provided on the side of the cylinder; a corresponding number of push rod guide grooves are set on the inner wall of the housing; the slider moves in the wavy groove; as figure 1 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com