Steaming device for textile printing and dyeing and steaming method thereof

A steaming and fabric technology, applied in textiles and papermaking, textile processing machine accessories, textile material processing, etc., can solve problems such as color difference defects, ensure accuracy and stability, optimize process, and improve product quality and block effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

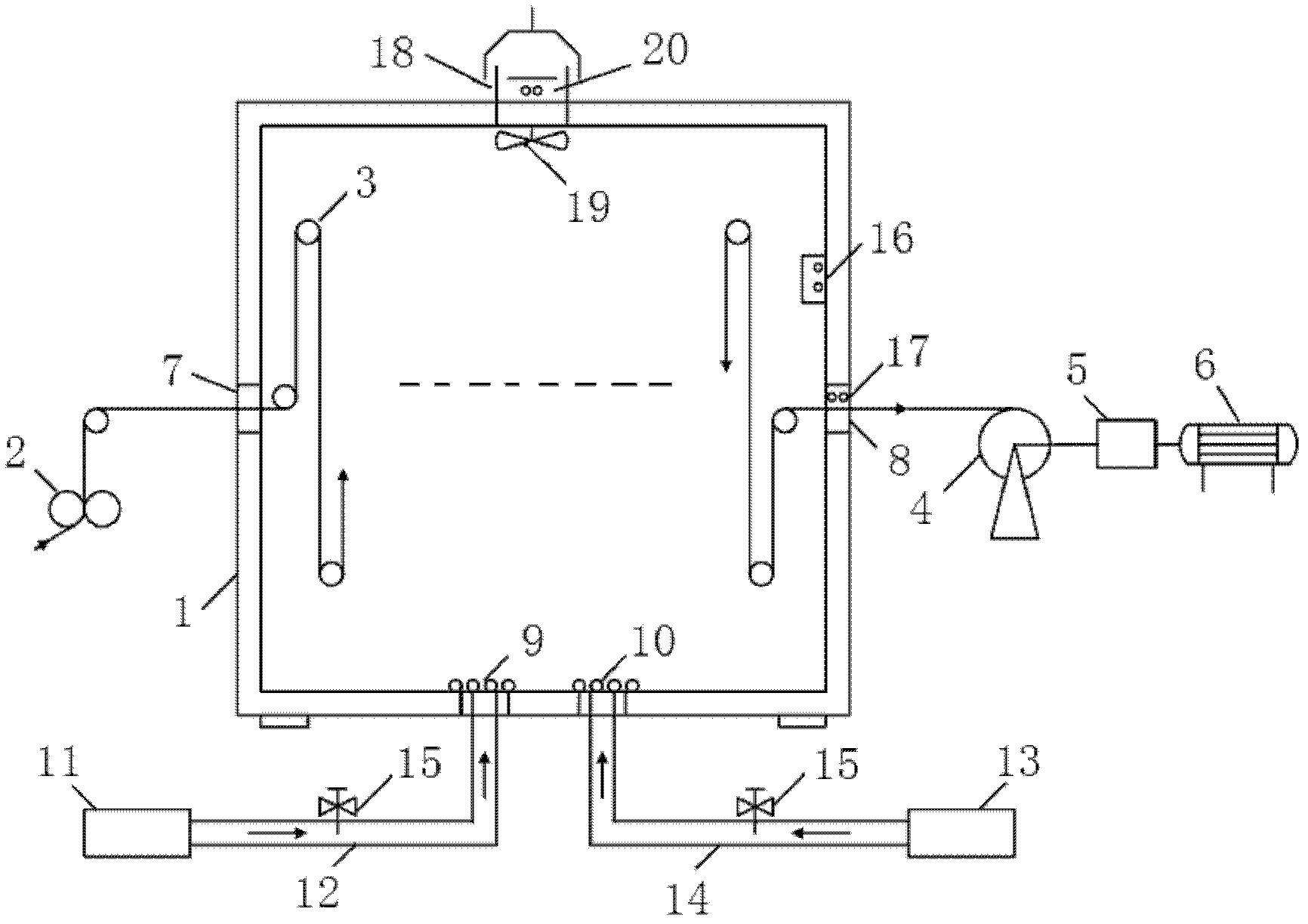

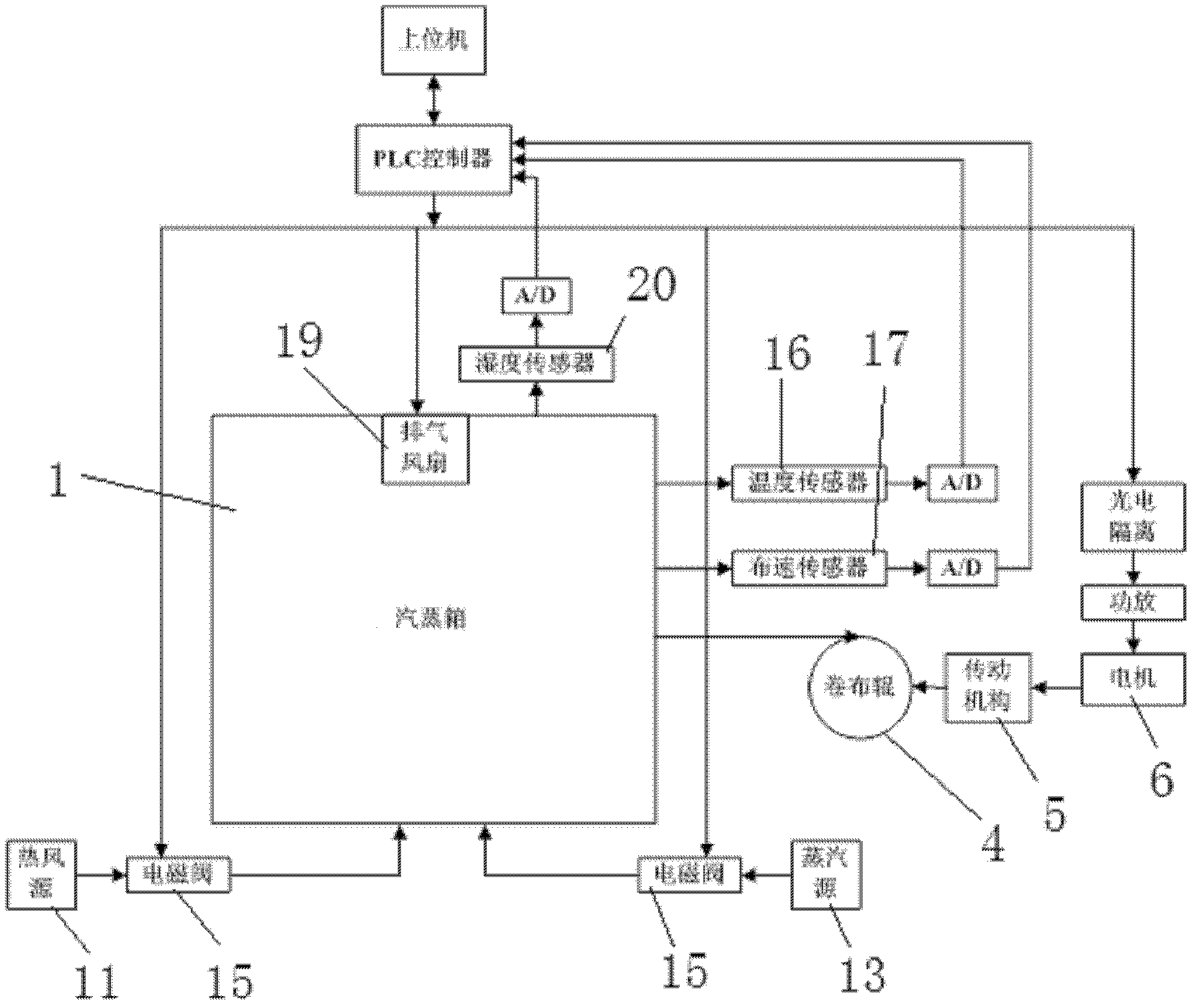

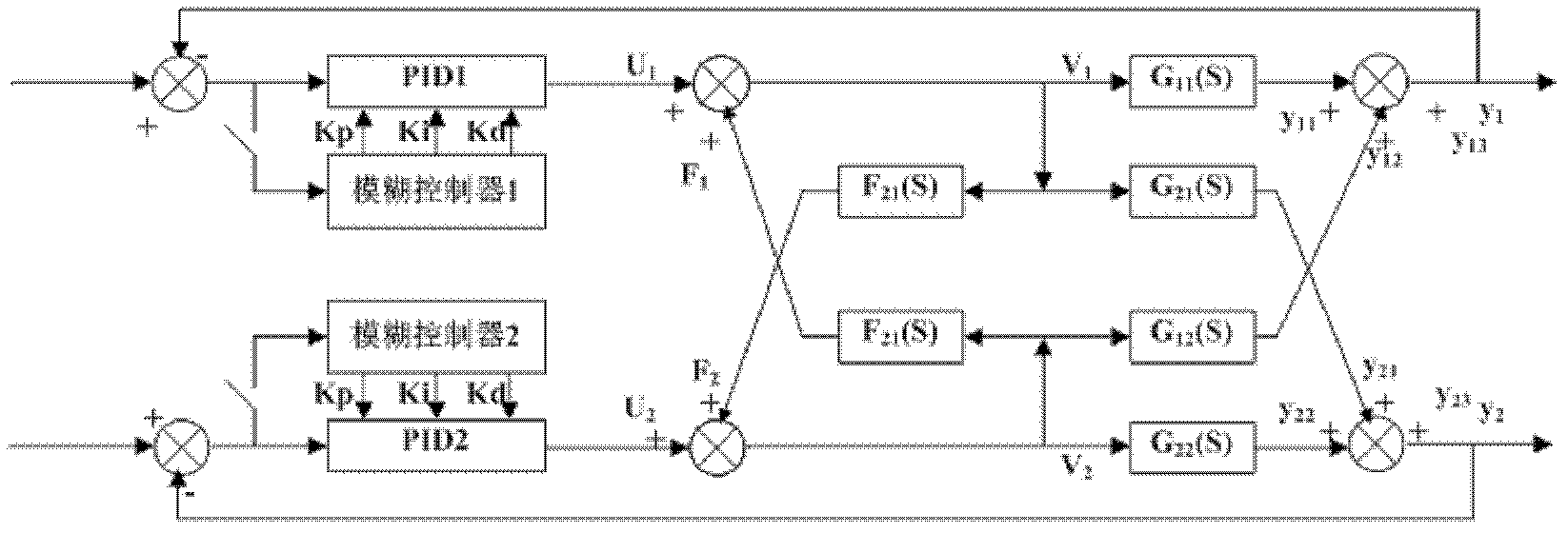

[0028] Such as Figure 1 ~ Figure 2 A fabric printing and dyeing steaming device shown includes a steaming box 1, a padding car 2, a cloth guide roller 3, a cloth rolling roller 4, and a motor 6 that controls the cloth rolling roller 4 through a transmission mechanism 5. The steaming box 1 is provided with Cloth inlet 7 and cloth outlet 8, the case wall of steaming box 1 is provided with hot blast inlet 9 and steam inlet 10, and hot blast inlet 9 is connected with the hot blast pipeline 12 that is connected with hot blast source 11, and steam inlet 10 is connected with The steam pipes 14 of the steam source 13 are connected. The hot air pipeline 12 and the steam pipeline 14 are respectively provided with solenoid valves 15 . The hot air inlet 9 and the steam inlet 10 are respectively provided with spouts. The steam box 1 is provided with a temperature sensor 16 . The cloth outlet 8 of the steam box 1 is provided with a cloth speed sensor 17, and the cloth speed sensor 17 ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com