Integral lowering and removing system of span box girders based on bridge deck support and construction method of integral lowering and removing system

A construction method and cross-box technology, applied in bridges, bridge maintenance, bridge reinforcement and other directions, can solve the problems of high cutting costs, increased hoisting weight, difficult hoisting and transportation, etc., to reduce cutting area, reduce demolition costs, and have good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

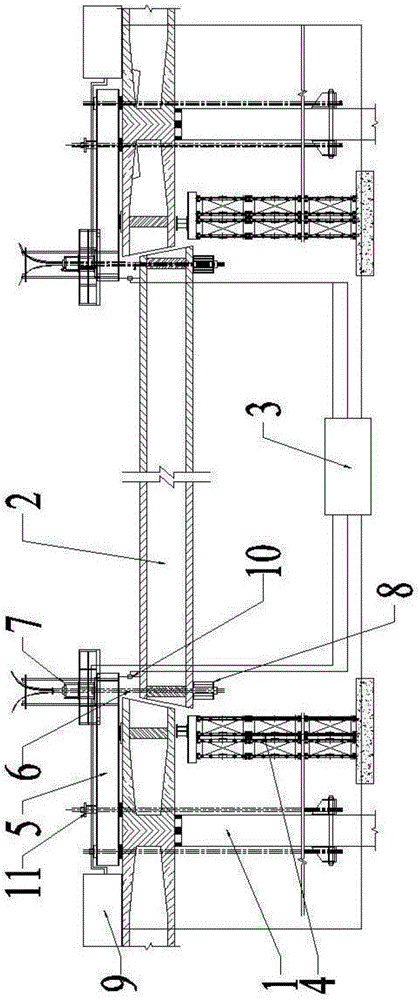

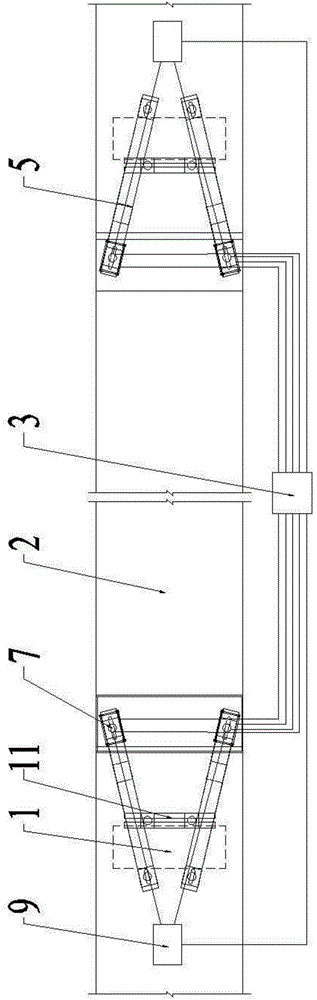

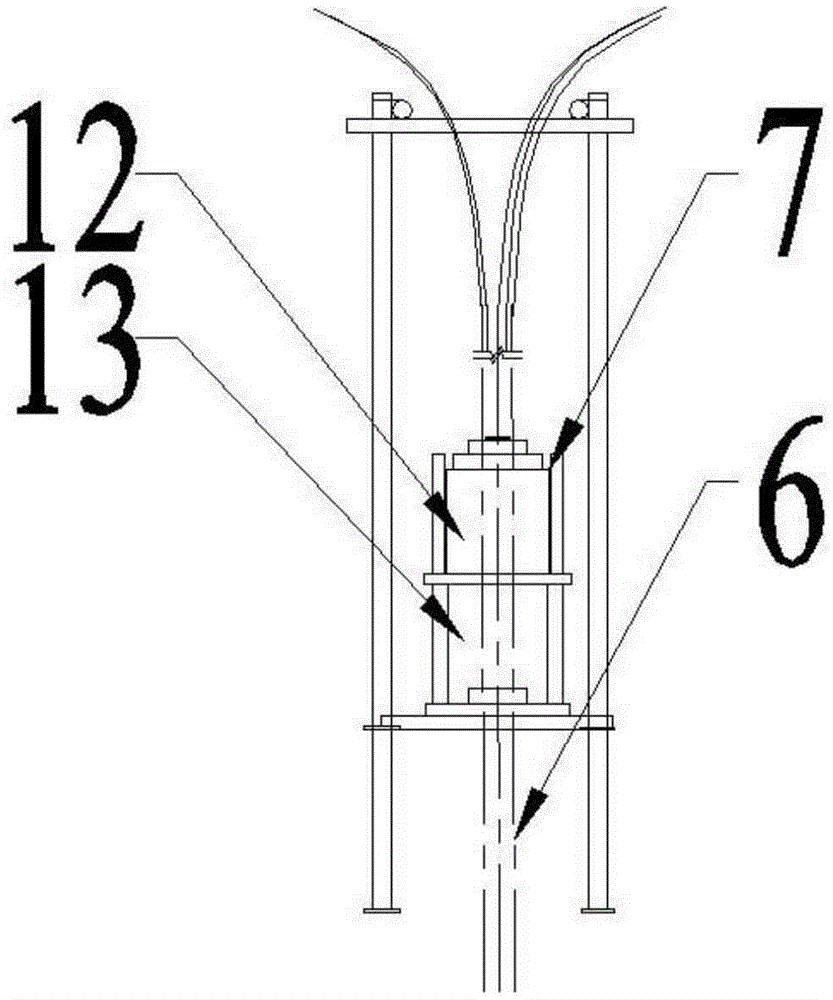

[0032] Such as Figure 1-8 As shown, the whole-span box girder demolition system based on bridge deck support uses the pier column 1 as the bearing support, and the pier column 1 as the support point of the lowered box girder 2 to complete the demolition of the entire large-tonnage bridge. Among them, two sets of cantilever reaction force systems symmetrically arranged at both ends of the lowered box girder 2 are included. The cantilever reaction force system includes two main cantilever beams 5 and slings 6 .

[0033] Such as figure 2 As shown, the two main cantilever beams 5 are arranged horizontally, in a mutual horizontal or "eight" arrangement, and one of the similar ends is anchored on the pier column 1, and the ends of the main cantilever beams 5 are connected with steel wire ropes, which pass through the box girder and the pier The fixed structure on the column 1 is connected, and the fixed structure on the pier column 1 is connected with the pier column 1 by bolts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com