Processing device for intensive bus insulating film pin notch and operation method

A technology of insulating film and processing device, applied in the direction of manufacturing tools, pliers, etc., can solve the problems of large working space, poor forming effect, multi-person operation, etc., and achieve the effect of small working space, easy control, and small cutting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

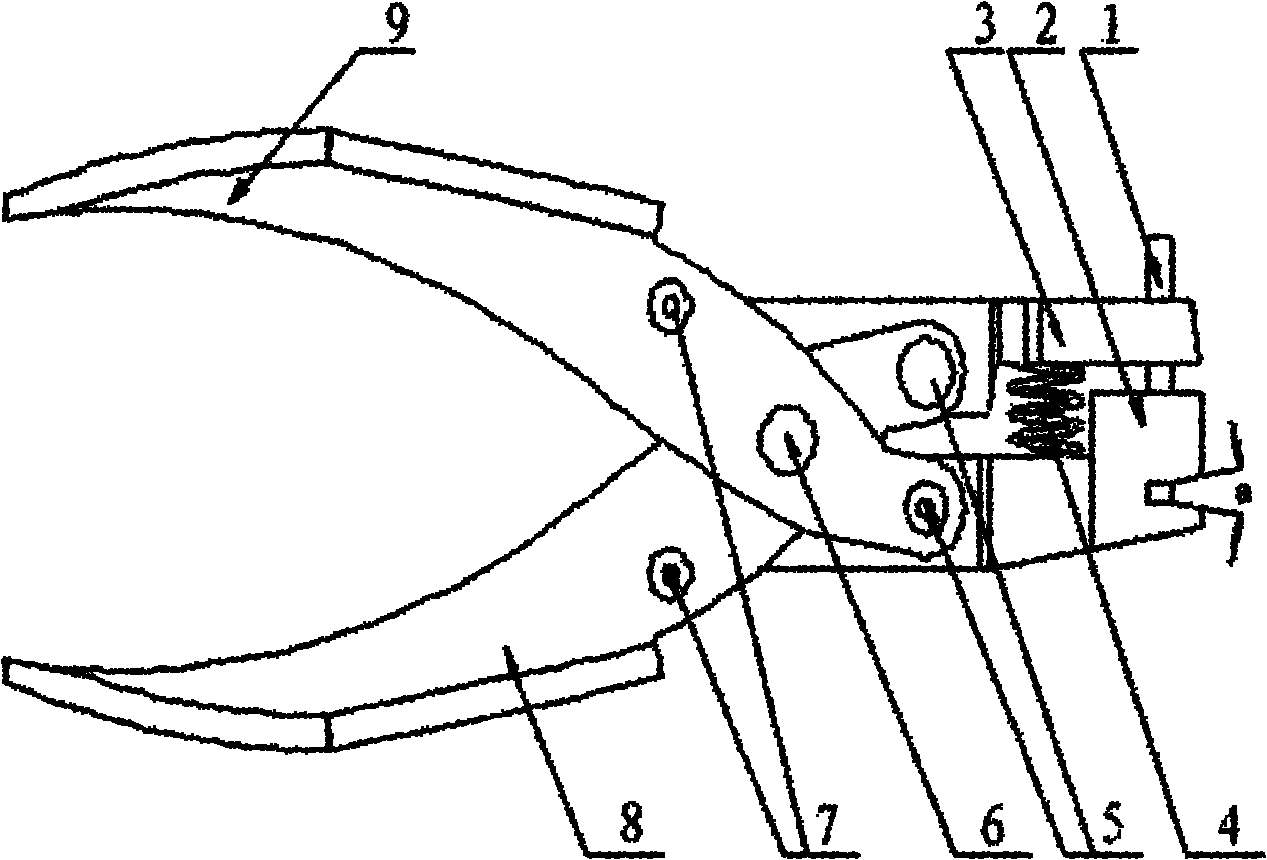

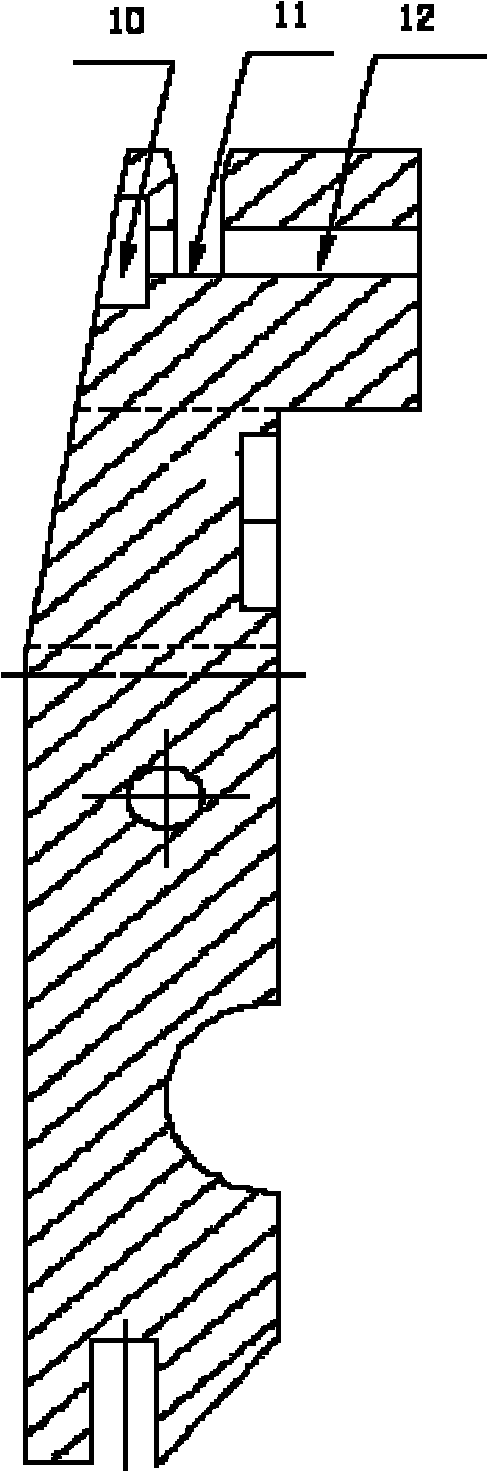

[0021] As shown in the figure, the present invention firstly designs a processing device for pin incision of intensive busbar insulation film, which mainly includes incision tool 1, which is the punch, incision tool holder 2, which is the die, power tool holder 3, return spring 4, Hollow rivet 5, rotating shaft 6, guiding and positioning shaft 7, lower operating handle 8, upper operating handle 9; wherein the lower operating handle 8 and the upper operating handle 9 are connected through the rotating shaft 6, and the lower operating handle 8 and the upper operating handle 9 The guide positioning shaft 7 is installed on the top, and the lower operating handle 8 and the upper operating handle 9 are connected with the power knife rest 3 and the incision knife rest 2, that is, the die through the hollow rivet 5; after the lower operating handle 8 and the upper operating handle 9 are relaxed, The incision tool 1, that is, the punch and the incision tool holder 2, that is, the die, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com