Efficient and consumption-reducing stone cutting machine

A stone cutting and cutting machine technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of unsuitable large-scale cutting of luxury stone blocks, easy back and forth vibration of saw blades, and large volume of luxury stone blocks. Achieve the effects of reducing cutting costs, improving aesthetics, increasing output and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

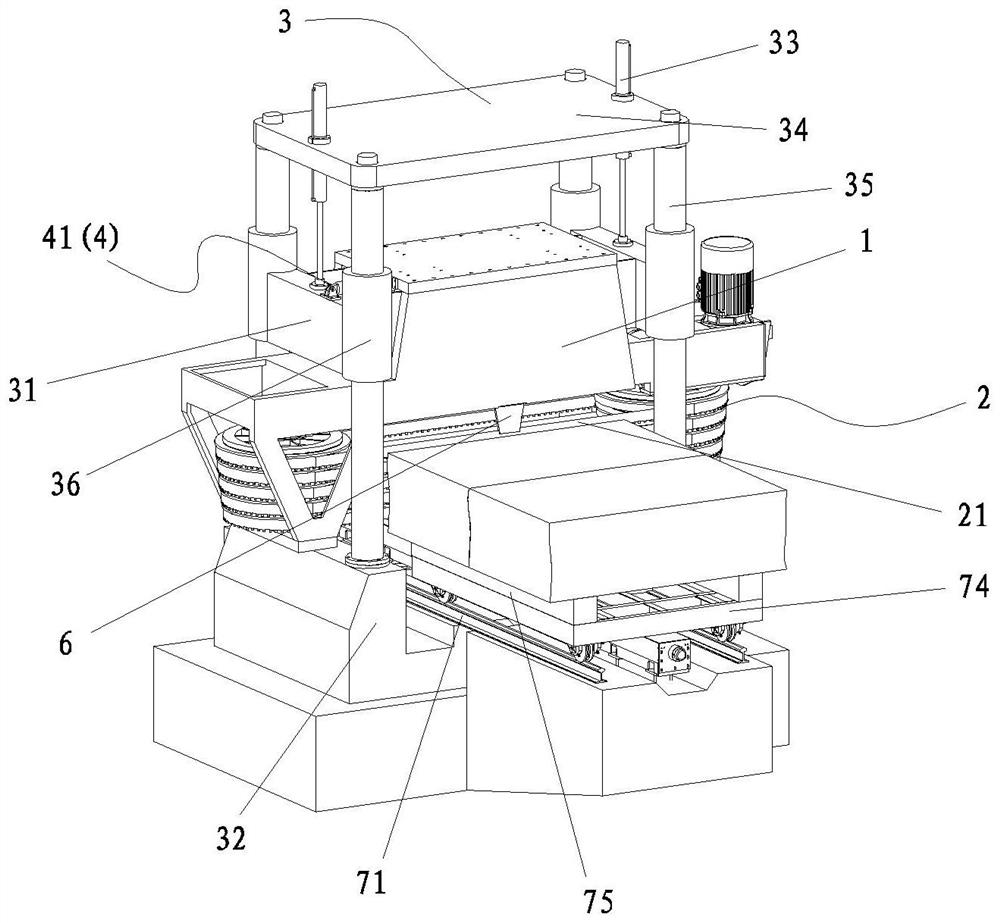

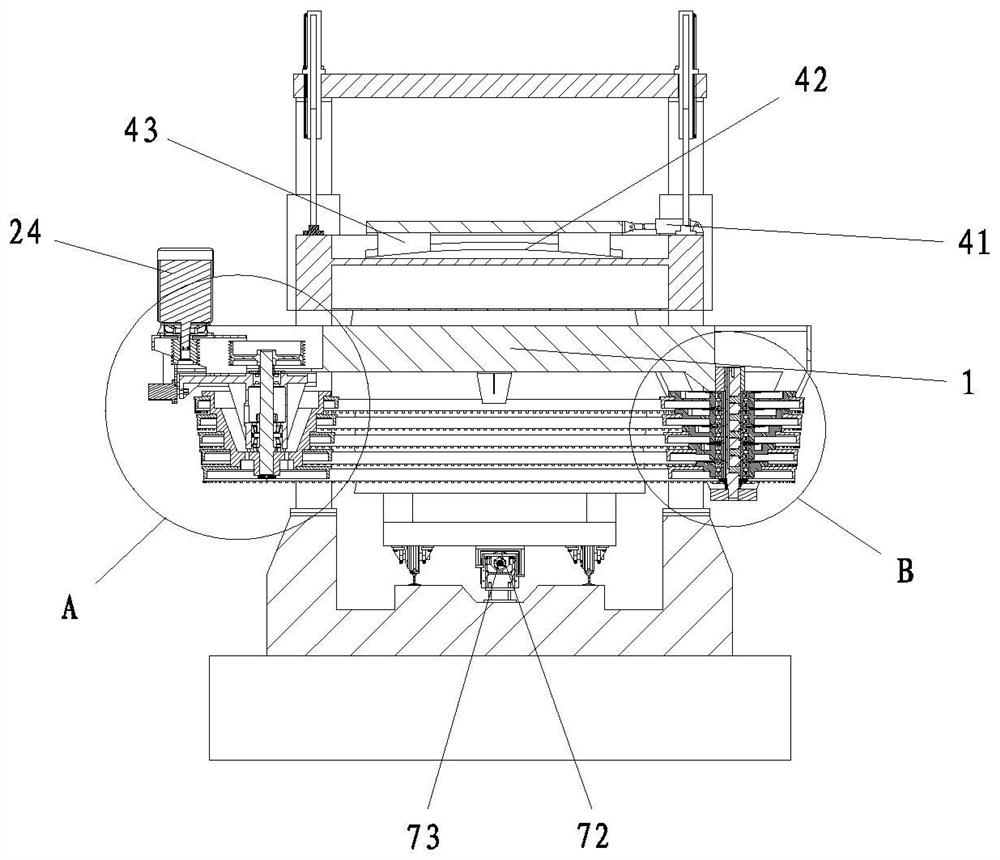

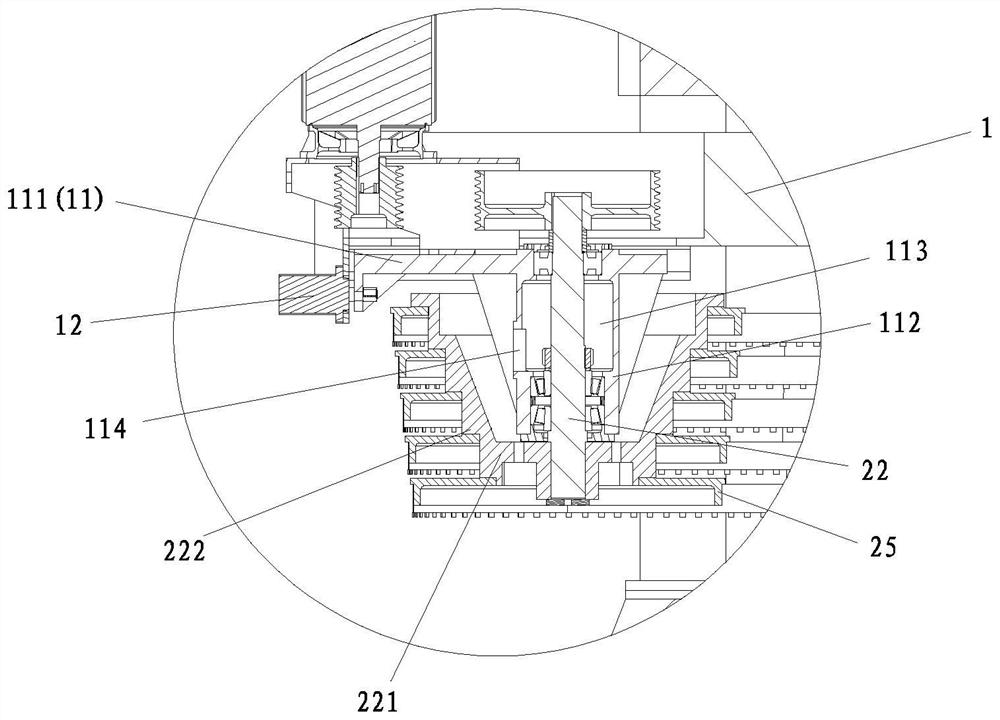

[0041] Such as Figure 1-5 As shown, a stone cutting machine with high efficiency and consumption reduction includes a stone conveying mechanism and a stone cutting mechanism. The stone cutting mechanism is arranged above the stone conveying mechanism. The stone cutting mechanism includes a frame and a saw mounted on the frame Belt cutting device, the stone conveying mechanism automatically transports large blocks to the bottom of the stone cutting mechanism, and then the saw band 2 cutting device drives the saw band 21 to cut the stone. Compared with the prior art, the present invention can realize the automatic cutting of large-scale blocks by cutting with the saw band 21, so that the cutting area of the cutting machine is smaller, and at the same time, the cutting efficiency and cutting quality are improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com