Tunnel crack detecting and repairing device

A technology for tunnels and cracks, which is applied in the field of tunnel crack detection and repair devices, and can solve the problems of reducing the repair range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

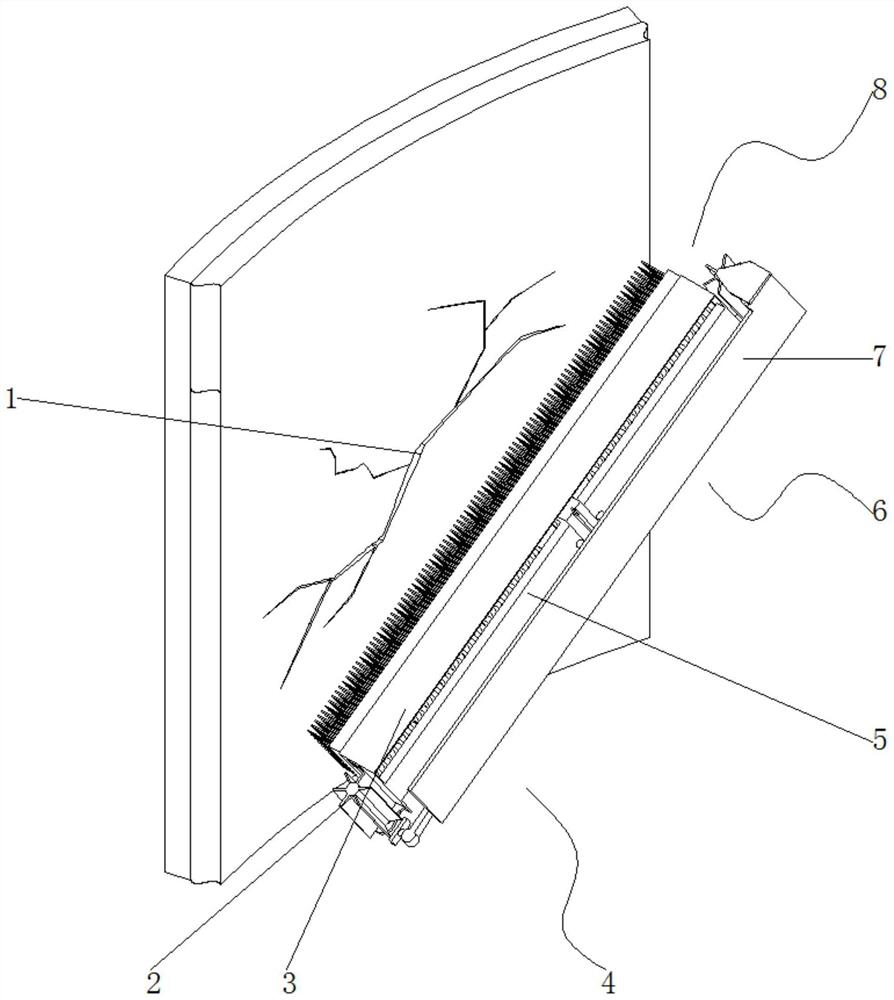

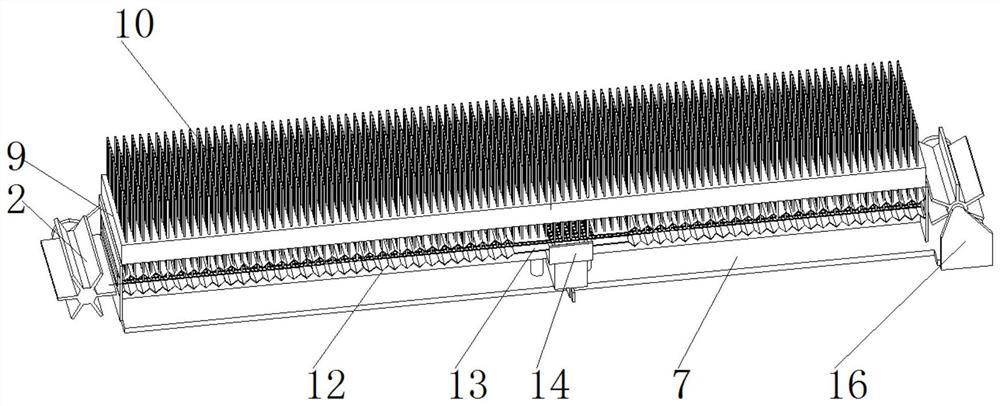

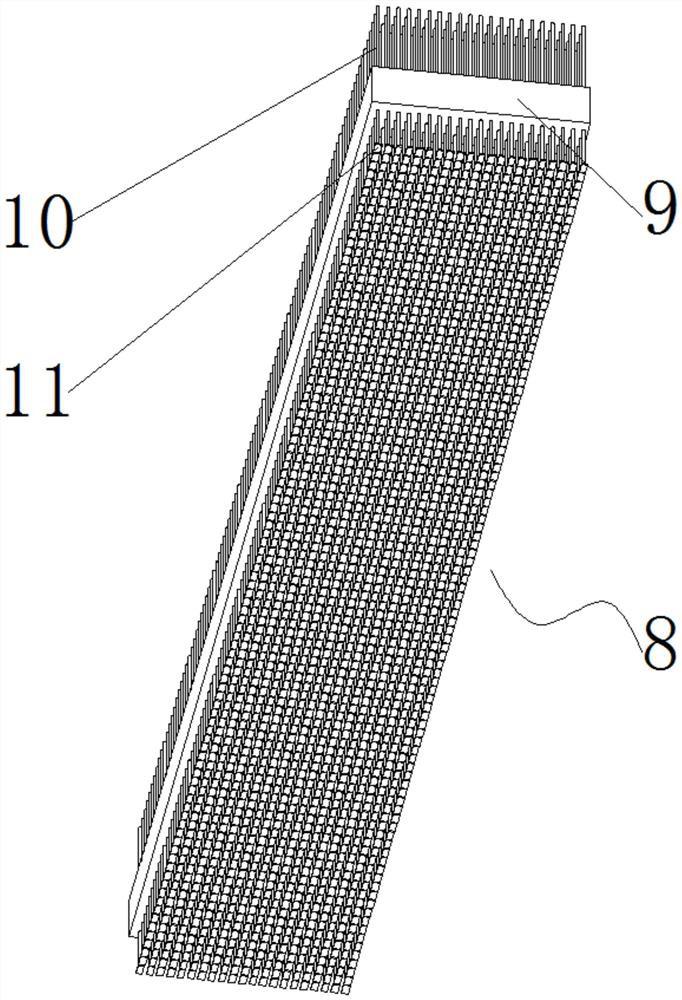

[0022] An embodiment of the present invention provides a tunnel crack detection and repair device, such as Figure 1-7 As shown, set on crack 1. It includes a pre-detection mechanism 4 and a repair grinding mechanism 28 , both of which correspond to the crack 1 , and the pre-detection mechanism 4 includes a detection assembly 8 and a drive assembly 6 . The detection assembly 8 is connected to the driving assembly 6 , and the detection assembly 8 corresponds to the crack 1 . The detection assembly 8 includes an inserting board 9 , a plurality of baffles 11 and an inserting rod 10 , the inserting board 9 is connected to the drive assembly 6 , and a plurality of inserting rods 10 are movably inserted in the inserting board 9 along the height direction of the inserting board 9 . The baffles 11 are arranged at the bottom of the insertion rod 10 , and the edges of two adjacent baffles 11 are in contact with each other. The driving assembly 6 includes a bottom plate 7, a housing 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com