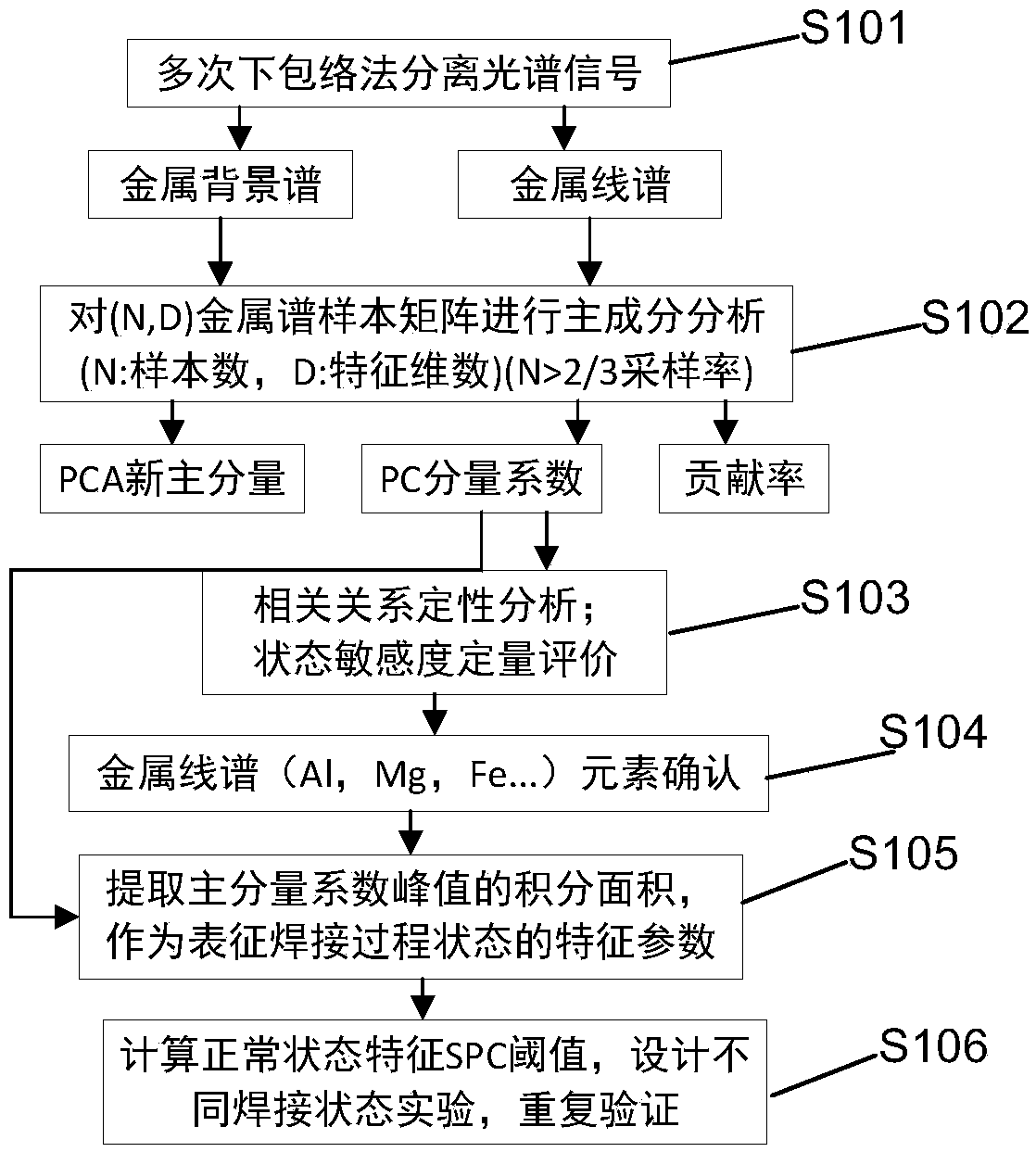

Aluminum alloy fusion welding process state detection method and device

A process state and detection method technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of no uniqueness, fuzzy correlation, etc., and achieve the requirements of maximum robustness, lower resolution, The effect of overcoming device accuracy drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

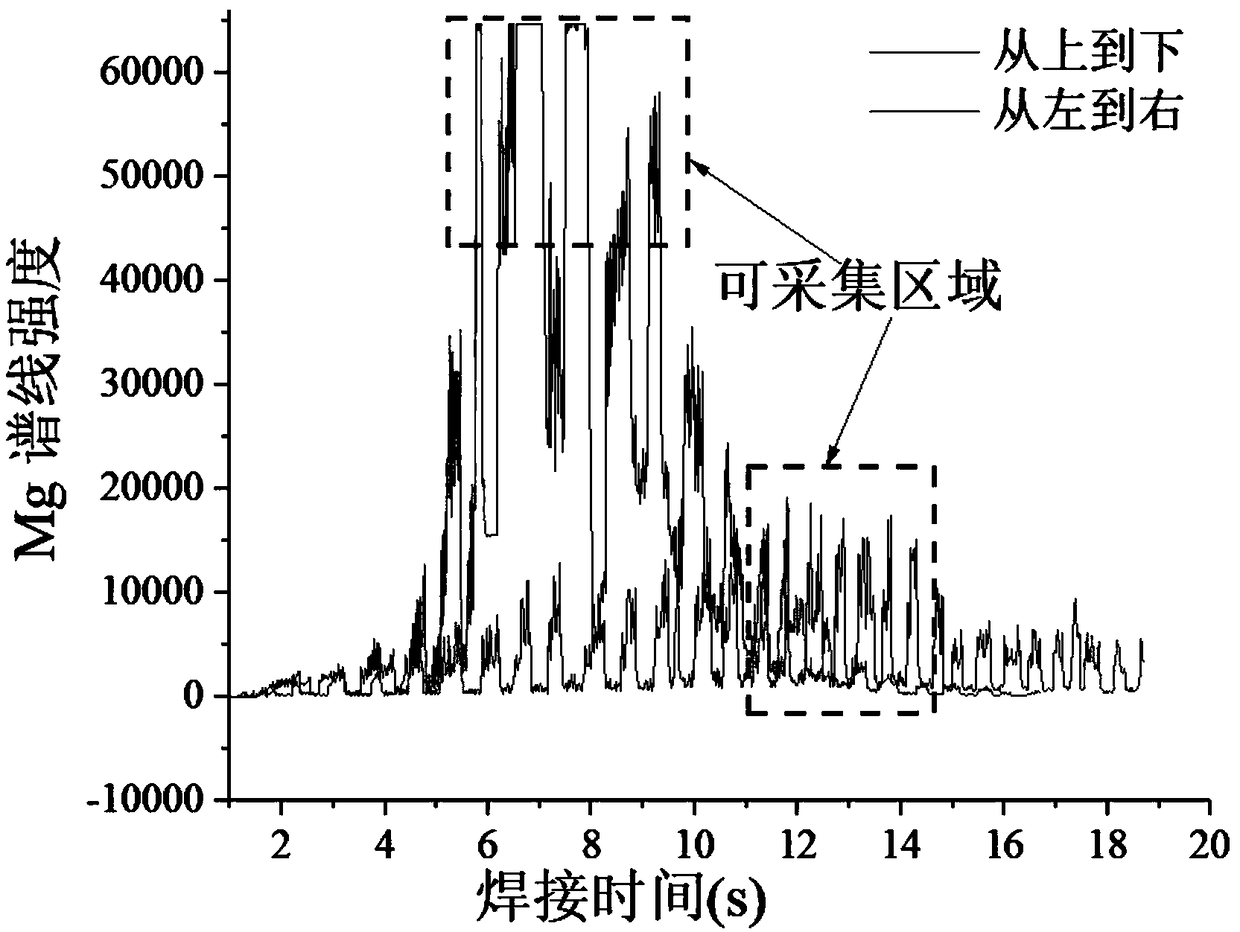

[0040] Step S1, use a fixture to fix the workpiece 3 on the workbench, install the welding torch 1 on the end axis of the robot, and set the distance between the tungsten electrode and the workpiece to 100 mm to ensure the arc 2 with the required arc length; the spectrometer probe 4 is rigidly fixed on the bracket Above, the optical fiber 5 connects the probe and the spectrometer 6, and the spectral information of the arc 2 is collected in real time and transmitted to the computer 7 via USB. Spectrometer 6 is a fiber optic spectrometer (AvaSpec-1350F-USB2), with a collection range of 350nm-1100nm, 1350 CCD pixels, an integration time of 1.5ms, and a sampling rate of about 70Hz.

[0041] In step S2, pulse tungsten argon arc welding with butt open Y-shaped groove wire filling is adopted, the peak current is 240A, the base value current is 50A, the pulse frequency is 1Hz, the wire feeding speed is 12mm / s, and the flow rate of the shielding gas argon is 15L / min, tungsten electrode...

Embodiment 2

[0058] Using the same welding process parameters as in Example 1, a part of the metal was milled off the front of the second half of the workpiece to simulate different penetration states. Welding starts welding preheating in situ for 8 seconds, without wire feeding, it lasts until 3 pulses after walking, then starts continuous wire feeding for about 20 seconds, and then stops wire feeding until the end of welding; as attached Figure 10 The physical picture of the weld is shown in the figure, the workpiece design and the results of the welding sample.

[0059] Calculated by the method of the present invention, Figure 10 The metal spectrum FeI characteristic parameter curve shown is corresponding to the analysis of different welding states. Under the coupling of the non-wire feeding state C and the welding leakage state D, the characteristic curve is still relatively stable, and there is no response to the welding leakage defect. When the wire is feeding, there is a large am...

Embodiment 3

[0061] Using the same welding process parameters as in Example 1, the surface of the weldment is polished to remove the oxide film, and the grinding debris is removed by wiping with absolute ethanol. The workpiece is fixed on the welding workbench, and the weld is as follows Figure 11 As shown, fixed-point filling of asphalt is carried out at three points E to simulate pore defects. There is no wire feeding for the first 11 pulses, and no wire feeding for the first half of the subsequent weldment, and no wire feeding for the second half. Calculate characteristic parameters according to the method of the present invention, compare with SPC threshold line after normalization, as Figure 12 As shown, the eigenvalues of the state A without wire feeding in the early stage and the state C without wire feeding in the second half are near the threshold line, while the eigenvalues of the wire feeding state B far exceed the threshold value, and the asphalt interference state E has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com