Equipment and method of envelope method processing film slitting chamfering

A technology of envelope method and processing method, which is applied in the field of envelope method for processing the reverse bevel of film pieces, can solve the problems of excessive corner material, low work efficiency, inconvenient operation, etc., and achieve the goal of material saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

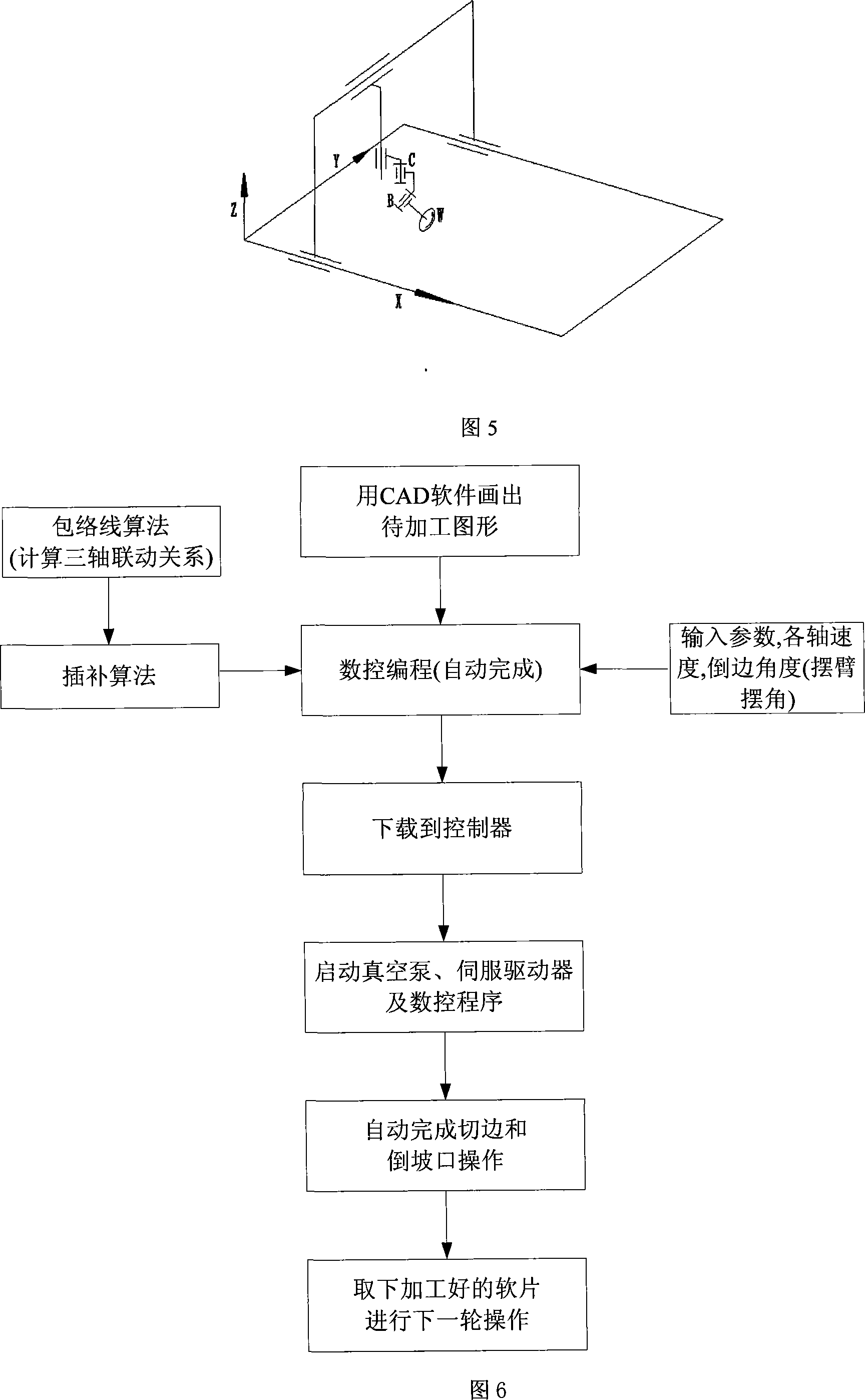

[0068] as attached image 3 , 4As shown, a device for processing the reverse bevel of film cut pieces by envelope method, including vacuum suction cup 1, x-axis rolling guide rail 2, x-axis ball screw 3, x-axis servo motor 4, z-axis servo motor 5, lift Arm 6, rotary tool post 7, main arm 8, y-axis rolling guide 9, y-axis servo motor 10, y-axis ball screw 11, z-axis ball screw 12, z-axis rolling guide 13, rotary tool post servo motor 14 , swing arm 15, disc cutter 16, swing shaft stepper motor 17, spindle motor 18, bed 19, forearm 20 and electrical control device. The vacuum suction cup 1 for fixing the film material is set on the vacuum chamber of the bed, the rolling guide rails and ball screws of the x-axis are fixed on both sides of the bed, and the large arm 8 is set on the bed through the guide rails 2 and sliders on both sides of the bed. On the bed, the boom 8 can be moved back and forth through the synchronous drive of two servo motors 4. The small arm 20 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com