Preparing and applying method for negative oxygen ion microcapsules for fabric

A technology of negative oxygen ions and application methods, applied in the field of preparation and application of negative oxygen ions, can solve the problems of not being washable and single application, and achieve the effect of overcoming single application and not washable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

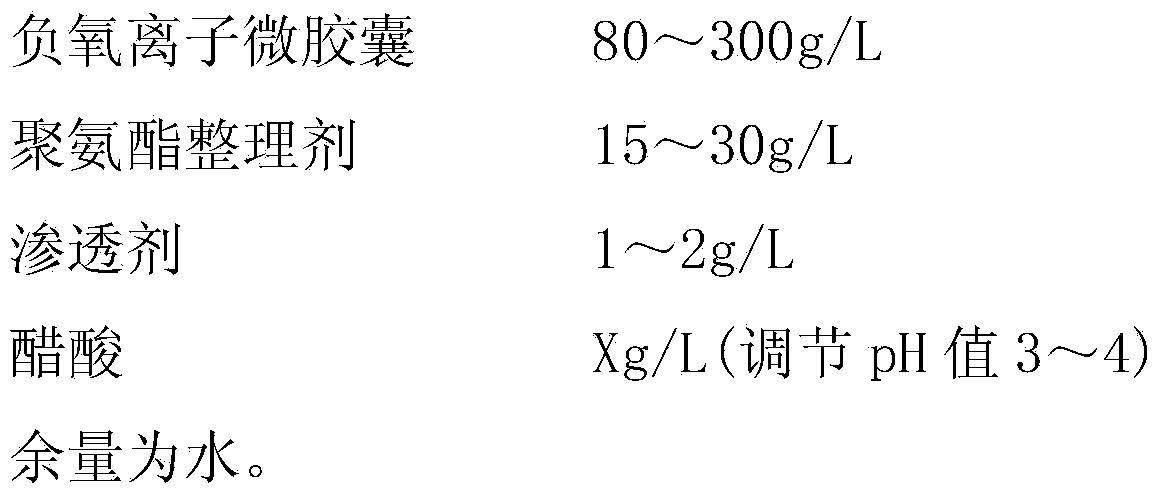

Method used

Image

Examples

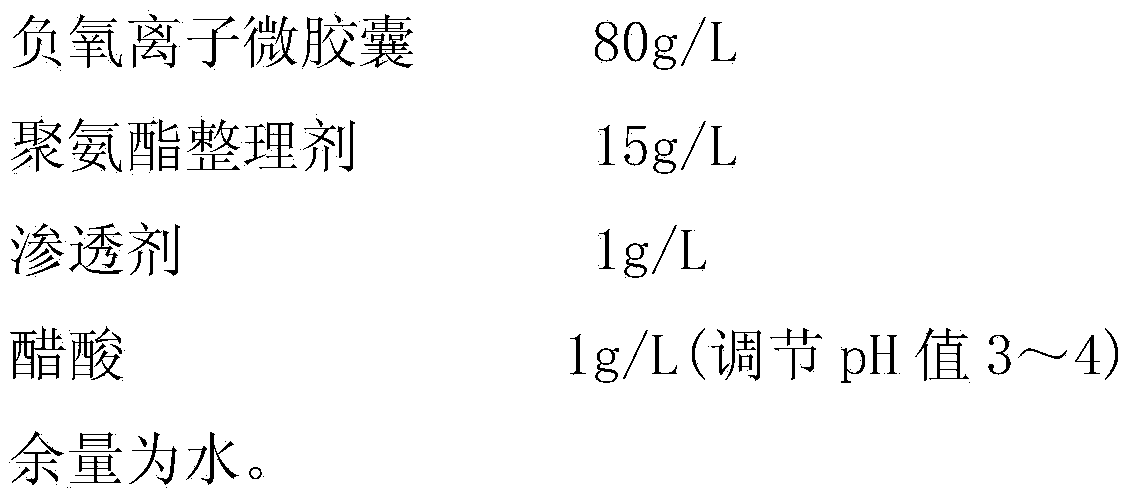

Embodiment 1

[0023] The invention discloses a method for preparing negative oxygen ion microcapsules for fabrics, comprising preparation of negative oxygen ion core materials, selection of microcapsule wall materials and preparation of microcapsule solutions.

[0024] The raw materials of the negative oxygen ion core material are tourmaline and TiO 2 Grind the raw material of the negative oxygen ion core material with a grinder, then place it in a certain amount of distilled water, stir it with a mixer for 0.5h, and then grind it with a nano-grinding rod grinder. The grinding medium uses 0.3mm zirconia beads. Finally filter and dry.

[0025] The microcapsule wall material is β-cyclodextrin;

[0026] The microcapsule wall material is formulated into a solution with a certain concentration, and then the nano-core material, distilled water, and absolute ethanol are added in proportion, stirred at a rotation speed of 1080 rpm and a temperature of 40° C. for 3 hours, cooled and left standing t...

Embodiment 2

[0033] The invention discloses a method for preparing negative oxygen ion microcapsules for fabrics, comprising preparation of negative oxygen ion core materials, selection of microcapsule wall materials and preparation of microcapsule solutions.

[0034] The raw materials of the negative oxygen ion core material are opal and TiO 2 Grind the negative oxygen ion core material raw material with a grinder, then place it in a certain amount of distilled water, stir it with a mixer for 0.8h, and then grind it with a nano-grinding rod grinder. The grinding medium uses 0.1mm zirconia beads. Finally filter and dry.

[0035] The microcapsule wall material is β-cyclodextrin and sodium alginate;

[0036] The microcapsule wall material is formulated into a solution with a certain concentration, and then the nano core material, distilled water, and absolute ethanol are added in proportion, stirred at a rotation speed of 1080 rpm and a temperature of 50° C. for 2 hours, cooled and left sta...

Embodiment 3

[0044] The invention discloses a method for preparing negative oxygen ion microcapsules for fabrics, comprising preparation of negative oxygen ion core materials, selection of microcapsule wall materials and preparation of microcapsule solutions.

[0045] The raw material of the negative oxygen ion core material is tourmaline; the negative oxygen ion core material raw material is ground with a grinder, then placed in a certain amount of distilled water, stirred by a mixer for 1 hour, and then ground with a nano-grinding rod grinder , the grinding medium uses 0.2mm zirconia beads, and finally is filtered and dried.

[0046] The microcapsule wall material is chitosan;

[0047] The microcapsule wall material is formulated into a solution with a certain concentration, and then the nano-core material, distilled water, and absolute ethanol are added in proportion, stirred for 1 hour at a rotation speed of 1080 rpm and a temperature of 60° C., cooled and left standing to form a micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com