Spherical involute spiral bevel gear cutting method and machine tool

A technology of spherical involute and spiral bevel gears, which is applied in the direction of gear cutting machines, gear tooth manufacturing tools, gear tooth manufacturing devices, etc., can solve the problem of inability to obtain spherical involute tooth shape, instantaneous speed ratio cannot be constant, and processing gears Incompatibility and other problems can be achieved to achieve the effect of diversification of cutting methods, improvement of cutting processing efficiency, and improvement of versatility

Inactive Publication Date: 2010-11-24

JILIN UNIV

View PDF1 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since the spiral bevel gears cut by the current gear cutting method cannot obtain a spherical involute tooth shape, there are many insurmountable disadvantages

Such as: the instantaneous speed ratio cannot be constant, the change of the transmission angle affects the sensitivity of the contact area, the adjustment of the contact area is difficult, the processed gears are not interchangeable, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

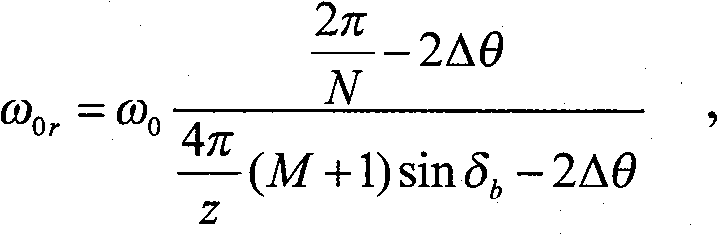

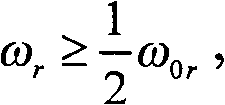

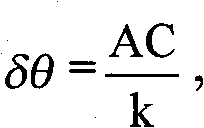

The invention discloses a cutting method for a bevel gear with spherical involute toothed circular arc teeth and a machine tool thereof. The cutting method comprises a circular arc cutter edge conjugation generating method and an envelope method. A cutter shaft and a gear blank shaft for implementing the circular arc cutter edge conjugation generating method rotate directionally with rotating rates (Omega0) and (Omega1), a cutter edge enters into cutting, a cage chair rotates according to that Omega is equal to Omega1sinaDeltab, the formation of pure rolling of a gear blank base cone and thebig circular plane of the spherical surface is guaranteed to complete the processing of spherical involute toothed flank. The cage chair with a real axis is driven to rotate by a servo motor, and forthe cage chair without a real axis, the synthesis movement of the y and z directions of a coordinate system forms a cage chair to rotate with the rotating rate (Omega). When the envelope method is implemented, cutter teeth of short arc and even point cutter edge are adopted. Points with the number of k are taken on the circular arc line AC of generating the flank, each cutting can form a spiral line on the flank, the circular arc cutting feed angle Delta Theta of a gear cutter head per cutting is set, and the flank which is composed of spiral lines with the number of k is enveloped and generated by sequentially k-times cutting feed. A third shaft and a forth shaft link a numerical control gear cutting machine to implement the gear cutting method.

Description

Spherical Involute Tooth Profile Spiral Bevel Gear Cutting Method and Machine Tool technical field The invention relates to a device for processing spiral bevel gears and a gear cutting processing method, more specifically, it relates to a gear cutting method and a machine tool for processing spherical involute tooth-shaped spiral bevel gears. Background technique Bevel gears are important transmission elements that transmit the motion and power of intersecting shafts. Theoretically, for a pair of bevel gears with correct conjugate transmission, the cone tops of the two gears are at the same point, and only the points on the tooth surface that are equidistant from the cone tops can contact each other, that is, the points on the conjugate tooth profile must be on the same spherical surface. Therefore, the profile of the tooth surface of the bevel gear should be a spherical involute. However, the spherical involute cannot be developed in the plane, and the theoretical spher...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23F9/00B23F21/00B23F23/12

CPCB23F9/10B23F21/22

Inventor 杨兆军彭福华张学成

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com