Gear cutting machine having a device for chamfering / deburring the edges of a work piece

A technology of gear cutting machine, oblique cutting, applied in the direction of gear cutting machine, components with teeth, gear tooth manufacturing device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation

[0012] The present invention has been described in detail by describing the preferred embodiment of the invention by way of example only.

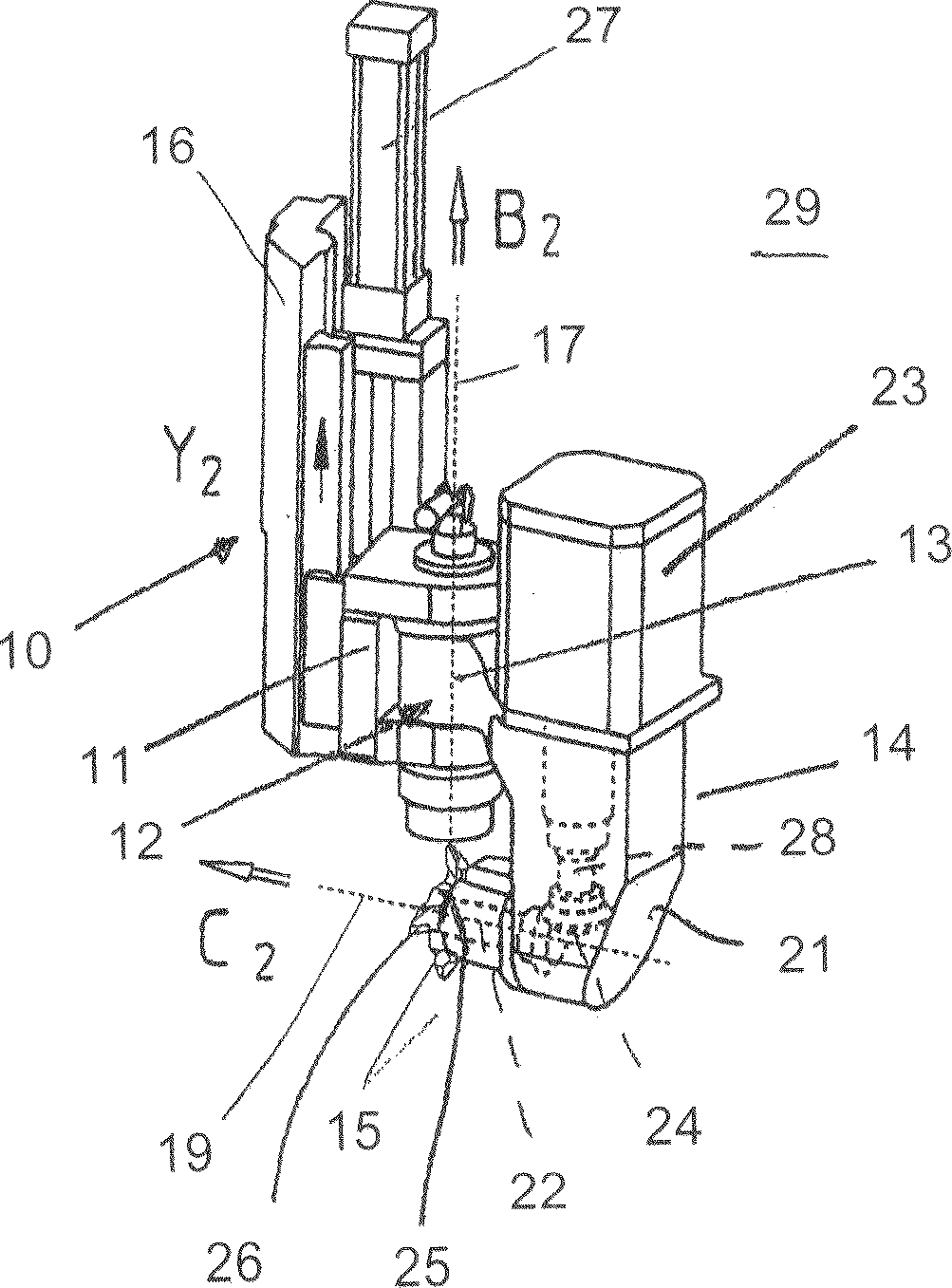

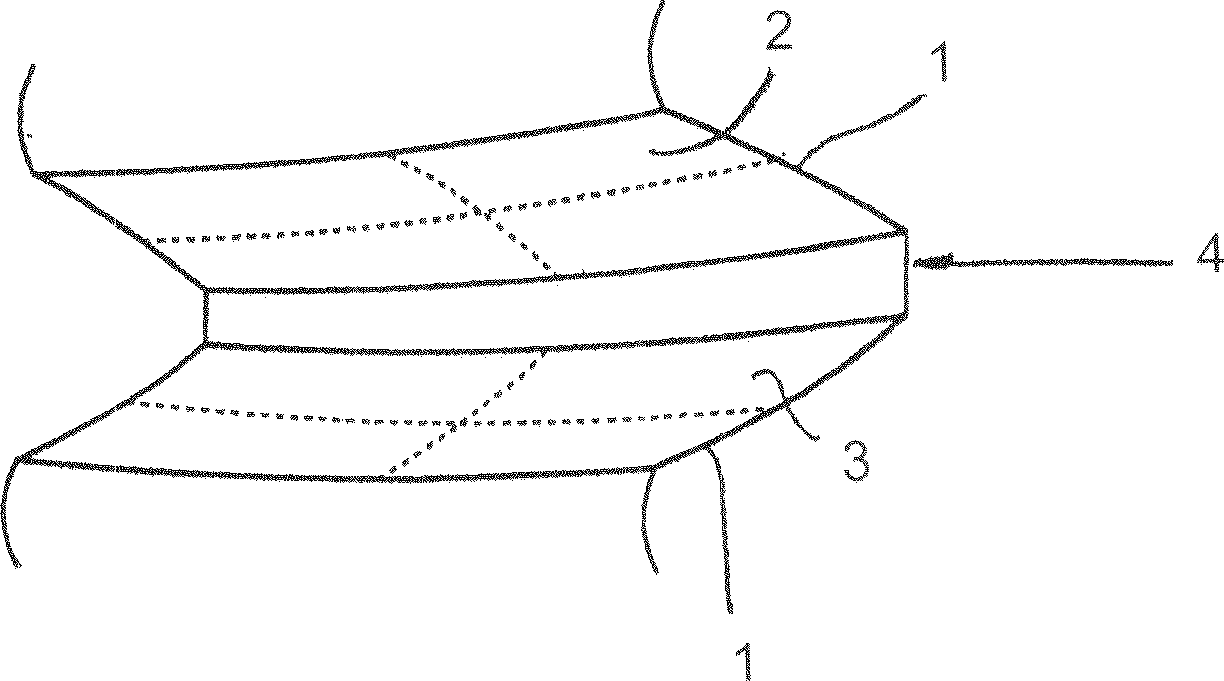

[0013] The device described below is used to chamfer and / or trim the sides of a bevel gear 2, 3 ( image 3 ) and back 4 ( image 3 indistinct) between the edge 1. The device can also be used to machine the area of the edge 1 where the transition of the sides 2, 3 can be rounded towards the top (preferably tip cone angle) and / or the root (top and / or root rounding) .

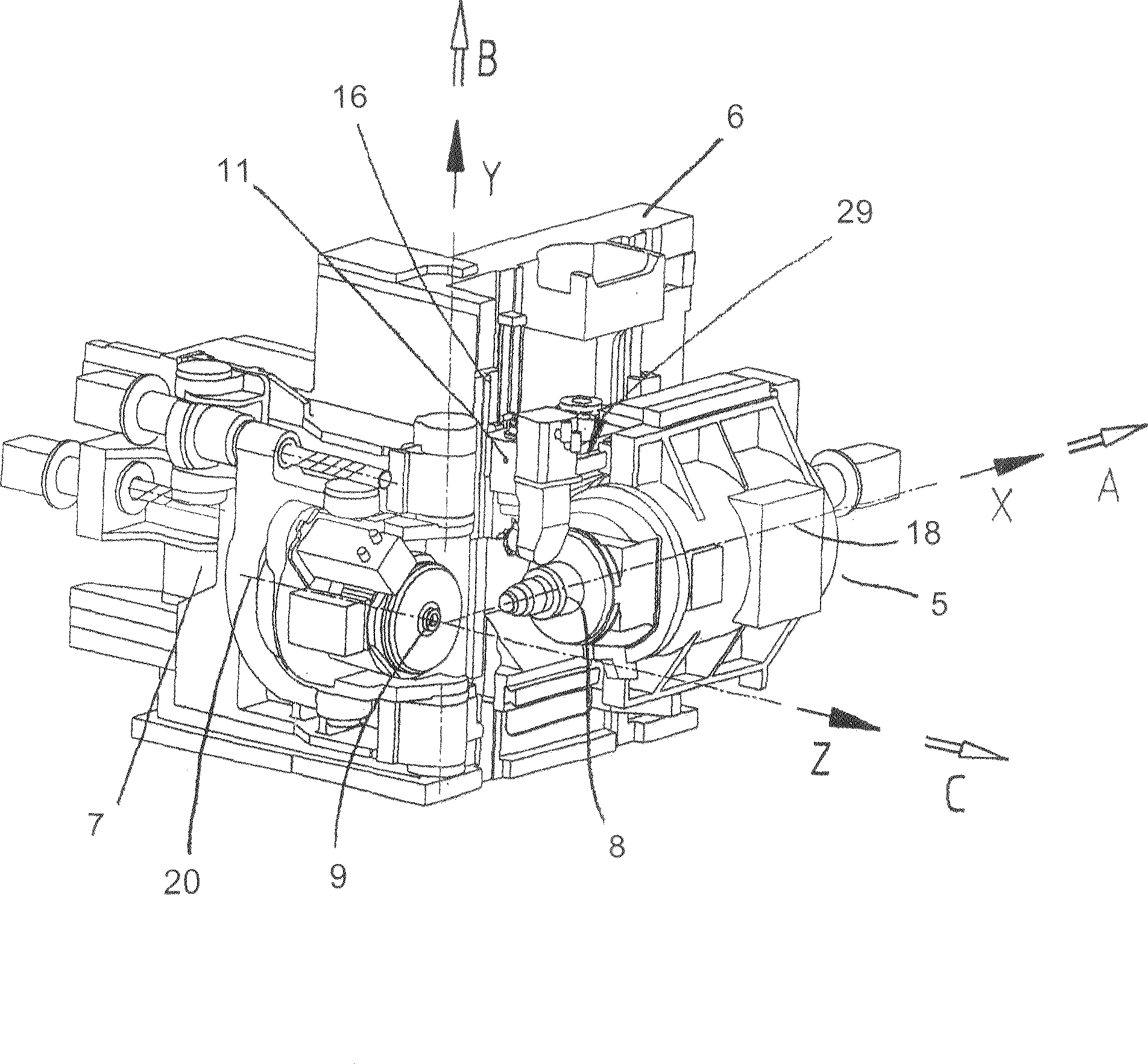

[0014] figure 1 Shown is a machine, such as that shown in U.S. Patent No. 6,712,566 to Stadtfeld et al., having features disposed on the machine, preferably on a stationary column or frame 6 of the machine, for mitering and / or Trimming device. The machine is a bevel gear cutting machine and has a workpiece holder 5 movable in the X direction (direction 18 of the axis of rotation of the workpiece). Furthermore, the workpiece support 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com