Numerical control bevel gear rolling inspection machine

A technology for inspecting machines and bevel gears, which is applied in the direction of machine gear/transmission mechanism testing, power measurement, and measuring devices. It can solve problems such as high labor intensity, inaccurate detection results of gear movement, and difficult observation of detection results, and achieve labor intensity. Accurate and reliable results of small and gear pair motion detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

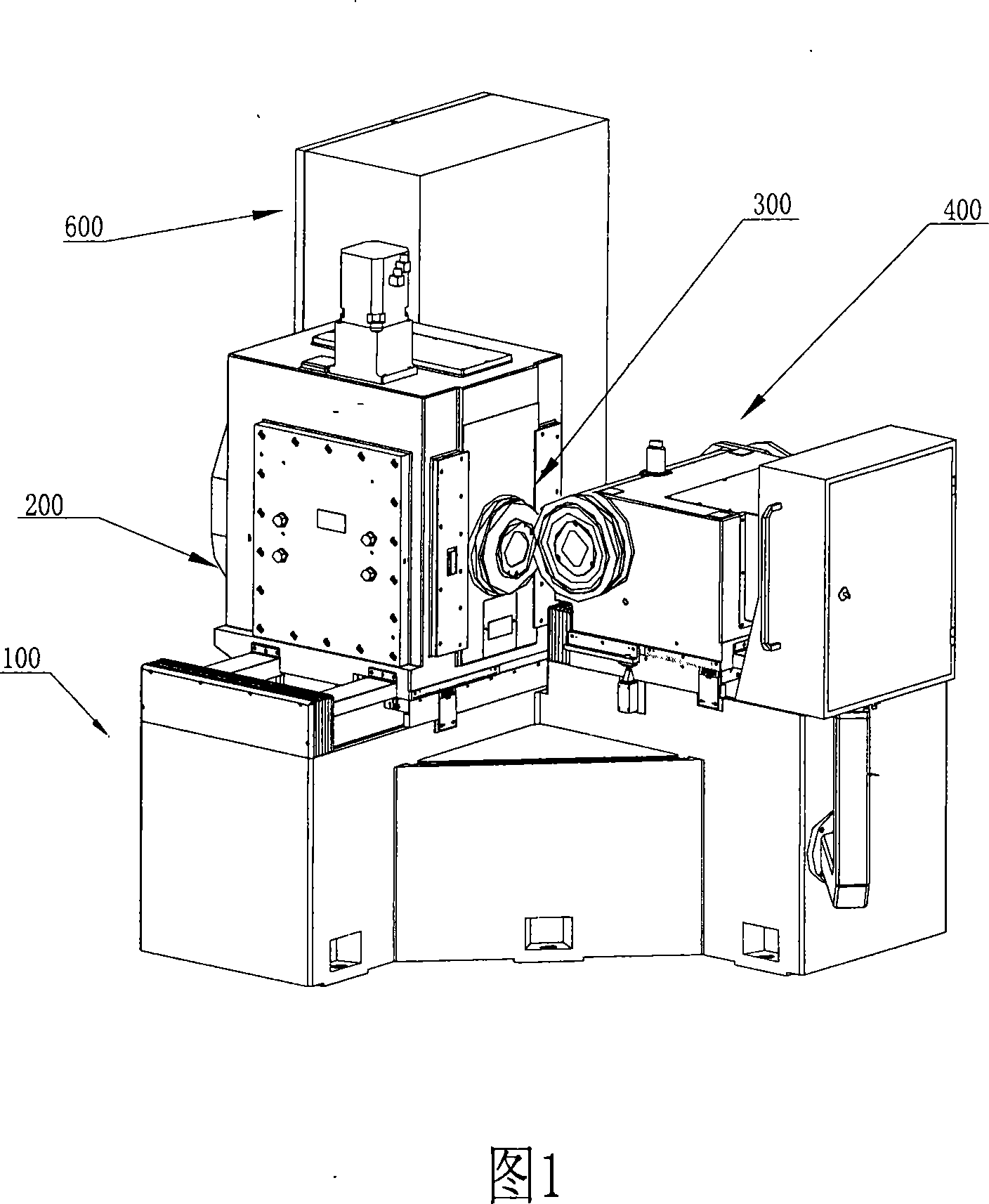

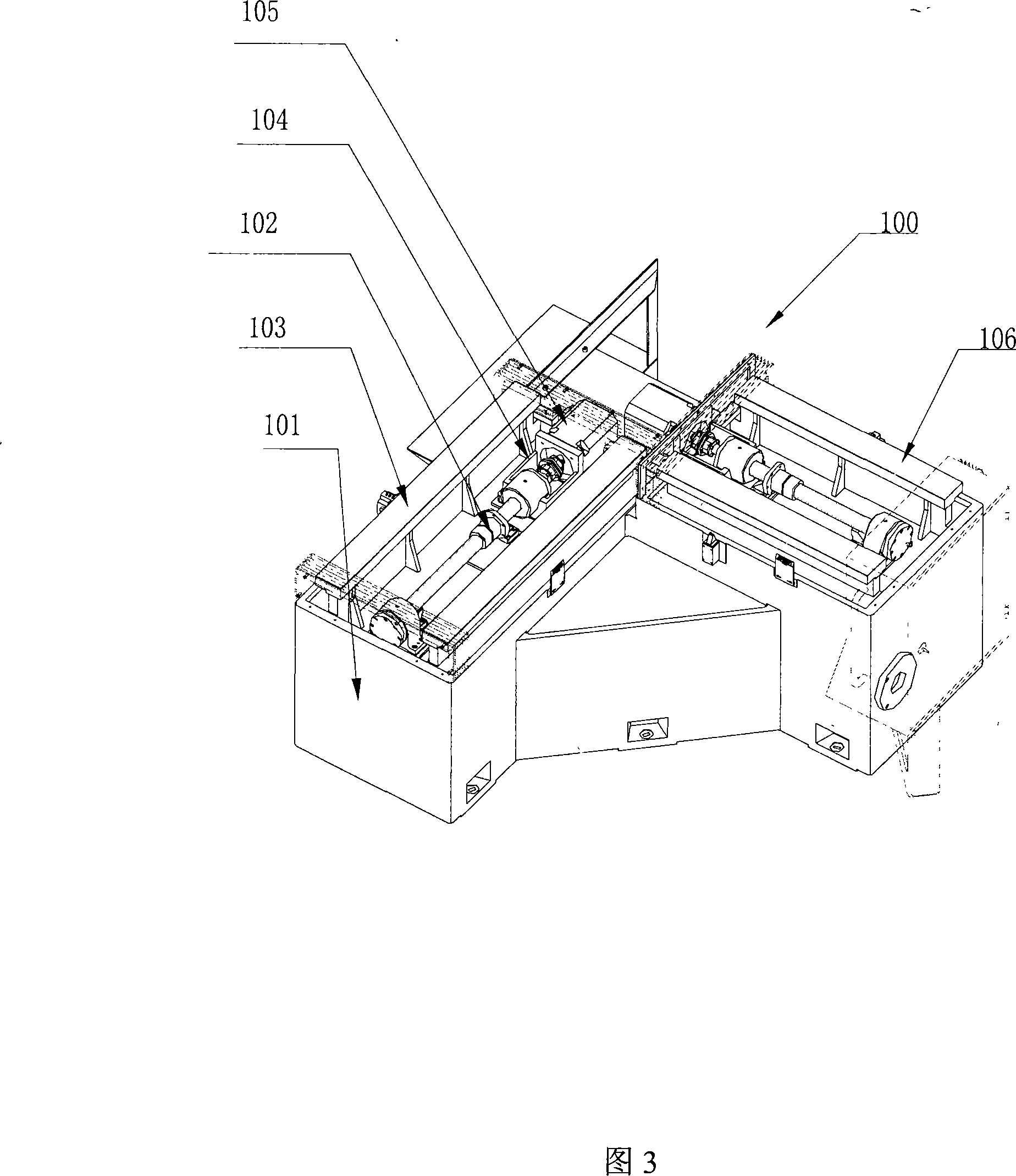

[0044] The present invention provides a numerically controlled bevel gear rolling inspection machine, which includes: a bed part 100 , a column part 200 , a driving box part 400 , a driven box part 300 and an electrical control part 600 . On the bed part 100, a driving guide rail 106 and a driven guide rail 103 which are 90° to each other are arranged respectively. The column part 200 is arranged on the driven guide rail 103 of the bed 101, the active box part 400 is arranged on the active guide rail 106 of the bed 101, between the bottom of the column part 200 and the active box part 400 and the bed 101 respectively An automatic moving mechanism that moves along the driven guide rail 103 and the active guide rail 106 is provided; the driven box part 300 is arranged in the column part 200 and has a mechanism that can automatically move along the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com