Anticorrosive coating for concrete structure reinforcing bars and preparation method thereof

A technology of concrete structure and anti-corrosion coating, applied in anti-corrosion coatings, polyamide coatings, epoxy resin coatings, etc., can solve the influence of the coating on the bonding strength of steel bars and concrete, increase the use cost of steel bars, and affect the steel bars. Anti-corrosion quality and other issues, to achieve excellent adhesion and flexibility, easy operation, cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

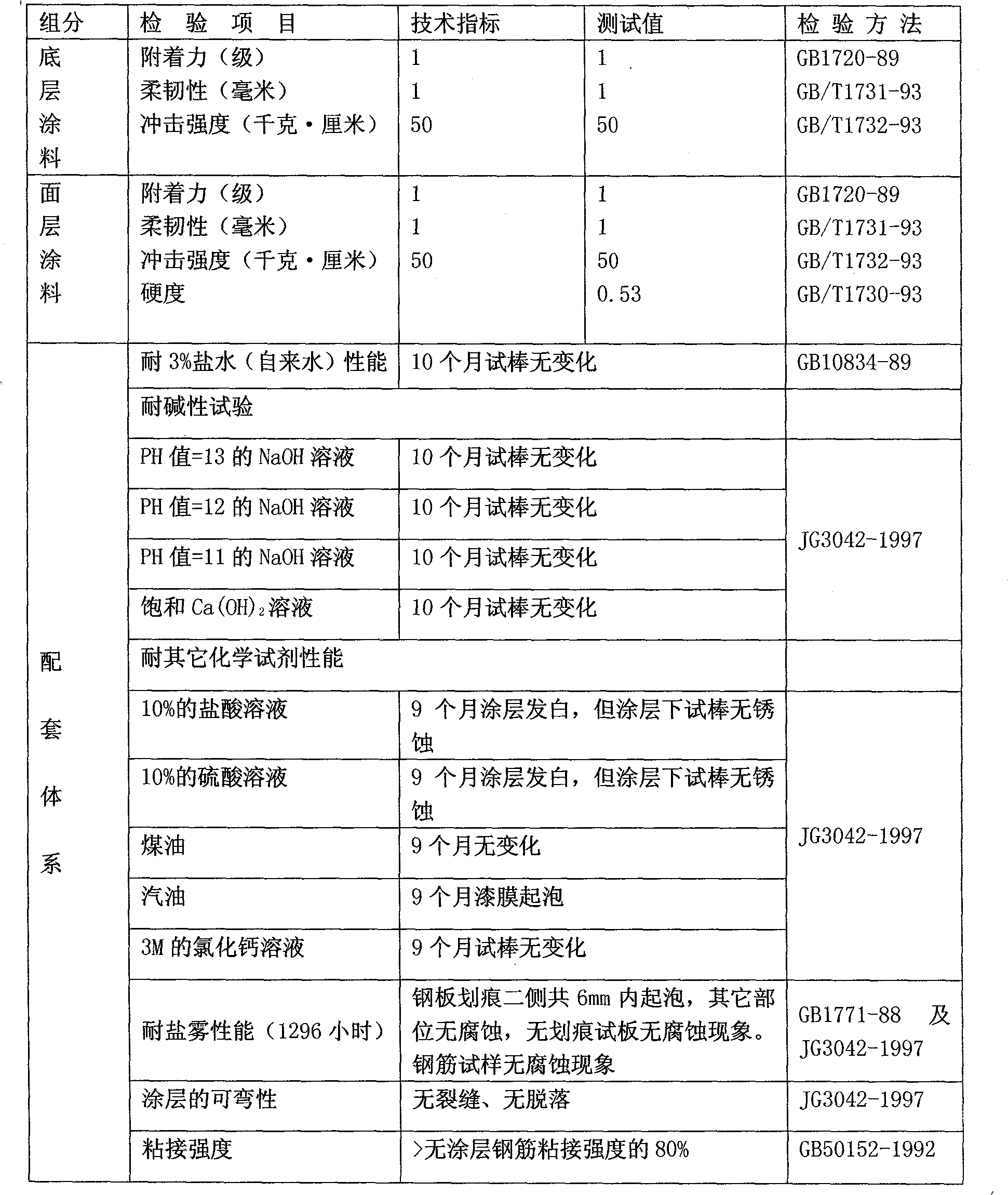

Image

Examples

Embodiment 1

[0032] The technological process and process parameters of the present embodiment are as follows:

[0033] ingredients

[0034] Primer first component formula (parts by weight) is as follows:

[0035] 122 parts of epoxy resin

[0036] 25 parts epoxy resin

[0037] iron red 15 parts

[0038] 10 parts mica iron oxide

[0040] Precipitated barium sulfate 5 parts

[0041] mica 8 parts

[0042] Anti-settling agent 1 part

[0043] Solvent (toluene:n-butanol=4:1) 26 parts

[0044] Primer B component formula (parts by weight): 100 parts of aromatic amine

[0045] The top coat first component formula (parts by weight) is as follows:

[0046] Epoxy resin 1 22 parts

[0047] epoxy resin 2 5 parts

[0048] iron red 10 parts

[0049] 25 glass flakes

[0050] Precipitated barium sulfate 5 parts

[0051] mica 6 parts

[0052] Anti-settling agent 1 part

[0053] Solvent (toluene:n-butanol=4:1) 26 parts

[0054] Topcoat B component formula (parts...

Embodiment 2

[0066] The technological process and process parameters of the present embodiment are as follows:

[0067] ingredients

[0068] Primer first component formula (parts by weight) is as follows:

[0069] Epoxy resin 1 20 parts

[0070] 27 parts epoxy resin

[0071] 10 parts mica iron oxide

[0072] Aluminum tripolyphosphate 8 parts

[0074] Precipitated barium sulfate 7 parts

[0075] mica 9 parts

[0076] Leveling agent 0.5 parts

[0077] Anti-sedimentation agent 0.5 parts

[0078] Solvent (toluene:n-butanol=7:3) 28 parts

[0079] Primer B component formula (parts by weight) is as follows:

[0080] Fatty amine 60 parts

[0081] Aromatic amine 40 parts

[0082] The top coat first component formula (parts by weight) is as follows:

[0083] Epoxy resin 1 20 parts

[0084] epoxy resin 2 7 parts

[0085] iron red 8 servings

[0086] Mica iron oxide 5 parts

[0087] 22 glass flakes

[0088] Precipitated barium sulfate 5 parts

[0089] m...

Embodiment 3

[0104] The technological process and process parameters of the present embodiment are as follows:

[0105] ingredients

[0106] Primer first component formula (parts by weight) is as follows:

[0107] Epoxy resin 1 19 parts

[0108] epoxy resin 2 4 parts

[0109] Mica iron oxide 7 parts

[0110] Aluminum tripolyphosphate 6 parts

[0111] Iron titanium powder 12 parts

[0112] Talc powder 10 parts

[0113] Precipitated barium sulfate 3 parts

[0114] mica 8 parts

[0115] Dispersant 0.5 parts

[0116] Anti-sedimentation agent 0.5 parts

[0117] Solvent (toluene: ethyl ketone: n-butanol = 2: 6: 2) 30 parts

[0118] Primer B component formula (parts by weight): 100 parts of fatty amine

[0119] The top coat first component formula (parts by weight) is as follows:

[0120] Epoxy resin 1 19 parts

[0121] epoxy resin 2 5 parts

[0122] iron red 8 servings

[0123] Mica iron oxide 5 parts

[0124] 24 glass flakes

[0125]Precipitated barium sulfate 5 parts

[0126]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com