Production method of ceria powder polishing size

A production method and technology of cerium oxide, which is applied in the field of multi-layer roasting to produce cerium oxide powder polishing slurry, can solve the problems of weakened mechanical grinding force of cerium oxide, difficulty in exposing the fresh surface of particles, and reduction of lattice defects, etc., to achieve slurry Good suspension and stability, good product quality, and the effect of improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

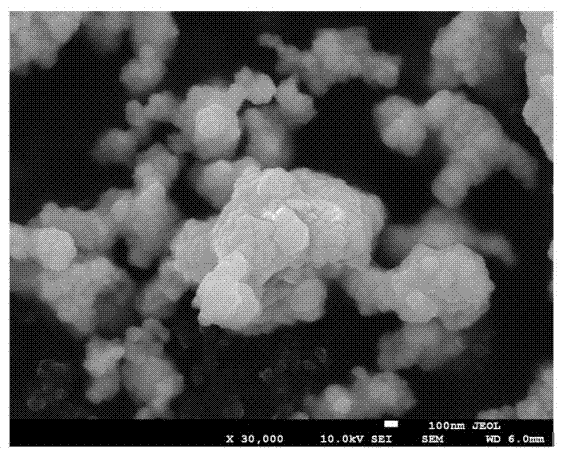

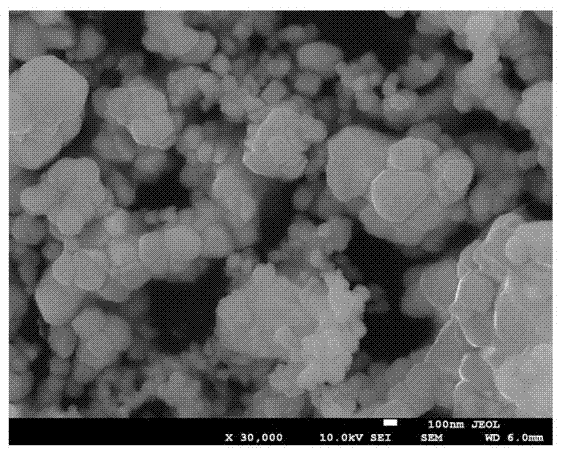

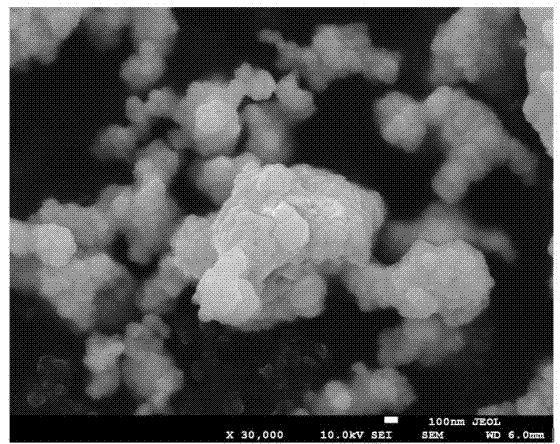

Image

Examples

Embodiment 1

[0018] (1) Add cerium hydroxide into the roasting furnace, gradually raise the temperature from room temperature to 1000°C for roasting, keep at this temperature for 2 hours, and obtain cerium oxide powder;

[0019] When heating up, proceed according to the following heating curve: from room temperature to 160°C over 0.1-0.3h, and keep at 160°C for 0.5h; after 0.2-0.5h to 500°C, keep at 500°C for 1.5h; To 750°C, keep at 750°C for 0.5h; then heat up from 750°C to 1000°C over 0.3-0.8h, keep at 1000°C for 2h; naturally cool from 1000°C to room temperature;

[0020] (2) Mix the obtained cerium oxide powder with nitric acid at a mass ratio of 1:3 to obtain a slurry with a pH of 3-5; put the slurry and metal balls with a diameter of 3-10mm into a ball mill, and grind for 15 hours roughly, and the ball mill speed 50-80r / min; adjust the pH of the slurry after coarse grinding to 3-5, use a metal ball with a diameter of 0.1-2mm to finely grind for 2 hours, and the speed of the ball mill...

Embodiment 2

[0022] (1) Add cerium hydroxide and cerium carbonate into the roasting furnace at a mass ratio of 1:2, gradually raise the temperature to 1000°C for roasting, keep at this temperature for 3 hours, and obtain cerium oxide powder;

[0023] The heating curve is as follows: from room temperature to 160°C for 0.1-0.3h, and hold for 0.5h; for 0.2-0.5h to 500°C, for 1h; After 0.3-0.8h, the temperature is raised to 1000°C, and the temperature is kept for 3h; naturally cooled from 1000°C to room temperature;

[0024] (2) Mix the obtained cerium oxide powder with sulfuric acid at a mass ratio of 1:2 to obtain a slurry with a pH of 3-5; add the slurry and metal balls with a diameter of 3-10 mm into a ball mill, and grind for 20 hours, and then The rotation speed is 50-80r / min; adjust the pH of the slurry after coarse grinding to 3-5, and then use metal balls with a diameter of 0.1-2mm to finely grind for 0.5-3h, the rotation speed of the ball mill is 2000-3000r / min, and finally get ceriu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com