Cerium hydroxide heat stabilizer and preparation method thereof

A technology of cerium hydroxide and heat stabilizer, which is applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., and can solve problems such as complex process, high cost, and poor thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] On the other hand, the preparation method of cerium hydroxide thermal stabilizer of the present invention, it comprises the steps:

[0033] (1) Impurity removal: dissolve cerium nitrate in pure water, heat it to 70-90°C, add 30% hydrogen peroxide, adjust the pH value to 4.0-4.5 with ammonia water, and vacuum filter to obtain a clear and transparent cerium nitrate solution;

[0034] (2) Synthesis of cerium hydroxide: Add the above cerium nitrate solution to 30% hydrogen peroxide, adjust the pH value to 8.5-9 with ammonia water, heat to 70-90°C for 1.5-2h, and filter through plate to obtain cerium hydroxide filter cake;

[0035] (3) Preparation of heat stabilizer: drying and pulverizing the obtained cerium hydroxide filter cake to obtain the cerium hydroxide heat stabilizer.

[0036] In the present invention, in step (1), the cerium nitrate is dissolved in pure water, and the mass of cerium nitrate accounts for 30-40% of the sum of the mass of cerium nitrate and water; t...

Embodiment 1

[0040] (1) Impurity removal: 300kg cerium nitrate (CeO 2 / TREO≥99.9%) was dissolved in 700kg of pure water, heated to 70°C, added 30% hydrogen peroxide, and adjusted to pH 4.0 with 10% ammonia water. After vacuum filtration, a clear and transparent cerium nitrate solution was obtained.

[0041] (2) Synthesis of cerium hydroxide: Add the above cerium nitrate solution to 90 kg of 30% hydrogen peroxide, adjust the pH value to 8.5 with 10% ammonia water, heat to 70°C for 2 hours, and filter through a plate to obtain a cerium hydroxide filter cake.

[0042] (3) Preparation of heat stabilizer: the obtained cerium hydroxide filter cake was dried at 150° C. for 30 h, and then pulverized by air flow to obtain the cerium hydroxide heat stabilizer.

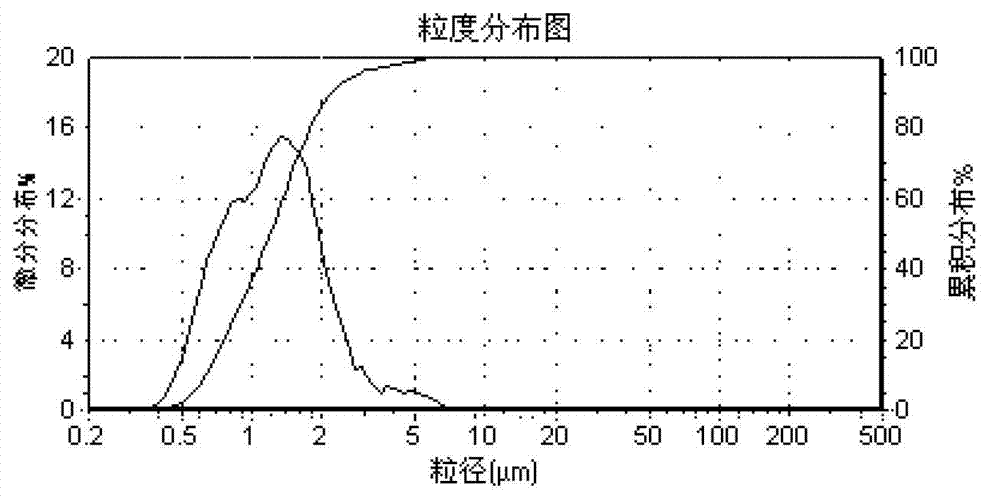

[0043] In the prepared cerium hydroxide heat stabilizer, the total amount of rare earth is 95%, and the content of cerium oxide (CeO 2 / TREO) is 99.98%, loss on ignition is 5%, average particle size D 50 is 1.19 μm. (see figure 1 )

Embodiment 2

[0045] (1) Impurity removal: 400kg cerium nitrate (CeO 2 / TREO≥99.9%) was dissolved in 600kg of pure water, heated to 90°C, added 30% hydrogen peroxide, and adjusted to pH 4.5 with 15% ammonia water. After vacuum filtration, a clear and transparent cerium nitrate solution was obtained.

[0046] (2) Synthesis of cerium hydroxide: Add the above cerium nitrate solution to 120kg of 30% hydrogen peroxide, adjust the pH value to 9 with 15% ammonia water, heat to 90°C for 1.5h, and filter through a plate to obtain a cerium hydroxide filter cake.

[0047] (3) Preparation of heat stabilizer: the obtained cerium hydroxide filter cake was dried at 180° C. for 20 h, and then pulverized by air flow to obtain the cerium hydroxide heat stabilizer.

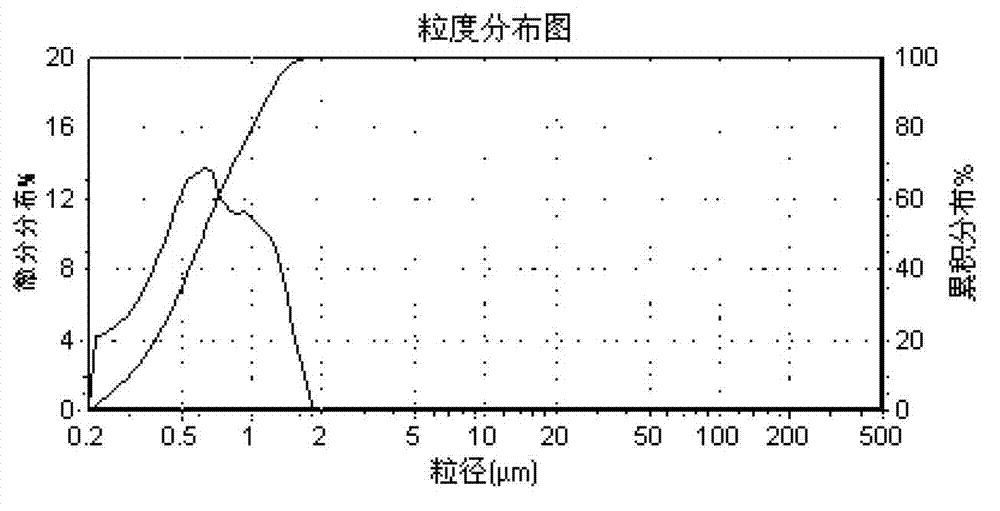

[0048] In the prepared cerium hydroxide heat stabilizer, the total amount of rare earth is 95%, and the content of cerium oxide (CeO 2 / TREO) is 99.95%, loss on ignition is 5.4%, average particle size D 50 0.5 μm. (see figure 2 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com