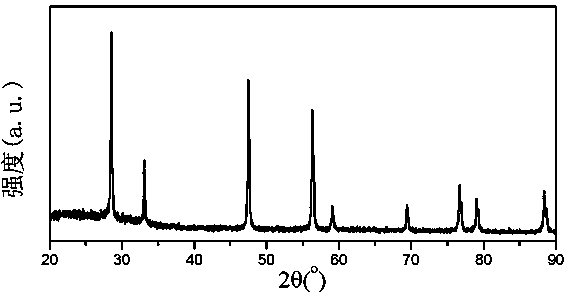

Preparation method of cubic Nb-CeO2 material as well as product and application thereof

A technology of cube and catalytic material, which is applied in catalyst activation/preparation, combustion method, catalyst carrier, etc., can solve the problems of inconvenient operation, expensive niobium source, difficult to have morphology and structure of niobium-ceria composite oxide, etc. The effect of doping, high niobium content, simple and novel method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A cubic Nb-CeO 2 The preparation method of the material is to disperse the sodium cerium hydroxide prepared by the hydrothermal method in the niobium oxalate solution, and after the solvent is completely evaporated, it is placed in a muffle furnace and roasted together to obtain Nb-CeO 2 Composite oxides, according to the following steps:

[0036]Weigh 4.34g of cerium nitrate hexahydrate into a 50 mL beaker, add 20 mL of deionized water, stir and dissolve to obtain solution A; weigh 48g of sodium hydroxide into a 100 mL beaker, add 50 mL of deionized water, heat and stir to dissolve Solution B is obtained. Under vigorous stirring, solution A was added dropwise to solution B to form milky C. The milky C was transferred to a 100mL hydrothermal reactor, and the hydrothermal reactor was placed in an oven at 120°C for 36h. After the reaction was completed, the precipitate D was filtered, washed several times, and dried to obtain powder E. Weigh 5.38g of niobium oxalate a...

Embodiment 2

[0038] A cubic Nb-CeO 2 The preparation method of material is similar to embodiment 1, as follows:

[0039] Weigh 4.34g of cerium nitrate hexahydrate into a 50 mL beaker, add 20 mL of deionized water, stir and dissolve to obtain solution A; weigh 48g of sodium hydroxide into a 100 mL beaker, add 50 mL of deionized water, heat and stir to dissolve Solution B is obtained. Under vigorous stirring, solution A was added dropwise to solution B to form milky C. The milky C was transferred to a 100mL hydrothermal reactor, and the hydrothermal reactor was placed in an oven at 150°C for 48 hours. After the reaction was completed, the precipitate D was filtered, washed several times, and dried to obtain powder E. Weigh 5.38g of niobium oxalate and place it in a 500mL beaker, add 200mL of deionized water, stir to dissolve, then add water to a 1000mL volumetric flask to obtain solution F, take 25mL of solution F, and under strong stirring, mix 1.5g of powder E Add to solution F. Heat ...

Embodiment 3

[0041] A cubic Nb-CeO 2 The preparation method of material is similar to embodiment 1, as follows:

[0042] Weigh 4.34g of cerium nitrate hexahydrate into a 50 mL beaker, add 20 mL of deionized water, stir and dissolve to obtain solution A; weigh 48g of sodium hydroxide into a 100 mL beaker, add 50 mL of deionized water, heat and stir to dissolve Solution B is obtained. Under vigorous stirring, solution A was added dropwise to solution B to form milky C. The milky C was transferred to a 100mL hydrothermal reactor, and the hydrothermal reactor was placed in an oven at 130°C for 48 h. After the reaction was completed, the precipitate D was filtered, washed several times, and dried to obtain powder E. Weigh 5.38g of niobium oxalate and place it in a 500mL beaker, add 200mL of deionized water, stir to dissolve, then add water to a 1000mL volumetric flask to obtain solution F, take 25mL of solution F, and under strong stirring, mix 1.5g of powder E Add to solution F. Heat in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com