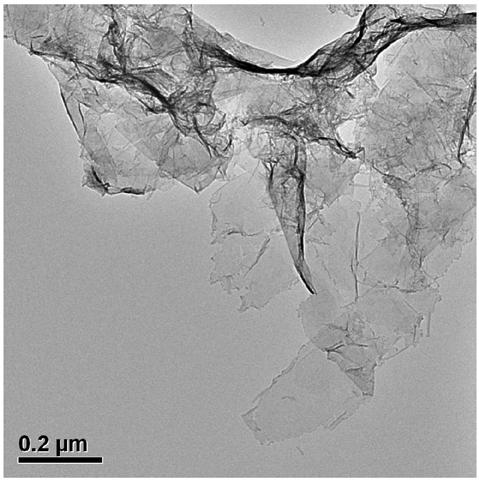

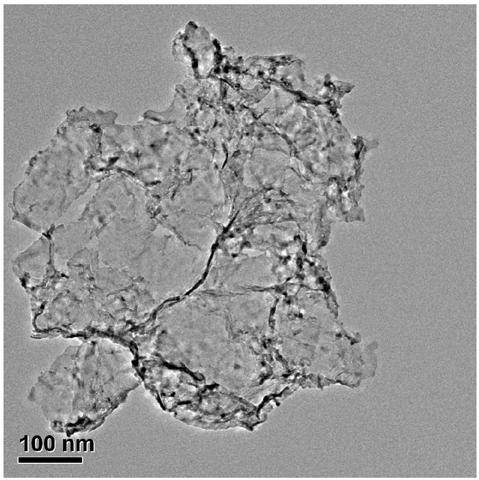

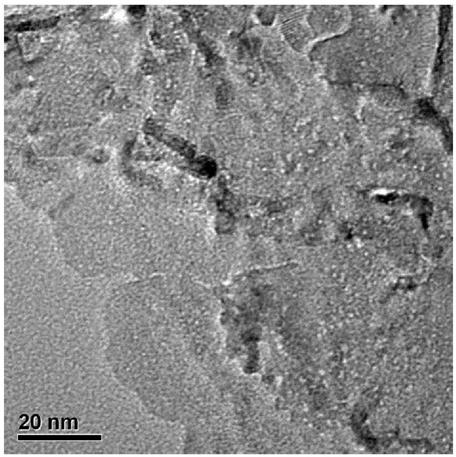

Cerium dioxide nanosheet as well as preparation method and application thereof

A technology of ceria and nanosheets, which is applied in the field of ceria nanosheets and its preparation, can solve the problems of high environmental hazards, limited applications, and obstacles to the interaction between substrate molecules and nanoparticles, and achieve high specific surface area and catalytic performance. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This embodiment provides a method for preparing a ceria nanocomposite material, the preparation method comprising the following steps:

[0073] (1) 20 DEG C under the protection of nitrogen, the molar concentration of the hydroxide ion is that the sodium hydroxide aqueous solution of 3mol / L is added dropwise in the cerium nitrate aqueous solution that the molar concentration of cerium nitrate is 0.05mol / L, the said hydroxide The molar ratio of root ion and described cerium nitrate is 18:1, and the speed of described dropping is 14mL / h, stirs cerium nitrate aqueous solution in precipitation process, and the time of described stirring is 9h, and the speed of described stirring is 1000r / h min, wash the precipitate to neutrality, and obtain the cerium hydroxide nanosheet precursor;

[0074] (2) Freeze-drying step (1) obtained cerium hydroxide nanosheet precursor, under the condition of 600 ℃, the cerium hydroxide nanosheet precursor after freeze-drying is roasted, and the t...

Embodiment 2

[0079] This embodiment provides a method for preparing a ceria nanocomposite material, the preparation method comprising the following steps:

[0080] (1) 25 DEG C under argon protection, the molar concentration of hydroxide ion is that the sodium hydroxide aqueous solution of 4mol / L is added dropwise in the cerium nitrate aqueous solution that the molar concentration of cerium nitrate is 0.06mol / L, the hydrogen The mol ratio of oxygen ion and described cerium nitrate is 12:1, and the speed of described dropping is 16mL / h, stirs cerium nitrate aqueous solution in precipitation process, and the time of described stirring is 12h, and the speed of described stirring is 1200r / min, wash and precipitate to neutrality, and obtain the precursor of cerium hydroxide nanosheet;

[0081] (2) Freeze-drying step (1) obtained cerium hydroxide nanosheet precursor, under the condition of 420 ℃, the cerium hydroxide nanosheet precursor after freeze-drying is roasted, and the time of described ...

Embodiment 3

[0086] This embodiment provides a method for preparing a ceria nanocomposite material, the preparation method comprising the following steps:

[0087] (1) 15 DEG C under the protection of helium, the molar concentration of hydroxide ion is 2mol / L potassium hydroxide aqueous solution is added dropwise in the cerium nitrate aqueous solution that the molar concentration of cerium nitrate is 0.02mol / L, the hydrogen The mol ratio of oxygen ion and described cerium nitrate is 10:1, and the speed of described dropping is 12mL / h, stirs cerium nitrate aqueous solution in precipitation process, and the time of described stirring is 6h, and the speed of described stirring is 800r / min, wash and precipitate to neutrality, and obtain the precursor of cerium hydroxide nanosheet;

[0088] (2) Freeze-drying step (1) obtained cerium hydroxide nanosheet precursor, under the condition of 400 ℃, the cerium hydroxide nanosheet precursor after freeze-drying is roasted, and the time of described roa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com