Preparation of single crystalline cerium oxide powder

A cerium oxide, cerium hydroxide technology, applied in chemical instruments and methods, cerium oxide/cerium hydroxide, lanthanide oxide/hydroxide, etc., can solve problems such as energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0042] The method of hydrothermally synthesizing ceramic powder includes mixing and dispersing of raw materials, performing hydrothermal reaction in a suitable reactor, and cleaning and drying.

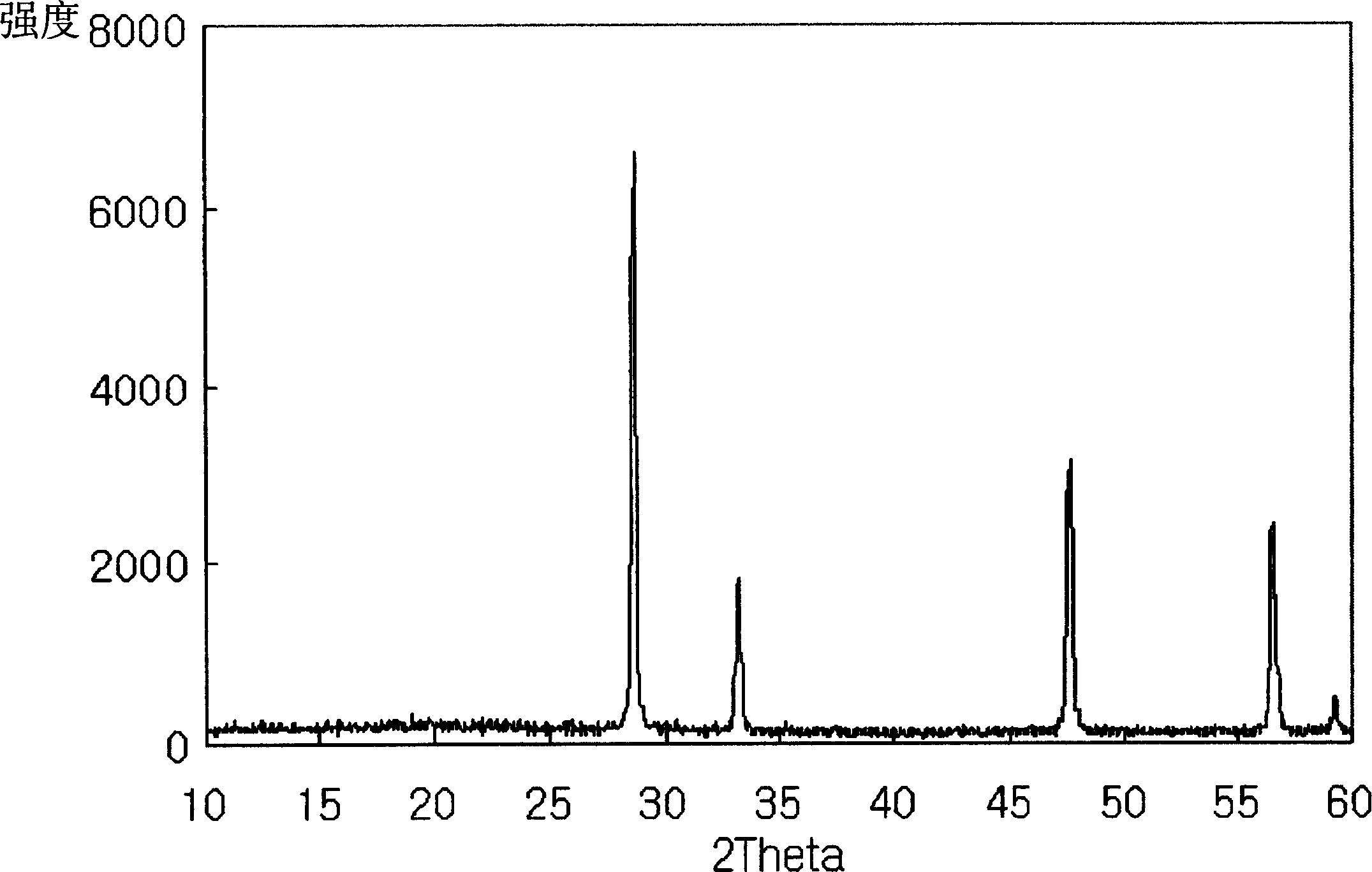

[0043] The reaction equipment used in the present invention is a 100 ml, 2 liter and 2 gallon autoclave and is operated using their respective force or mechanical force. Hot distilled water and alcohol were used to wash the reaction product, and after washing and filtering, the reaction product was dried in a drying oven at 100° C. for 5 hours or more. The dried powder was observed with an XRD (X-ray diffraction) analysis device to determine crystallinity and degree of crystallinity, and the dry powder was observed through an electron microscope to determine the shape and size of particles. figure 1 It is the result of XRD analysis of cerium oxide prepared according to the method of the present invention. exist figure 1 In , the ordinate represents the X-ray intensity, and the absci...

example 1

[0048] 0.04 moles of cerium nitrate (produced by Aldrich, with a purity of 99%) were dissolved in a mixed solution of 200 milliliters of distilled water and 100 milliliters of ethylene glycol, and then 160 milliliters of 0.5 M NaOH aqueous solution was added to precipitate cerium hydroxide at 50° C. . The precipitated hydroxide was washed with distilled water, and then dispersed in distilled water so that the total solution volume became 100 ml.

[0049] Take 10 milliliters of the precipitated hydroxide solution and disperse it in 10 milliliters of distilled water, carry out hydrothermal reaction for 12 hours at a stirring speed of 200 rpm and a temperature of 230° C. Therefore, the average particle size is spherical or boat-shaped cerium oxide of 80 nanometers is synthesized. SEM photographs of cerium oxide as image 3 shown. The magnification of the SEM photograph is 100,000 times, and the length of the calibration line shown represents 100 nanometers.

example 2

[0051] 0.06 mole of cerium nitrate (produced by Aldrich, purity 99%) was dissolved in a mixed solution of 100 ml of distilled water and 200 ml of butanol, and then 200 ml of 0.5 M KOH aqueous solution was added to precipitate cerium hydroxide at 50° C. The precipitated hydroxide was washed with distilled water, and then dispersed in distilled water so that the volume of the solution became 100 ml.

[0052] Take 20 ml of the precipitated hydroxide solution and disperse it in 10 ml of distilled water, and carry out a hydrothermal reaction for 12 hours at a stirring speed of 300 rpm and a temperature of 230° C. Spherical or boat-shaped cerium oxide with an average particle size of 30 to 80 nm was synthesized. SEM photographs of cerium oxide as Figure 4 shown. The magnification of the SEM photograph is 100,000 times, and the length of the calibration line shown represents 100 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com