Hydro-thermal preparation method for cerium oxide and application of cerium oxide in chemical-mechanical polishing

A technology of cerium oxide and cerium hydroxide, applied in the field of CMP polishing application, can solve the problem of less cerium oxide nanomaterials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

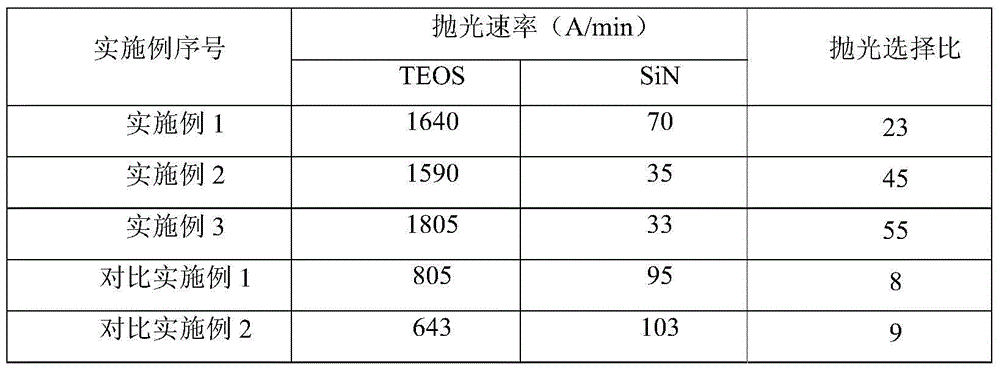

Embodiment 1

[0019] At room temperature, prepare 0.05M cerium nitrate, 0.05MH 2 o 2 and 0.05M ammonium hydroxide aqueous solution, slowly add the ammonium hydroxide aqueous solution to the cerium nitrate aqueous solution, the precipitation reaction temperature is 30 ° C, when the pH value of the mixed precipitation slurry reaches 7.0, stop adding the precipitant ammonium hydroxide; the configured h 2 o 2 Added to the above precipitation slurry, H 2 o 2 The molar ratio to the cerium ion in the reaction system is 1.5 / 1.0, and keep stirring for 30 minutes after the addition is completed; after the obtained precipitated slurry is suction filtered and washed 3 times, the pH value of the mixed system is adjusted to 2.0 with nitric acid, and heated at 120°C The hydrothermal crystallization reaction was carried out for 10 hours, and the cerium oxide dispersion slurry was obtained after cooling, which can be further applied to the cerium oxide abrasive for STI polishing.

Embodiment 2

[0021] At room temperature, prepare 1.0M cerium nitrate, 1.0MH 2 o 2 and 1.0M sodium hydroxide aqueous solution, slowly add the sodium hydroxide aqueous solution to the cerium nitrate solution, the precipitation reaction temperature is 90 ° C, when the pH value of the mixed precipitation slurry reaches 10.0, stop adding the precipitant sodium hydroxide; the configured h 2 o 2 Added to the above precipitation slurry, H 2 o 2 The molar ratio to the cerium ion in the reaction system is 2.0 / 1.0, and keep stirring for 30 minutes after the addition is completed; after the obtained precipitated slurry is suction filtered and washed 3 times, the pH value of the mixed system is adjusted to 2.0 with nitric acid, and heated at 180°C The hydrothermal crystallization reaction was carried out for 8.0 hours, and the cerium oxide dispersion slurry was obtained after cooling, which can be further applied to the cerium oxide abrasive for STI polishing.

Embodiment 3

[0023] At room temperature, prepare 0.5M cerium nitrate, 0.5MAPS and 0.5MTMAH aqueous solutions respectively, slowly add the TMAH aqueous solution to the cerium nitrate solution, the precipitation reaction temperature is 80°C, when the pH value of the mixed precipitation slurry reaches 8.5, stop adding the precipitation Add the prepared APS to the above precipitation slurry, the molar ratio of APS to cerium ions in the reaction system is 2.0 / 1.0, and keep stirring for 30 minutes after the addition; filter and wash the obtained precipitation slurry 3 times Finally, adjust the pH value of the mixed system to 4.0 with nitric acid, and conduct a hydrothermal crystallization reaction at 200°C for 0.5 hours. After cooling, a cerium oxide dispersion slurry can be obtained, which can be further applied to cerium oxide abrasives for STI polishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com