Method recovering rare earth from precise instrument waste glass materials

A glass waste and precision instrument technology, applied in the field of glass instrument waste treatment, can solve the problems of resource waste, environmental pollution, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

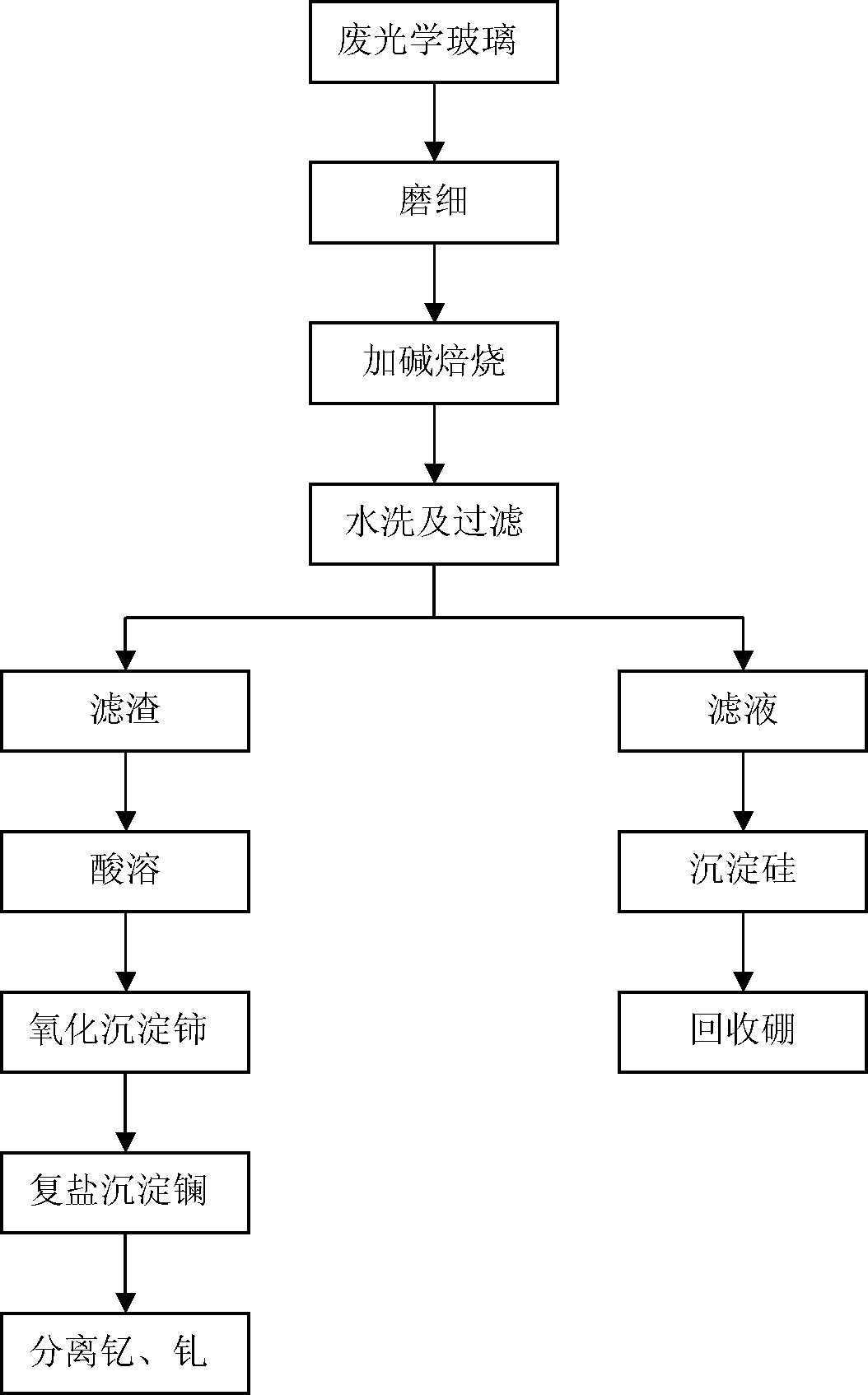

Method used

Image

Examples

example 1

[0048] The method of the present invention is described below with a specific process for treating waste precision instrument glass, but it is not intended as a limitation to the protection scope of the present invention.

[0049] First, take 100g of waste precision instrument glass and grind it finely with a ball mill. The final average particle size of waste glass is 0.05mm.

[0050] Mix the above-mentioned glass powder with sodium hydroxide solution with a concentration of 8 mol / l, the mass ratio of sodium hydroxide to glass powder is 1:2.2, and then bake at 400°C for 3 hours.

[0051] The roasted material was washed with hot water at 75°C, with a solid-to-liquid ratio of 1:4.5, stirred and washed for 3 hours, and filtered. The filtrate contains silicate, borate, etc., and the filter residue contains rare earth elements.

[0052] The filtrate is stirred at 90°C and adjusted to pH 4.5 with 2.5 mol / l sulfuric acid to precipitate silicon. The supernatant is concentrated and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com