Method for preparing supported copper oxide catalyst by using cerium oxide as carrier

A technology of copper oxide and cerium oxide, which is applied in the field of preparation of supported copper oxide catalysts, can solve the problems of narrow window temperature, reduce the complete conversion temperature of carbon monoxide, expand the window temperature, and high operating temperature, and achieve wide window temperature and increase the coordination structure , The effect of improving redox performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

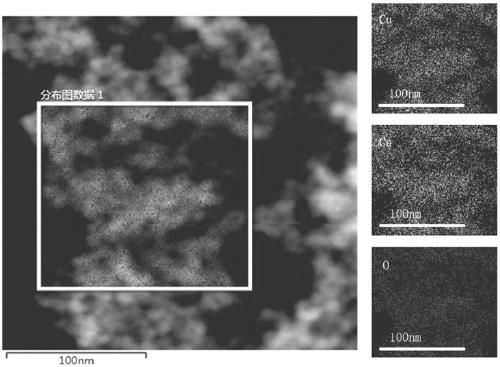

[0021] (1) Weigh 0.5g of copper nitrate solid, add 50ml of deionized water, then add 10ml of cerium nitrate solution with a concentration of 1.16mol / L, stir evenly, keep the speed at a low speed to ensure even stirring, and keep the temperature at 25°C . Weigh 10.56g of sodium hydroxide solid, pour it into it at one time, and the temperature rises from 25°C to 50°C. The solution turned green first and then yellow, and a precipitate formed. Stir for 5min.

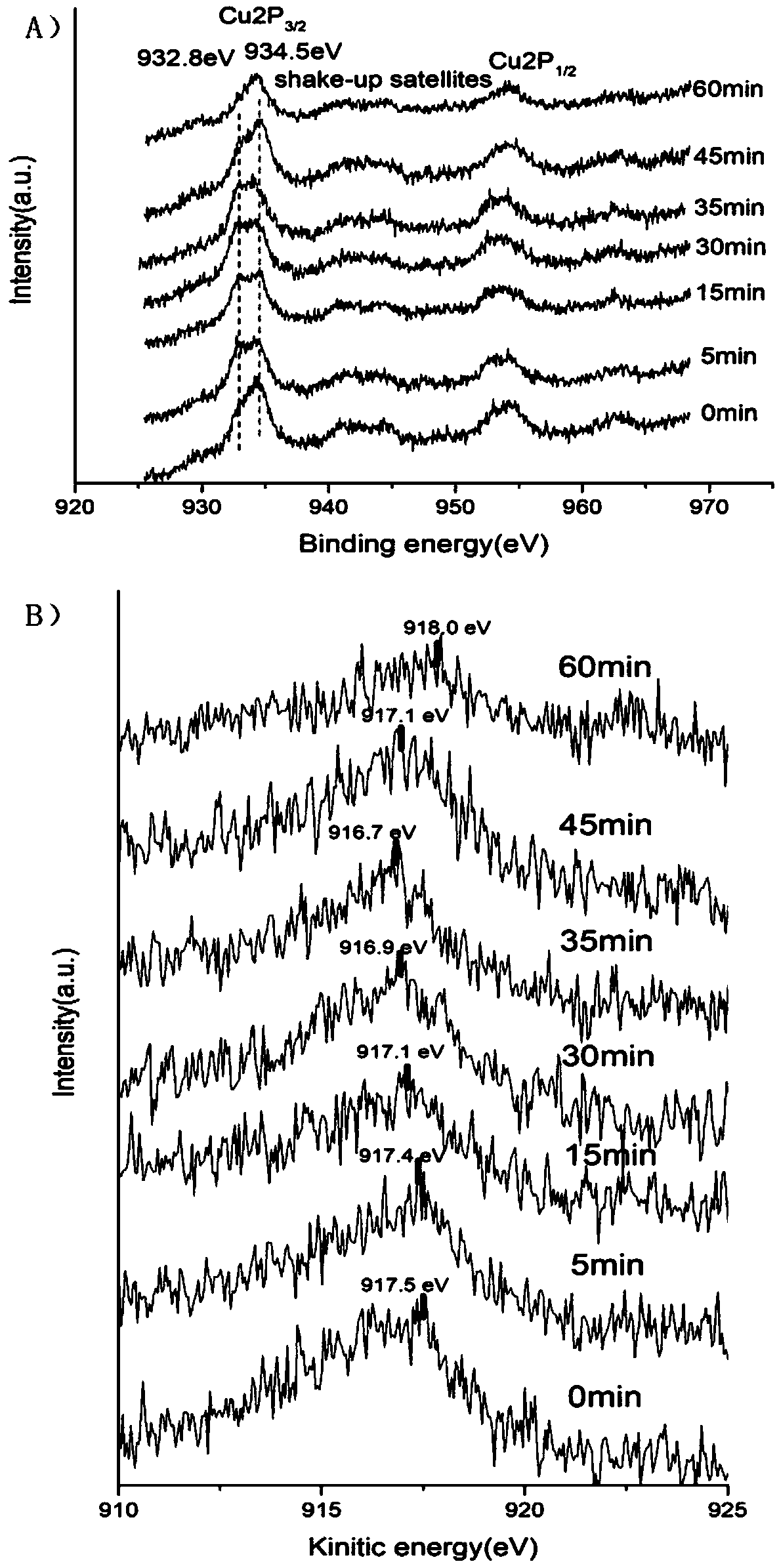

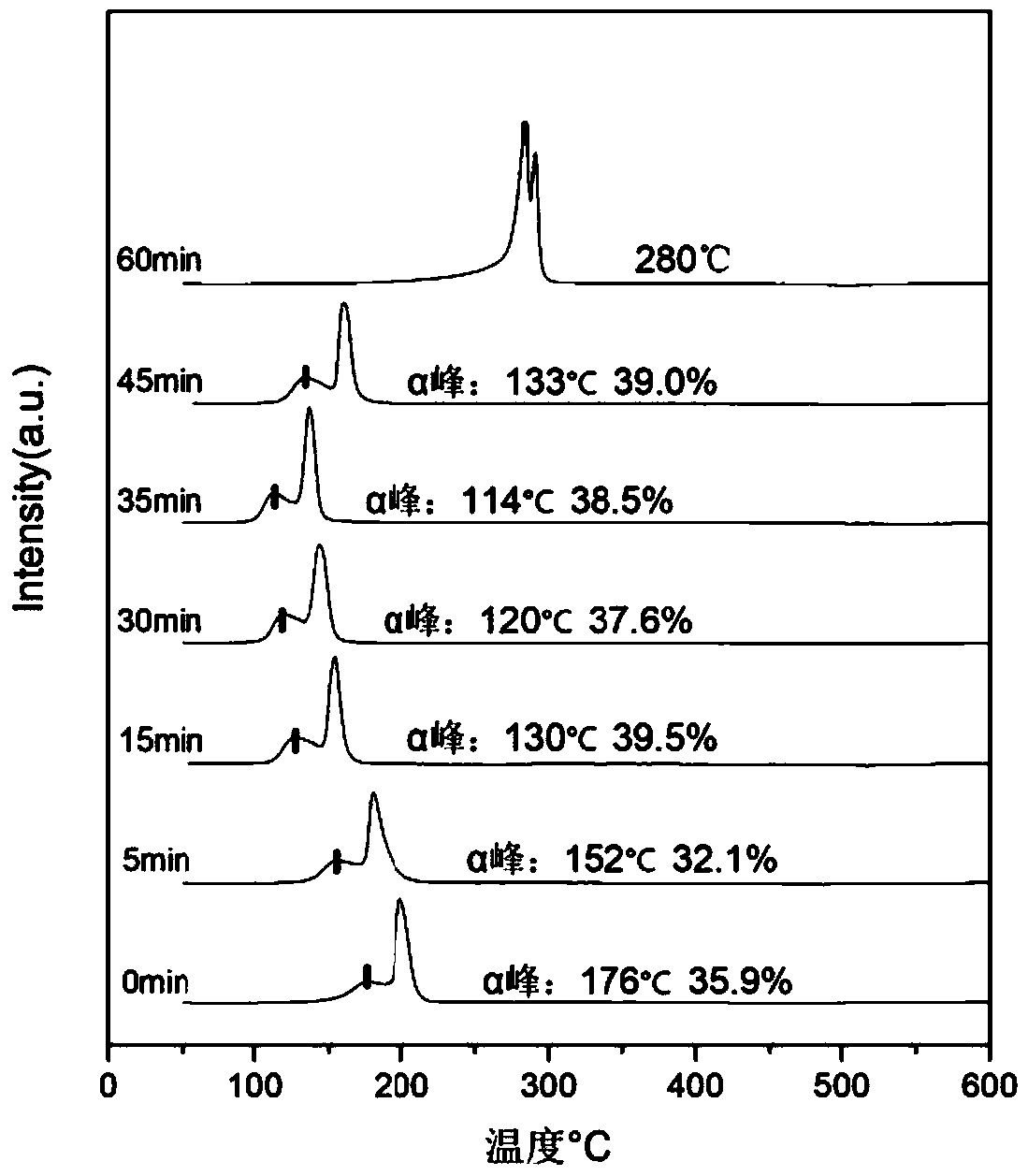

[0022] (2) the suspension prepared in step 1 is subjected to ultrasonic treatment at 40KHZ, frequency and power of 250W, and samples are taken at 0min, 5min, 15min, 30min, 35min, 45min, and 60min;

[0023] (3) The 7 samples after ultrasonic treatment in step 2 were processed as follows: transfer to -2°C low-temperature water bath and stir for 30 minutes, then centrifugally wash with deionized water 8 times, and the pH of the washing solution was less than 9. The washed solid was dried in a freeze-drying oven for 24 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com