Cerium phosphate coated ternary cathode material, preparation method thereof and lithium ion battery

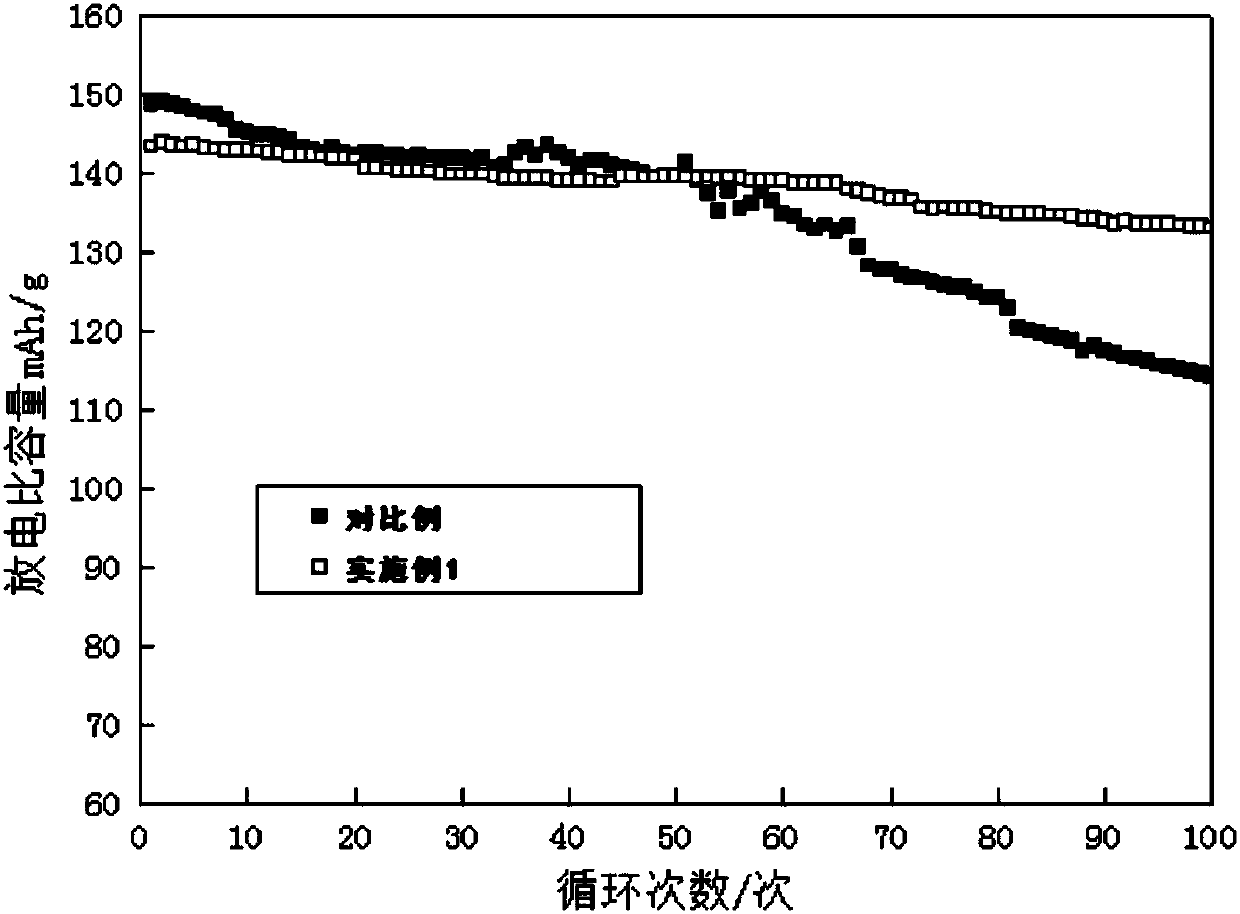

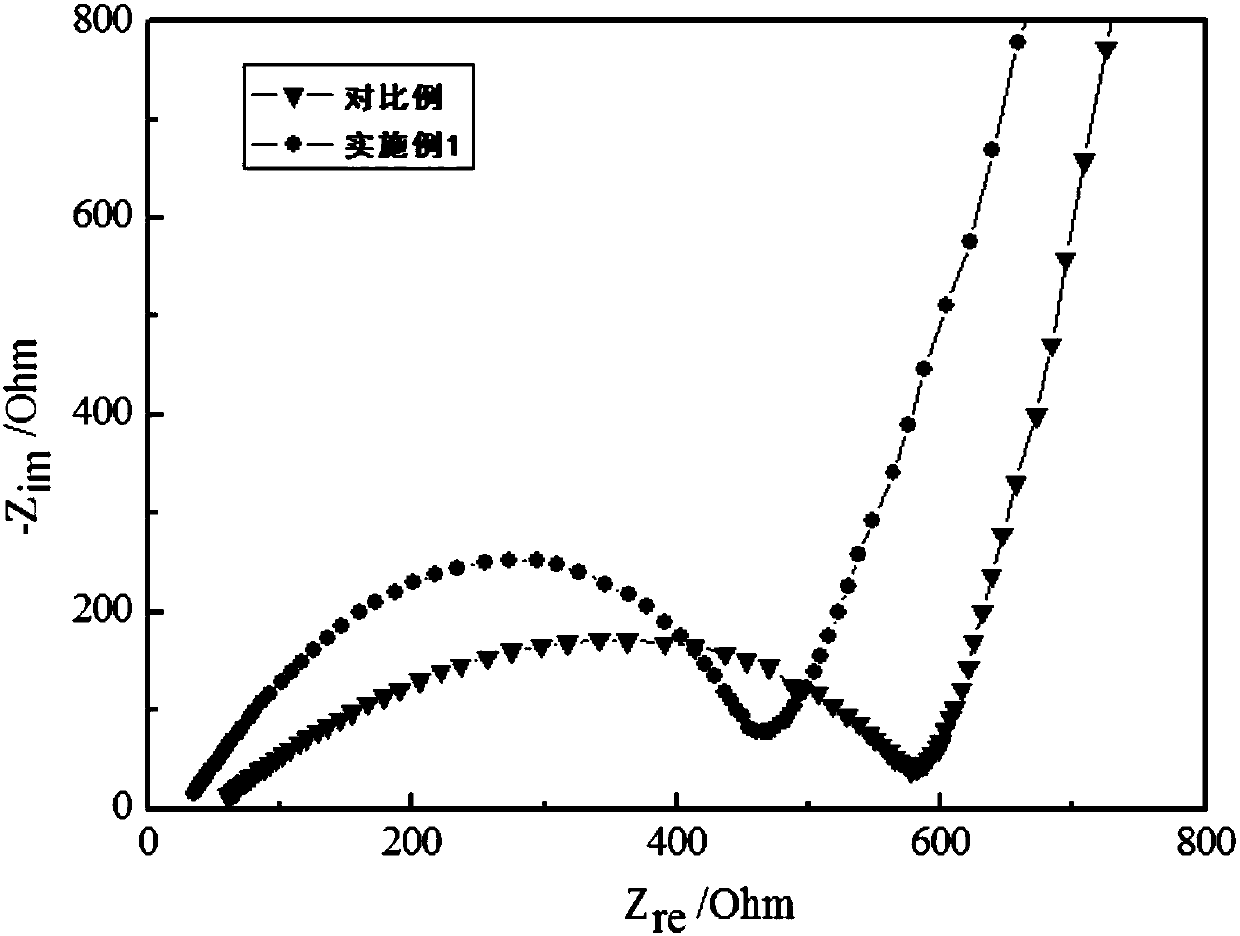

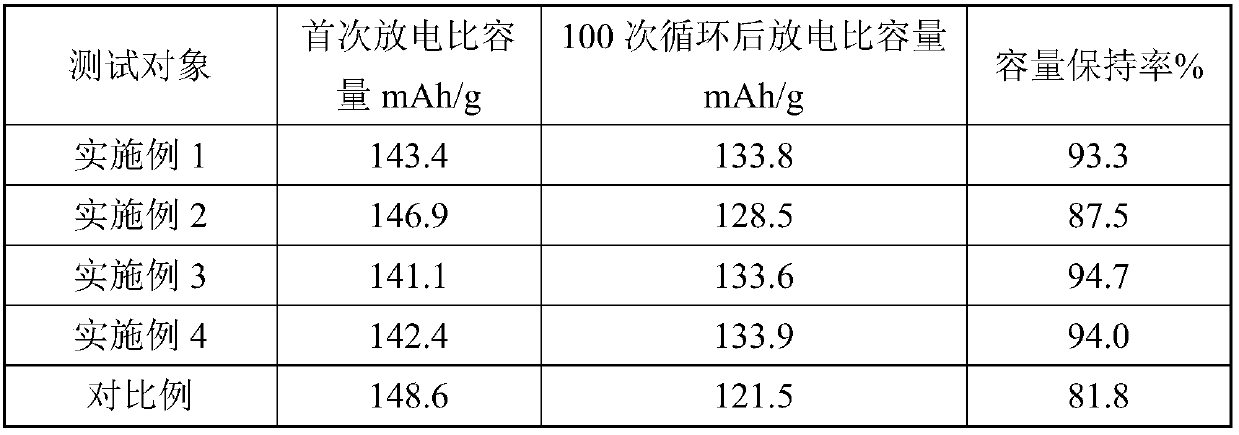

A positive electrode material and ternary material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle performance and rate performance, achieve good cycle performance and rate performance, reduce side reactions, and uniform coating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The cerium phosphate coated ternary positive electrode material of this embodiment is composed of a positive electrode material inner core and a cerium phosphate layer coated on the surface of the positive electrode material inner core; the positive electrode material is LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 ; The mass percentage of the cerium phosphate in the cerium phosphate-coated ternary positive electrode material is 1%.

[0026] The preparation method of the cerium phosphate-coated ternary positive electrode material of the present embodiment comprises the following steps:

[0027] 1) Weigh 0.192gCe(NO 3 ) 3 ·6H 2 O dissolved in a small amount of 10mL water, weighed 0.051g NH 4 h 2 PO 4 Dissolve in 10mL of water to prepare cerium nitrate solution and ammonium dihydrogen phosphate solution respectively;

[0028] Add 9.67g of positive electrode material into 50mL water, then stir at 500rpm for 1h, then add cerium nitrate solution, stir at 500rpm for 1h, then slowly ad...

Embodiment 2

[0032] The cerium phosphate-coated ternary positive electrode material of this embodiment is composed of a positive electrode material inner core and a cerium phosphate layer coated on the surface of the positive electrode material inner core; the positive electrode material is LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The mass percentage of the cerium phosphate in the cerium phosphate-coated ternary positive electrode material is 0.1%.

[0033] The preparation method of the cerium phosphate-coated ternary positive electrode material of the present embodiment comprises the following steps:

[0034] 1) Weigh 0.192gCe(NO 3 ) 3 ·6H 2 Dissolve O in 10mL water, weigh 0.051g NH 4 h 2 PO 4 Dissolve in 10mL of water to prepare cerium nitrate solution and ammonium dihydrogen phosphate solution respectively;

[0035] Add 99.9g of positive electrode material into 500mL of water, then stir at 700rpm for 0.5h, then add cerium nitrate solution, stir at 300rpm for 5h, then slowly add ammonium dihy...

Embodiment 3

[0039] The cerium phosphate-coated ternary positive electrode material of this embodiment is composed of a positive electrode material inner core and a cerium phosphate layer coated on the surface of the positive electrode material inner core; the positive electrode material is LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 ; The mass percent of the cerium phosphate in the cerium phosphate-coated ternary positive electrode material is 5%.

[0040]The preparation method of the cerium phosphate-coated ternary positive electrode material of the present embodiment comprises the following steps:

[0041] 1) Weigh 0.96gCe(NO 3 ) 3 ·6H 2 Dissolve O in 50mL water, weigh 0.255g NH 4 h 2 PO 4 Dissolve in 50mL water, and prepare cerium nitrate solution and ammonium dihydrogen phosphate solution respectively;

[0042] Add 9.88g of positive electrode material into 50mL of water, then stir at 300rpm for 2h, then add cerium nitrate solution, stir at 700rpm for 0.2h, then slowly add ammonium dihydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com