Getter for vacuum insulation board and vacuum insulation board

A technology of vacuum insulation panels and getters, which is applied in heat exchange equipment, pipeline protection through heat insulation, heat preservation, etc., can solve the problems of activation of getters, violent oxidation reactions, cumbersome methods and procedures, etc., and achieve low cost, The effect of safe and convenient operation and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In the present application, the preparation method of the getter for vacuum insulation panels preferably includes the following steps:

[0042] In the presence of a first protective gas, mixing the first powder and a desiccant to obtain a powder;

[0043] In the presence of the second protective gas, the powder is packaged into a bag with the material of an outer packaging bag to obtain a getter for a vacuum insulation panel.

[0044] In the embodiment of the present application, firstly, the desiccant and the first powder are mixed under the protection of the first protective gas, preferably for 4h to 5h, to obtain the powder. Wherein, the first protective gas is preferably nitrogen or an inert gas such as argon; the mixing is a technical means well known to those skilled in the art, and there is no special limitation in this application.

[0045] After the powder is obtained, the embodiment of the present application preferably uses an automatic packaging machine to ...

Embodiment 1

[0055] Under the protection of an inert gas, according to the mass ratio of 0.93:0.07, mix the calcium oxide and the first powder for 4 hours, and then use Dupont paper to package it into a bag under the protection of an inert gas to obtain a getter for vacuum insulation panels; wherein, the The first powder is CuO and MnO 2 The composite oxide, and the mass ratio of the two is 0.4:0.6.

[0056] According to the method described above, the getter performance test was carried out on the getter for vacuum insulation panels. The results show that its hydrogen absorption capacity reaches 6.1Pa·L / mg (the amount of gas that can be absorbed per milligram of powder), and its carbon monoxide and oxygen absorption capacities are 3.1Pa·L / mg and 2.4Pa·L / mg respectively.

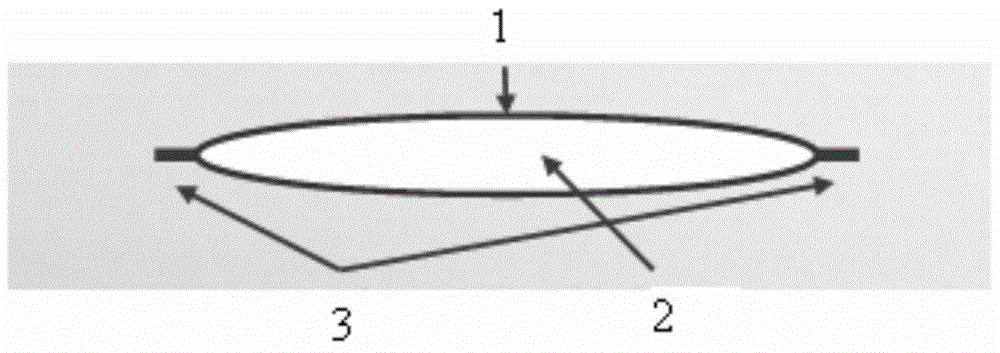

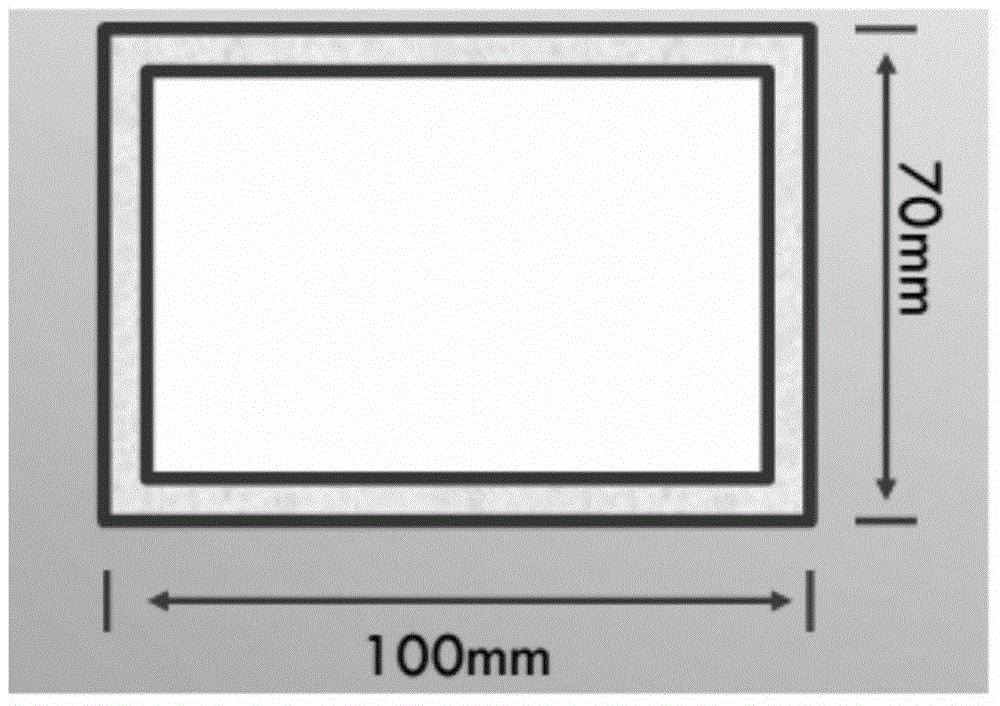

[0057] The getter, the core material and the gas barrier layer are assembled to obtain a vacuum insulation panel; wherein, the core material is glass fiber, and the gas barrier layer is a composite aluminum foil bag.

...

Embodiment 2

[0060] Under the protection of an inert gas, according to the mass ratio of 0.9:0.1, mix the calcium oxide and the first powder for 4 hours, and then use DuPont paper to package it into a bag under the protection of an inert gas to obtain a getter for vacuum insulation panels; wherein, the The first powder is CuO, MnO 2 、Co 2 o 3 and Ag 2 A composite oxide of O, and the mass ratio of the four is 0.3:0.5:0.15:0.05.

[0061] According to the method described above, the getter performance test was carried out on the getter for vacuum insulation panels. The results show that its hydrogen absorption capacity reaches 6.5Pa·L / mg, and its carbon monoxide and oxygen absorption capacities are 3.2Pa·L / mg and 2.2Pa·L / mg respectively.

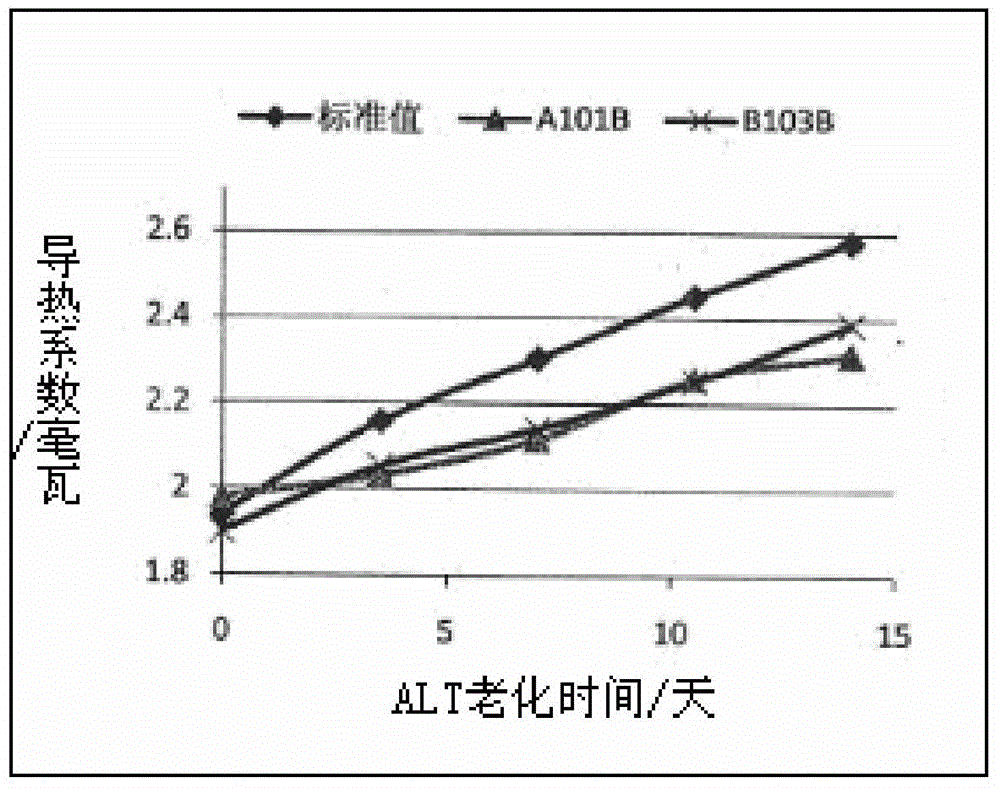

[0062] The getter was assembled according to the method of Example 1 to obtain a vacuum insulation panel. According to the method described above, the aging test was carried out on the vacuum insulation panel (recorded as L08, corresponding to B103B), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com