Ferrous-manganese combined metal oxide magnetic nanofiber with pipe-in-pipe structure and preparation method of ferrous-manganese combined metal oxide magnetic nanofiber

A magnetic nano-composite metal technology, applied in fiber processing, textiles and papermaking, artificial filaments made of inorganic raw materials, etc., to achieve the effect of not easy to hydrolyze, easy to prepare, and easy to operate in the spinning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 0.4040g Fe(NO 3 ) 3 9H 2 O and 0.72g 50wt% Mn(NO 3 ) 2 Add the solution into a beaker containing 6 mL of DMF, stir until it is completely dissolved to obtain a transparent and uniform solution, then add 1g of PVP, mix and stir evenly, and obtain a transparent and viscous spinning solution;

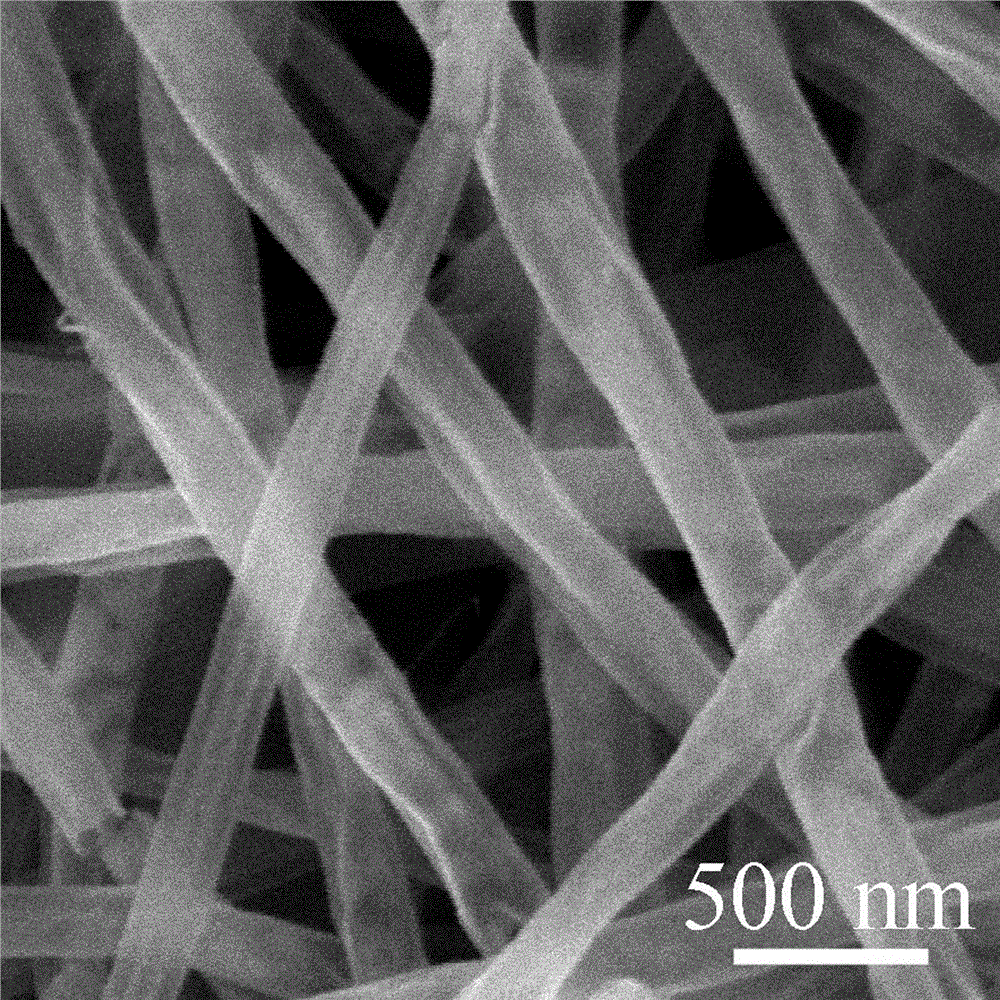

[0031] (2) Pour the spinning solution prepared in step (1) into a syringe with a stainless steel needle with an outer diameter of 0.8 mm for electrospinning, and control the indoor temperature and relative humidity at about 25°C and 30%, respectively. The distance from the receiving plate was adjusted to 15 cm, the propulsion speed of the spinning solution was 0.9 mL / h, the voltage of the electrospinning process was 15 kV, and the composite nanofibers of iron-manganese metal salt and polyvinylpyrrolidone were collected by the receiver;

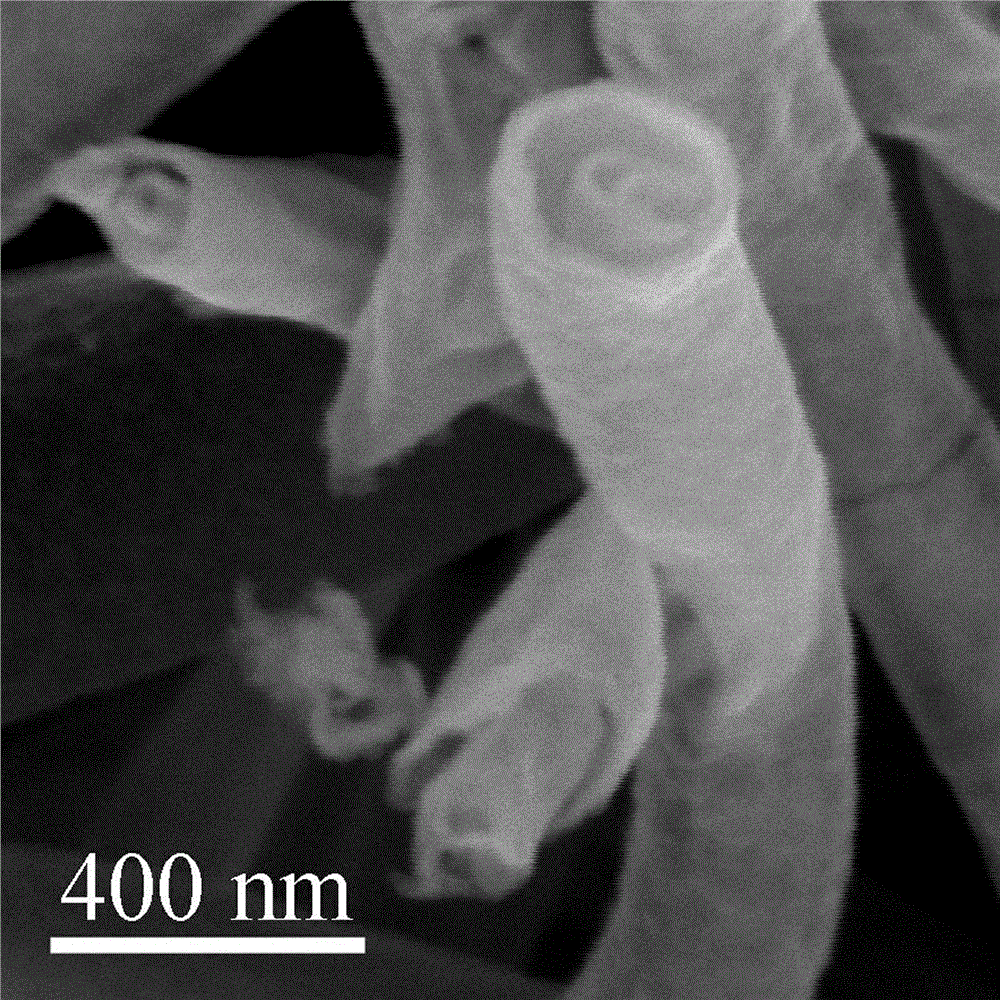

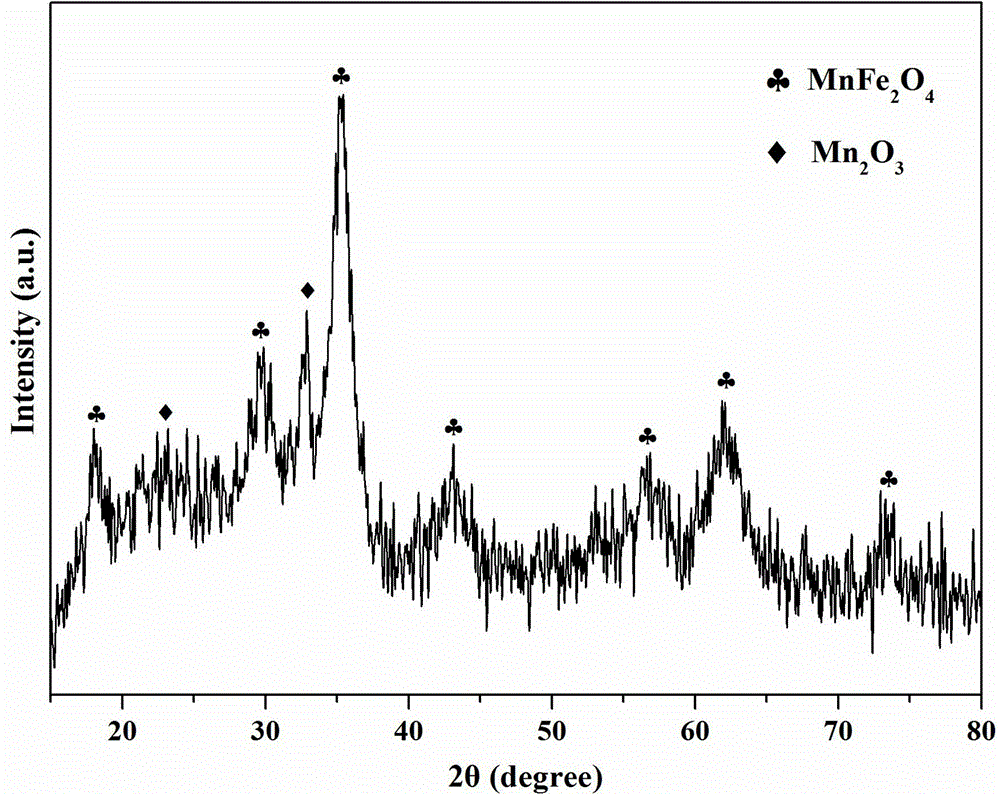

[0032] (3) The composite fiber prepared in step (2) is calcined in sections. In the first stage, the temperature is raised to 300°C a...

Embodiment 2

[0035] (1) Weigh 0.4040g Fe(NO 3 ) 3 9H 2 O and 0.17g MnSO 4 · h 2 O was added to a beaker containing 6 mL of DMF, stirred until all dissolved to obtain a transparent and uniform solution, then added 1.2 g of PVP, mixed and stirred evenly, to obtain a transparent and viscous spinning solution;

[0036] (2) Pour the spinning solution prepared in step (1) into a syringe with a stainless steel needle with an outer diameter of 0.8 mm for electrospinning, and control the indoor temperature and relative humidity at about 20°C and 20%, respectively. The distance from the receiving plate was adjusted to 17 cm, the propulsion speed of the spinning solution was 0.9 mL / h, and the voltage of the electrospinning process was 18 kV. The composite nanofibers of iron-manganese metal salt and polyvinylpyrrolidone were collected by the receiving plate;

[0037] (3) Calcinate the composite fibers prepared in step (2) in stages. In the first stage, the temperature is raised to 350°C at a heat...

Embodiment 3

[0039] (1) Weigh 0.4000g Fe respectively 2 (SO 4 ) 3 and 0.36g of 50wt% Mn(NO 3 ) 2 Add the solution into a beaker containing 6 mL of DMF, stir until it is completely dissolved to obtain a transparent and uniform solution, then add 1g of PVP, mix and stir evenly, and obtain a transparent and viscous spinning solution;

[0040] (2) Pour the spinning solution prepared in step (1) into a syringe with a stainless steel needle with an outer diameter of 0.8 mm for electrospinning, and control the indoor temperature and relative humidity at about 15°C and 35%, respectively. The distance from the receiving plate was adjusted to 20 cm, the propulsion speed of the spinning solution was 0.9 mL / h, and the voltage during the electrospinning process was 16 kV. The composite nanofibers of iron-manganese metal salt and polyvinylpyrrolidone were collected by the receiving plate;

[0041] (3) The composite fiber prepared in step (2) is calcined in sections. In the first stage, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com