Controllable regulation and control method of Na2/3Mn1/2Fe1/4Co1/4O2 positive electrode material of sodium-ion battery meeting high-rate discharge cycle performance

A sodium-ion battery, high-rate discharge technology, applied to battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of slow heating rate and long reaction time, and achieve fast reaction speed, high specific capacity and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

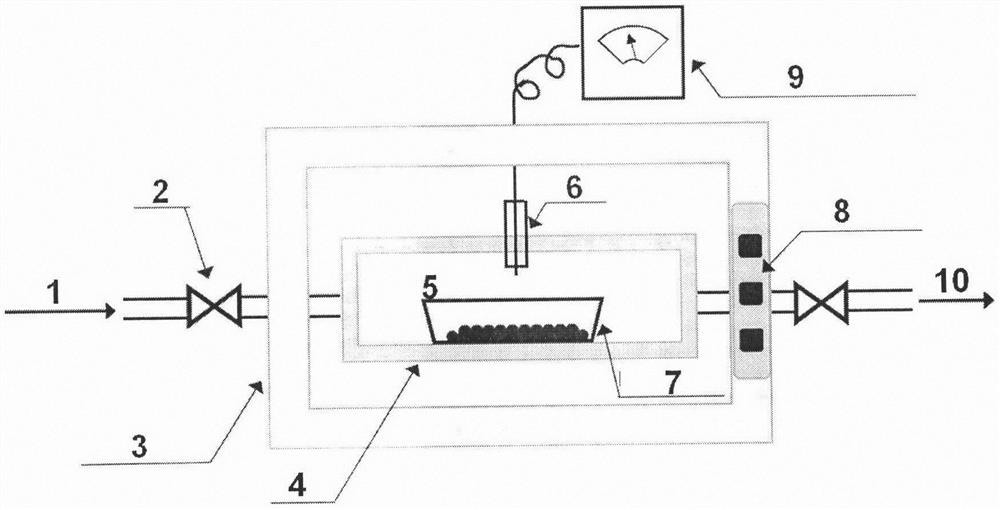

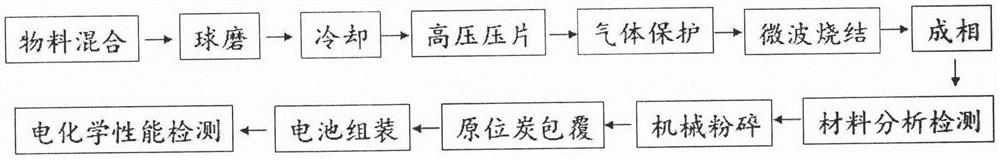

[0019] Example 1: The pressure is 10Mpa, 1100 ℃ microwave radiation solid-phase reaction for 6 hours, the preparation of Na 2 / 3 mn 1 / 2 Fe 1 / 4 co 1 / 4 o 2 Cathode material

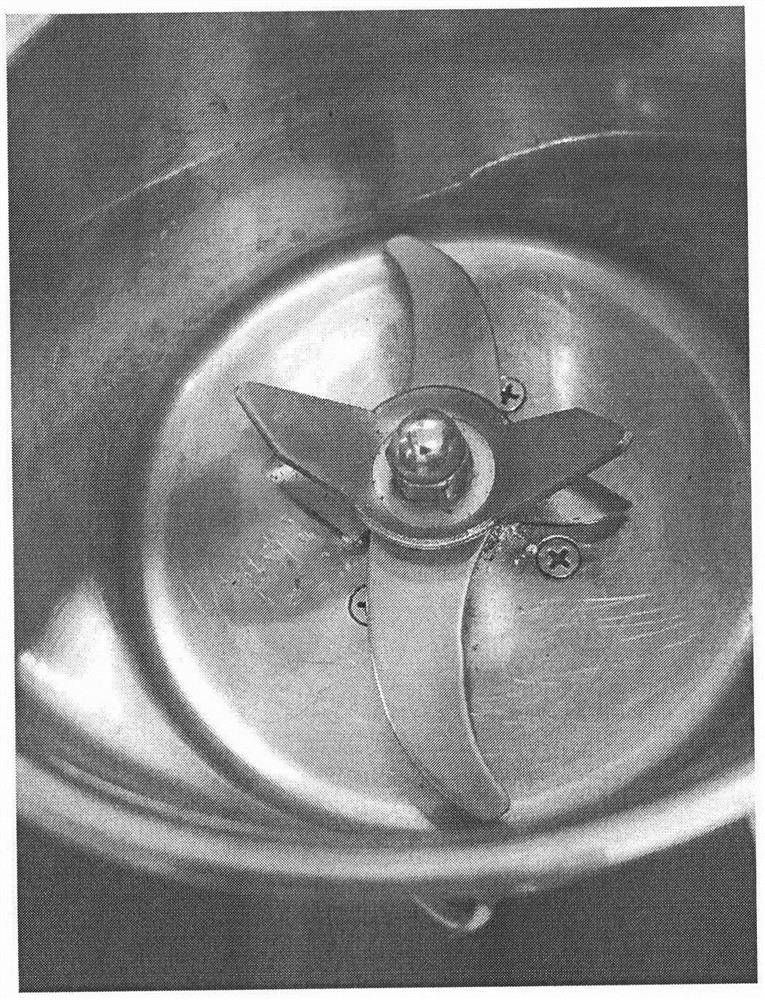

[0020] First, at room temperature, according to Na 2 / 3 mn 1 / 2 Fe 1 / 4 co 1 / 4 o 2 The stoichiometric ratio Na: Mn: Fe: Co=2 / 3: 1 / 2: 1 / 4: 1 / 4, accurately weigh analytically pure sodium carbonate (molecular formula is Na 2 CO 3 ), manganese trioxide (molecular formula is Mn 2 o 3 ), ferric oxide (molecular formula is Fe 2 o 3 ) and cobalt carbonate (molecular formula is CoCO 3 ) high-purity powder, the total material quality is 20.0000g, and the above four kinds of reaction raw material powders are transferred to a planetary ball mill tank with a volume of 200ml; the grinding ball is and 304 material stainless steel ball, and The weight ratio is 2:1; the total weight ratio of grinding balls to materials is 10:1; and add 50mL of analytical pure ethanol, cover the ball mill jar tightly and ...

Embodiment 2

[0021] Example 2: The pressure is 20MPa, 1000 ℃ microwave radiation solid phase reaction for 10 hours, the preparation of Na 2 / 3 mn 1 / 2 Fe 1 / 4 co 1 / 4 o 2 Cathode material

[0022] First, at room temperature, according to Na 2 / 3 mn 1 / 2 Fe 1 / 4 co 1 / 4 o 2 The stoichiometric ratio Na: Mn: Fe: Co=2 / 3: 1 / 2: 1 / 4: 1 / 4, accurately weigh analytically pure sodium carbonate (molecular formula is Na 2 CO 3 ), manganese trioxide (molecular formula is Mn 2 o 3 ), ferric oxide (molecular formula is Fe 2 o 3 ) and cobalt carbonate (molecular formula is CoCO 3 ) high-purity powder, the total material quality is 20.0000g, and the above four kinds of reaction raw material powders are transferred to a planetary ball mill tank with a volume of 200ml; the grinding ball is and 304 material stainless steel ball, and The weight ratio of the grinding ball to the material is 10:1; add 40mL of analytical pure ethanol, cover the ball mill jar tightly and put it into the ball mill. 1...

Embodiment 3

[0023] Example 3: The pressure is 15MPa, 1050 ℃ microwave radiation solid phase reaction for 8 hours, the preparation of Na 2 / 3 mn 1 / 2 Fe 1 / 4 co 1 / 4 o 2 Cathode material

[0024] First, at room temperature, according to Na 2 / 3 mn 1 / 2 Fe 1 / 4 co 1 / 4 o 2 The stoichiometric ratio Na: Mn: Fe: Co=2 / 3: 1 / 2: 1 / 4: 1 / 4, accurately weigh analytically pure sodium carbonate (molecular formula is Na 2 CO 3 ), manganese trioxide (molecular formula is Mn 2 o 3 ), ferric oxide (molecular formula is Fe 2 o 3 ) and cobalt carbonate (molecular formula is CoCO 3 ) high-purity powder, the total material quality is 20.0000g, and the above four kinds of reaction raw material powders are transferred to a planetary ball mill tank with a volume of 200ml; the grinding ball is and 304 material stainless steel ball, and The weight ratio is 2:1; the total weight ratio of grinding balls to materials is 10:1; and add 50mL of analytical pure ethanol, cover the ball mill jar tightly and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com