Ruthenium dioxide coated spinel lithium-rich lithium manganate and preparation method thereof

A technology of lithium-rich lithium manganate and ruthenium dioxide is applied in the field of ruthenium dioxide coating spinel lithium-rich manganate and its preparation, which can solve the problem of poor crystallinity of lithium-rich lithium manganate and poor overall performance of the material. Ideal, poor cycle performance and other problems, to achieve the effect of improving high-temperature storage and cycle performance, high crystallinity, and low post-processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

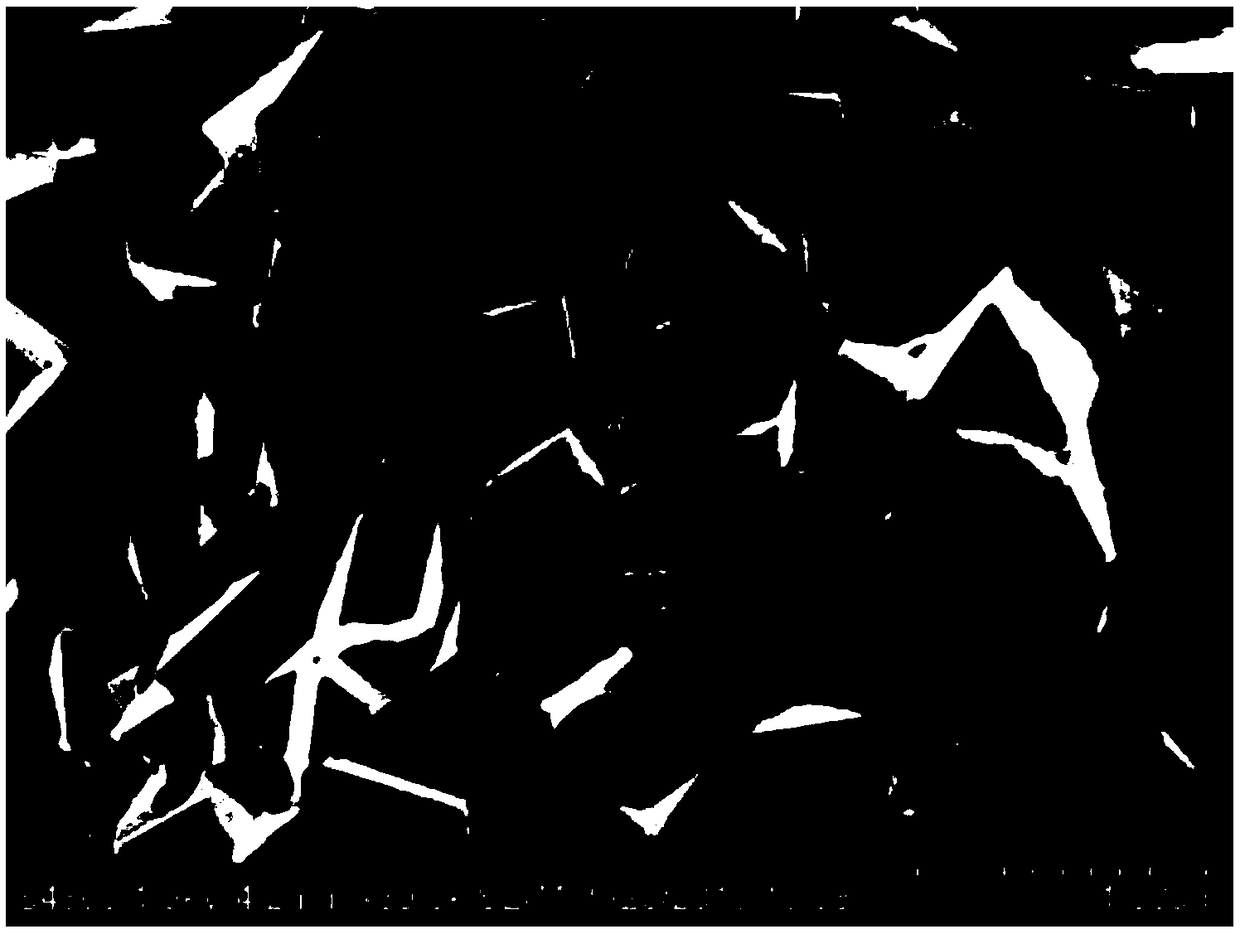

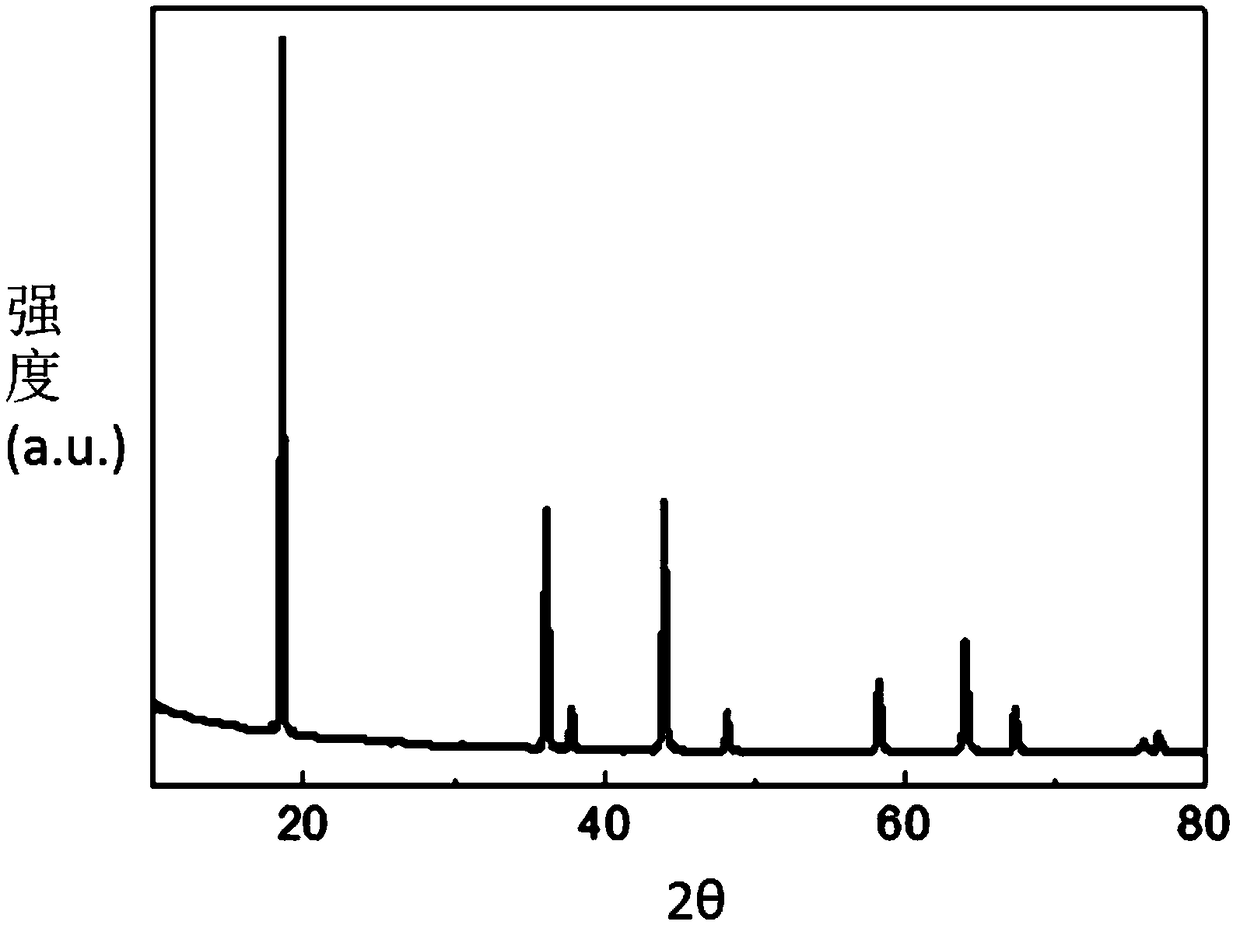

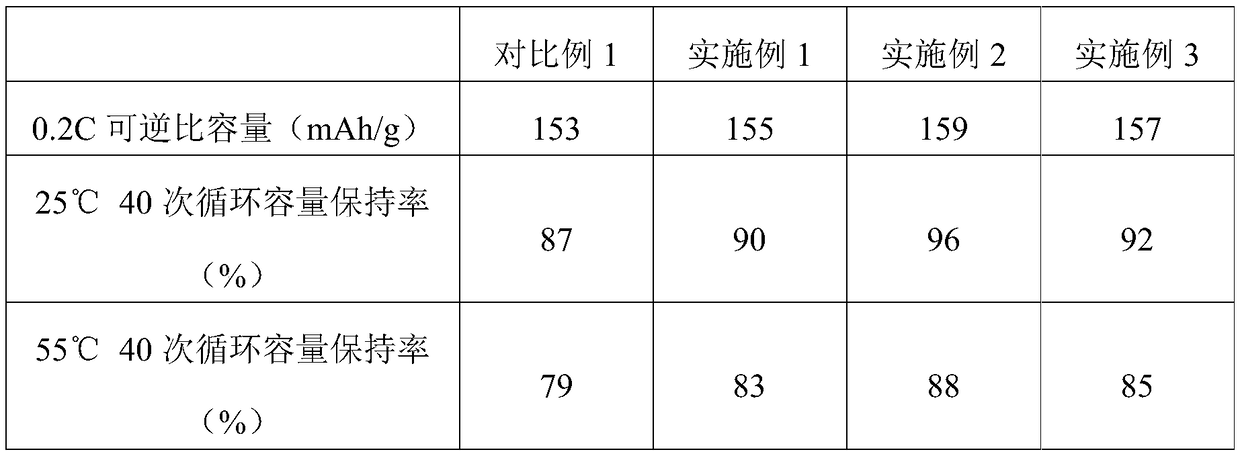

[0040] Weigh 1g of manganese trioxide, add it to 50mL, 5mol / L NaOH solution, stir for 0.5h to obtain a uniformly mixed precursor solution, transfer the precursor solution into a microwave reactor, heat at 180°C for 6h, and wash the product with water , to a pH value of 7, and dried in an oven at 80°C. Mix the above product with 0.7g of lithium nitrate and 1.72g of potassium chloride, grind it evenly, react in molten salt at 480°C for 10 hours, wash the product with water until it is free of chlorine, and dry it to obtain spinel lithium-rich lithium manganese oxide. high magnification scanning electron microscope see figure 1 ,Depend on figure 1 It can be seen that the spinel lithium-rich lithium manganate octahedral crystal form obtained according to the above method is complete and the particle size is uniform; the X-ray diffraction diagram is shown in figure 2 ,Depend on figure 2 It can be seen that the spinel lithium-rich lithium manganese oxide prepared according to t...

Embodiment 2

[0044] Weigh 1g of manganese trioxide, add it to 50mL, 5mol / L NaOH solution, stir for 0.5h to obtain a uniformly mixed precursor solution, transfer the precursor solution into a microwave reactor, heat at 180°C for 6h, and wash the product with water , to a pH value of 7, and dried in an oven at 80°C. Mix the above product with 0.7g of lithium nitrate and 1.72g of potassium chloride, grind it evenly, react in molten salt at 480°C for 10 hours, wash the product with water until it is free of chlorine, and dry it to obtain spinel lithium-rich lithium manganese oxide.

[0045] Weigh the mass ratio of spinel lithium-rich lithium manganate: ruthenium chloride = 100:8.58, first dissolve ruthenium chloride in deionized water to make a solution, and evenly disperse the spinel lithium-rich lithium manganate in the chloride Ruthenium (RuCl 3 ) aqueous solution, stir at room temperature for 1-2h, add 1mol / L sodium hydroxide solution dropwise until the reaction is complete, continue to s...

Embodiment 3

[0047] Weigh 1g of manganese trioxide, add it to 50mL, 5mol / L NaOH solution, stir for 0.5h to obtain a uniformly mixed precursor solution, transfer the precursor solution into a microwave reactor, heat at 180°C for 6h, and wash the product with water , to a pH value of 7, and dried in an oven at 80°C. Mix the above product with 0.7g of lithium nitrate and 1.72g of potassium chloride, grind it evenly, react in molten salt at 480°C for 10 hours, wash the product with water until it is free of chlorine, and dry it to obtain spinel lithium-rich lithium manganese oxide.

[0048] Weigh the mass ratio of spinel lithium-rich lithium manganese oxide: ruthenium chloride = 100:15.6, first dissolve ruthenium chloride in deionized water to make a solution, and evenly disperse the spinel lithium-rich lithium manganate in the chloride Ruthenium (RuCl 3 ) aqueous solution, stir at room temperature for 1-2h, add 1mol / L sodium hydroxide solution dropwise until the reaction is complete, continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com