Manufacturing method of stainless non-stick pan and apparatus thereof

A manufacturing method and technology of non-stick pans, applied in the field of pan manufacturing, to achieve the effects of overcoming hazards, optimizing parameter control, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

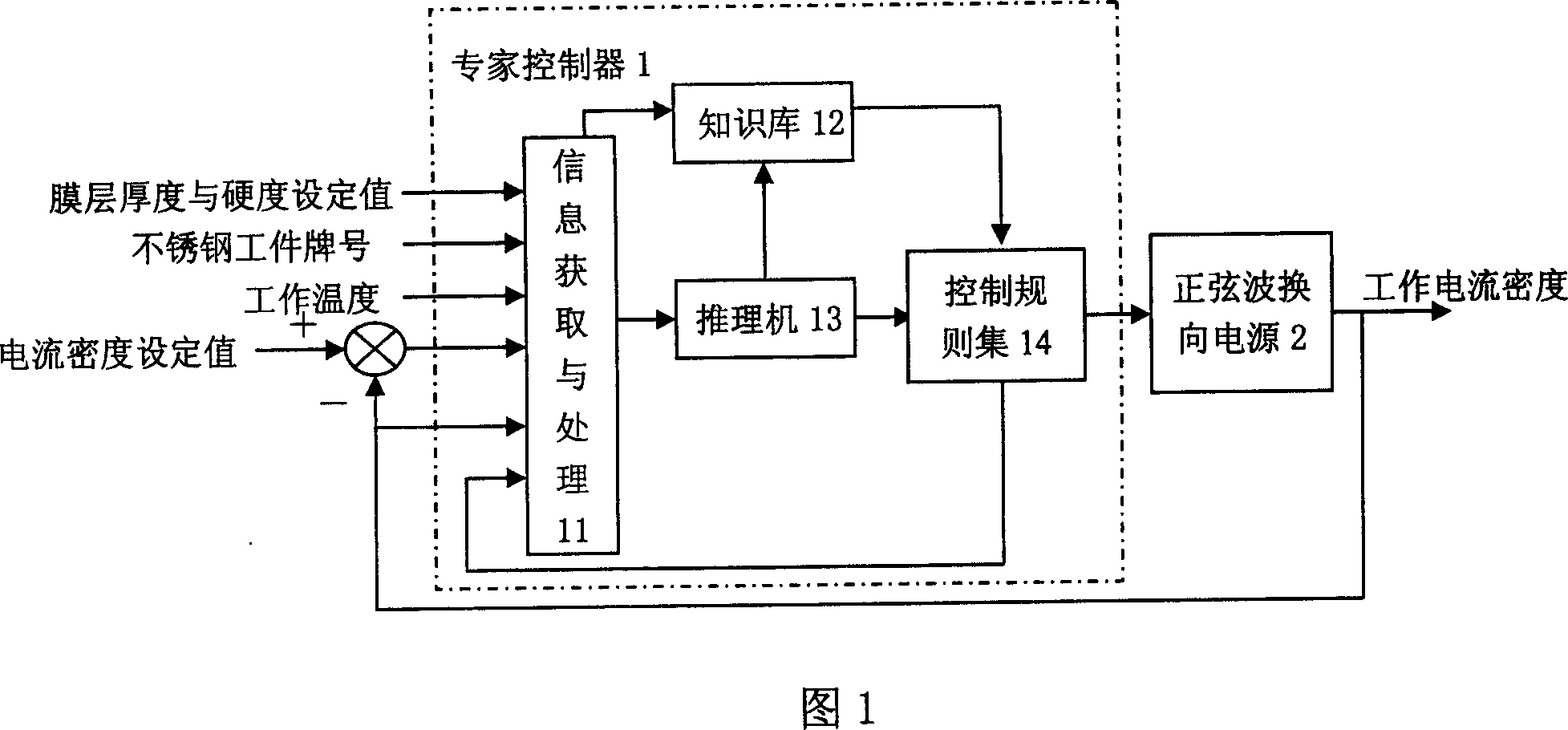

[0016] The invention relates to a manufacturing method of a stainless steel non-stick pan. Firstly, the stainless steel raw material is placed in a mold for stamping. The stainless steel can also be a stainless steel composite material, that is, interlayers such as aluminum and copper are arranged in the stainless steel to increase the pot body. Excellent heating speed and uniformity, as long as the inner surface of the non-stick pan is made of stainless steel. Then the inner surface of the non-stick pan is mechanically polished, degreased and cleaned to reduce the influence of the surface state of the workpiece and possible impurities on the subsequent wear-resistant process. Next, place the non-stick pan in the micro-arc oxidation grinding and polishing electrolyte solution, switch on the sine wave commutation power supply 2 equipped with the expert controller 1, apply a sine wave with a voltage of 30-120V on the non-stick pan, Micro-arc discharge is generated on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com