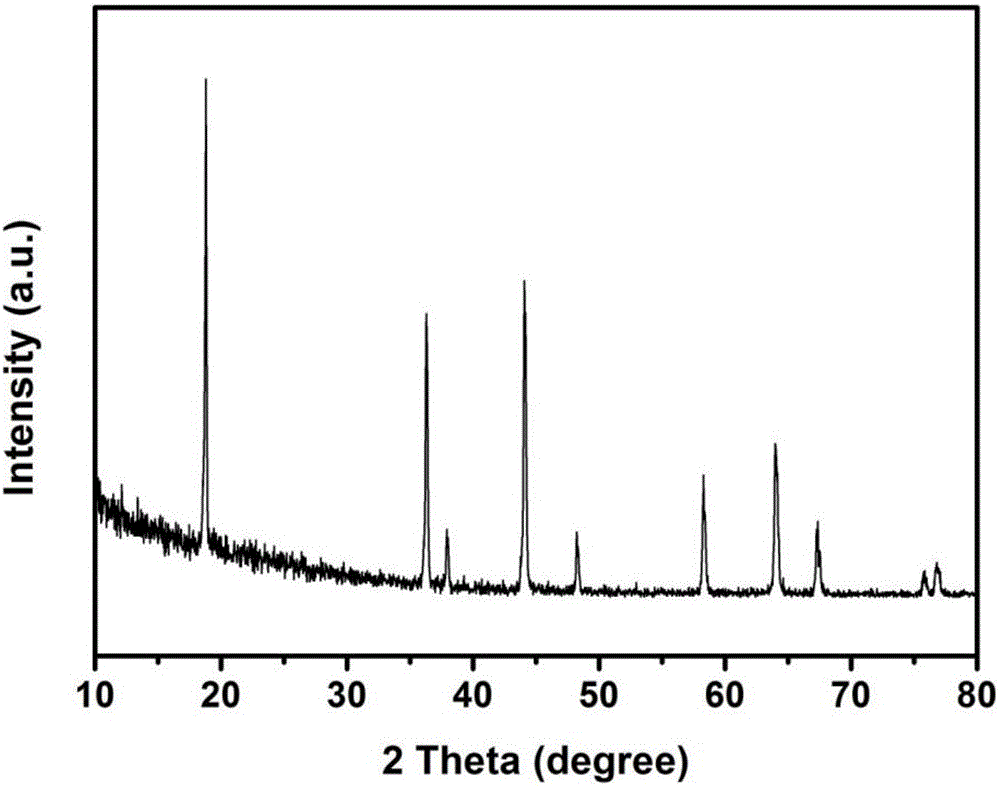

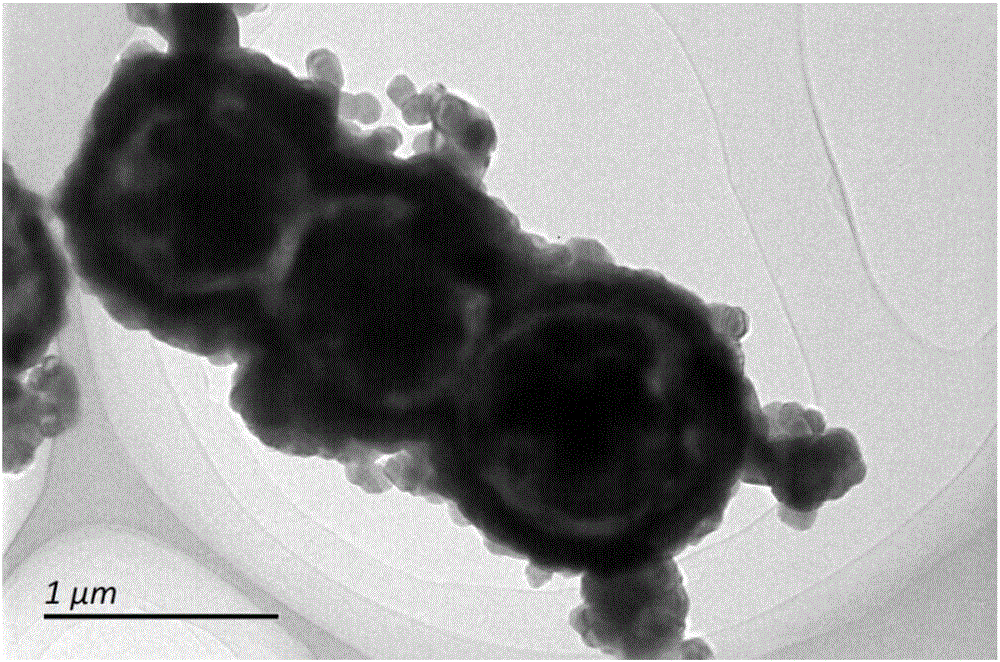

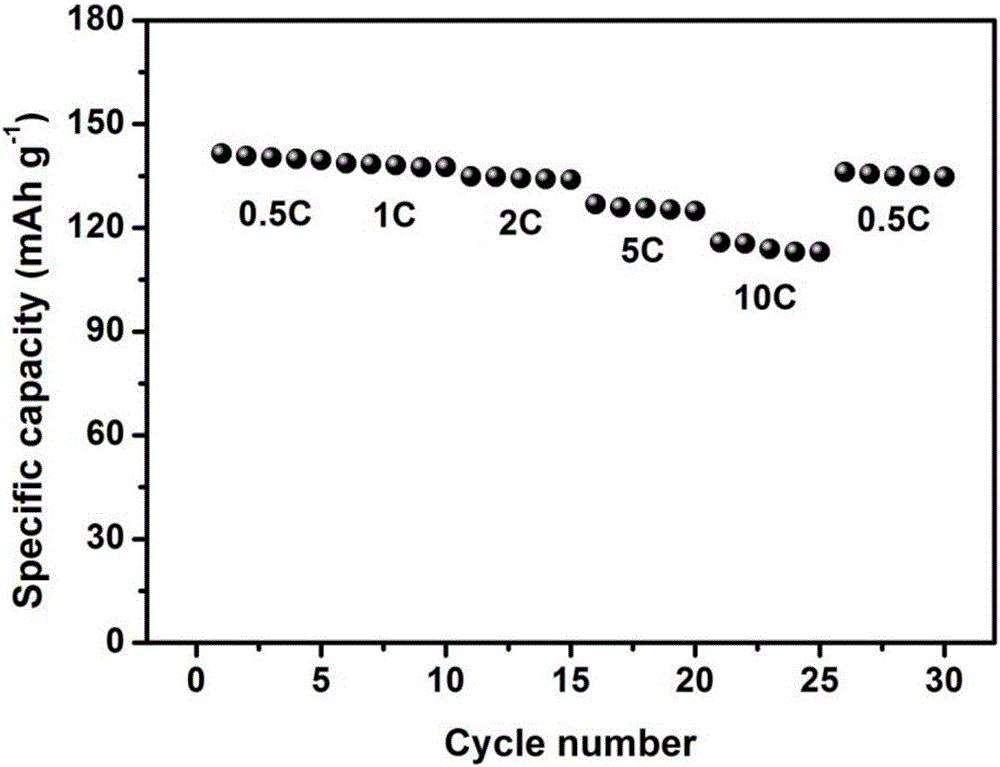

Preparation method for lithium ion battery manganese-based cathode materials of egg yolk-egg shell structure

A lithium-ion battery, eggshell technology, applied in battery electrodes, structural parts, circuits, etc., can solve problems such as unreported, and achieve the effects of high reaction yield, uniform morphology and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Manganese nitrate and urea are dissolved in deionized water respectively, the molar concentration of manganese ions in the solution after dissolving is 1mol / L, and the molar concentration of urea is 1mol / L, and it is standby after fully dissolving;

[0022] (2) Mix the two solutions obtained in step (1), the mixing ratio is that the molar ratio of manganese ions to urea is 1:3; condense and reflux for 60 minutes under the microwave excitation heating condition with a power of 700W, and cool to room temperature naturally Centrifugal separation obtains manganese carbonate precursor;

[0023] (3) Put the manganese carbonate precursor obtained in the previous step into a high-temperature furnace for heat treatment at 400°C for 5 hours, then cool to room temperature with the furnace to obtain egg yolk-eggshell structure manganese trioxide, and then mix with lithium hydroxide in ethanol Mix thoroughly, then dry at 120°C, grind for 30 minutes to obtain the precursor powder...

Embodiment 2

[0026] (1) Manganese acetate and sodium hydroxide are dissolved in deionized water and ethylene glycol respectively, and the molar concentration of manganese ion in the solution after dissolving is 0.1mol / L, and the molar concentration of sodium hydroxide is 0.5mol / L, fully ready after dissolving;

[0027] (2) two kinds of solutions that step (1) gained are mixed, and the mixing ratio is that the mol ratio of manganese ion and sodium hydroxide is 1:1; Under the microwave excitation heating condition that power is 700W, condense and reflux for 60 minutes, cool naturally to centrifugation after room temperature to obtain the manganese carbonate precursor;

[0028] (3) Put the manganese carbonate precursor obtained in the previous step into a high-temperature furnace for heat treatment at 450°C for 6 hours, then cool down to room temperature with the furnace to obtain egg yolk-eggshell structure manganese trioxide, and then mix with lithium acetate and nickel chloride Fully mix in...

Embodiment 3

[0031] (1) manganese sulfate and sodium hydroxide are dissolved in deionized water and Virahol respectively, the molar concentration of manganese ion in the solution after dissolving is 0.2mol / L, and the molar concentration of sodium hydroxide is 0.5mol / L, fully ready after dissolving;

[0032] (2) two kinds of solutions that step (1) gained are mixed, and the mixing ratio is that the mol ratio of manganese ion and sodium hydroxide is 1:2; Under the microwave excitation heating condition that power is 700W, condense and reflux for 60 minutes, cool naturally to centrifugation after room temperature to obtain the manganese carbonate precursor;

[0033] (3) Put the manganese carbonate precursor obtained in the previous step into a high-temperature furnace for heat treatment at 500°C for 3 hours, then cool to room temperature with the furnace to obtain manganese trioxide with egg yolk-eggshell structure, and then mix with lithium carbonate, nickel sulfate, Cobalt nitrate was full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com