Reduced catalyst of mono fluorin, and preparation method and usage

A compound, a1-xmxb1-ynyo3 technology, applied in the field of electrochemistry and inorganic material synthesis, can solve the problems of complex and time-consuming preparation process, high energy consumption and other problems, and achieve the effect of obvious characteristic diffraction peaks, saving time and less impurity peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

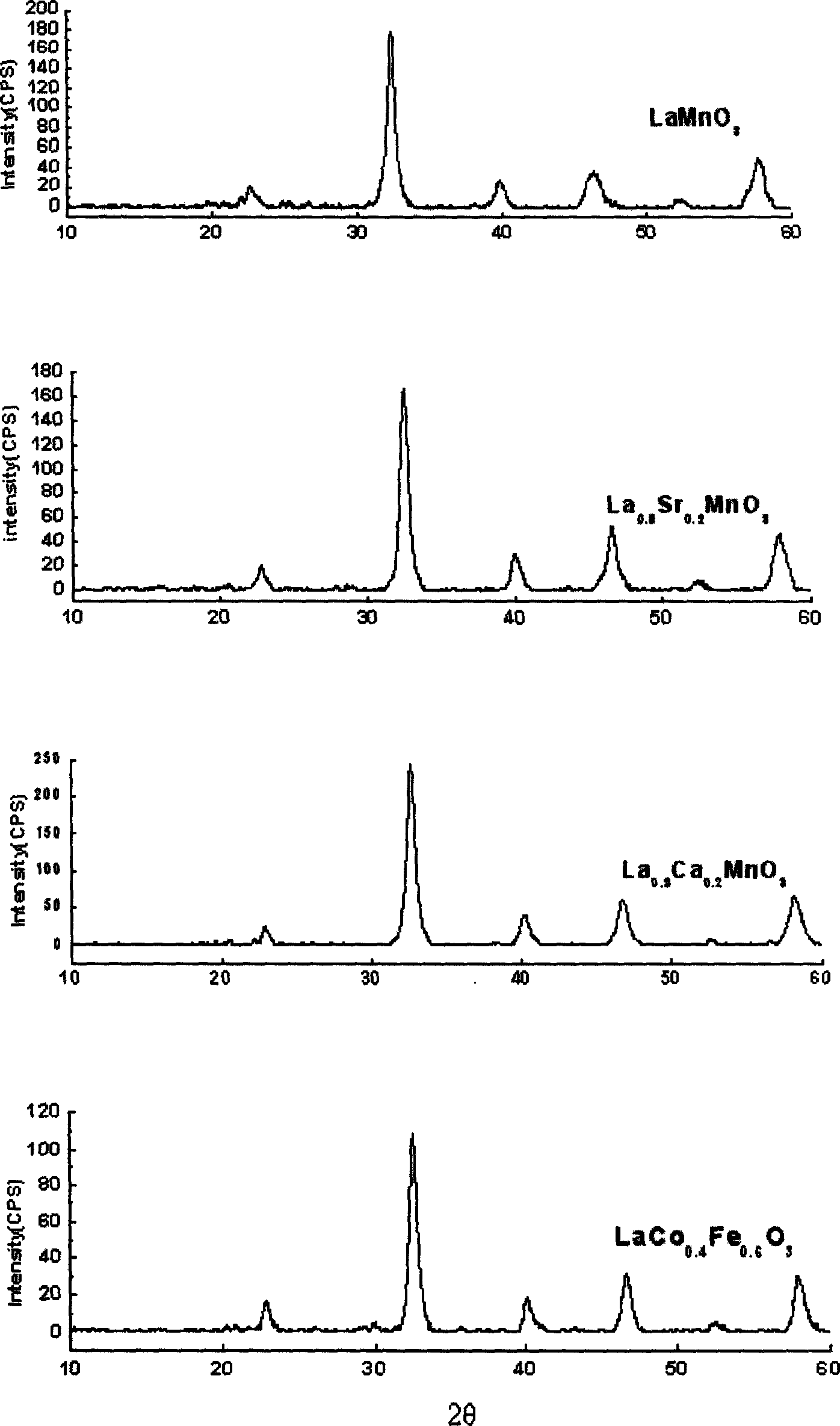

Embodiment 1

[0033] LaMnO 3 Synthesis, accurately weigh Mn 2 o 3 1.578g, La 2 o 3 2. Put 826g into the ball mill tank, put 12 stainless steel balls with a diameter of 8 mm and 8 stainless steel balls with a diameter of 10 mm, place the reaction tank on a swing vibration ball mill, and perform a swing vibration ball mill for 6 hours at room temperature, remove the stainless steel balls, and take out the catalyst Sealed for later use.

Embodiment 2

[0035] La 0.8 Sr 0.2 MnO 3 Synthesis, accurately weighed La 2 o 3 3.258g, Mn 2 o 3 1.578g, SrO 0.518g, MnO 2 0.435g. Rocking vibration ball milling for 2 hours, other steps as in Example 1.

Embodiment 3

[0037] La 0.8 Ca 0.2 MnO 3 Synthesis, accurately weighed La 2 o 3 3.258g, Mn 2 o 3 1.578g, CaO 0.28g, MnO 2 0.435g. Rocking vibration ball milling for 2 hours, other steps as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com