Lithium ion battery cathode material and preparation method for lithium ion battery cathode material

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as affecting structure and electrochemical stability, difficult to form cubic close-packed, and battery capacity attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

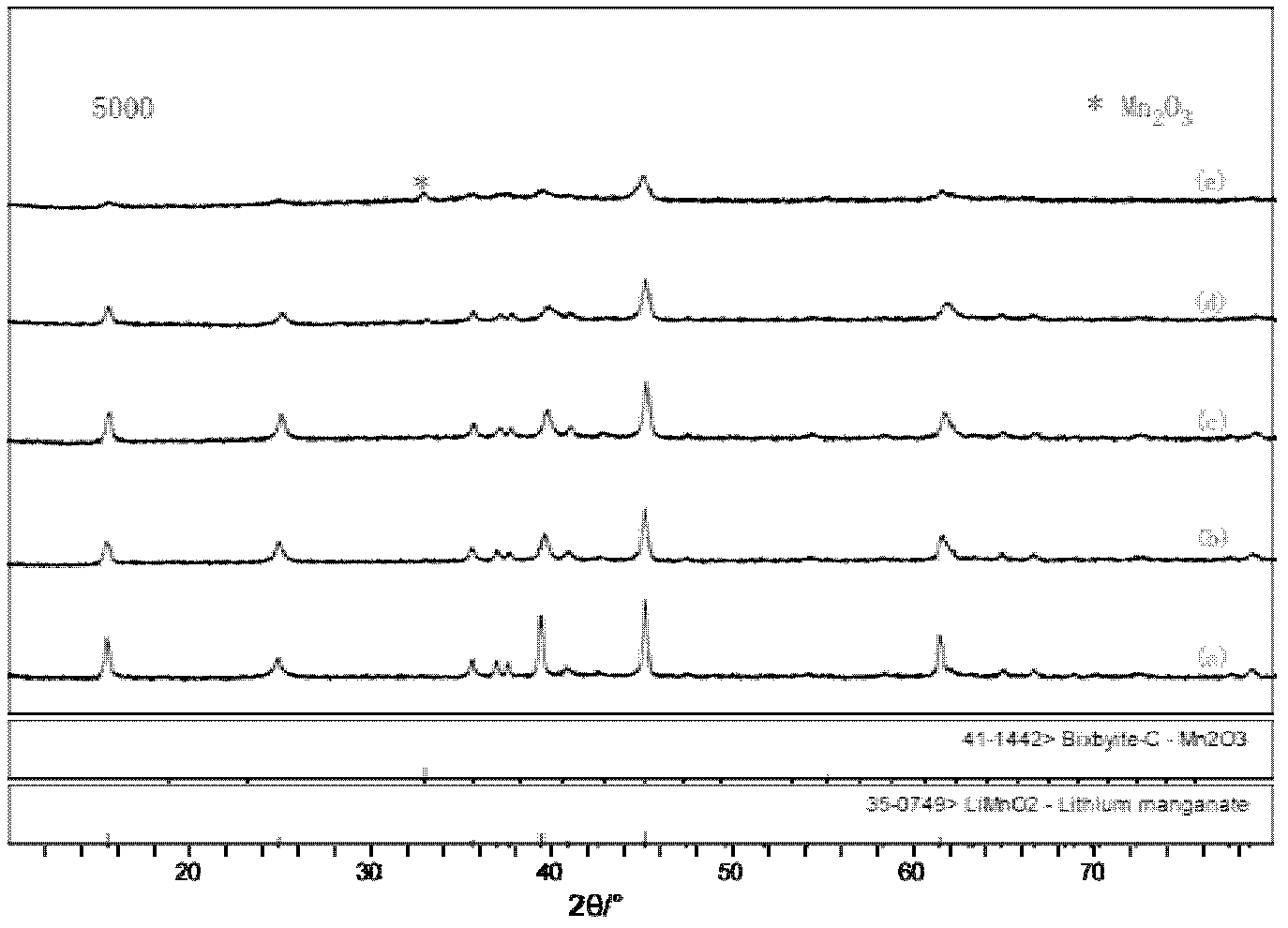

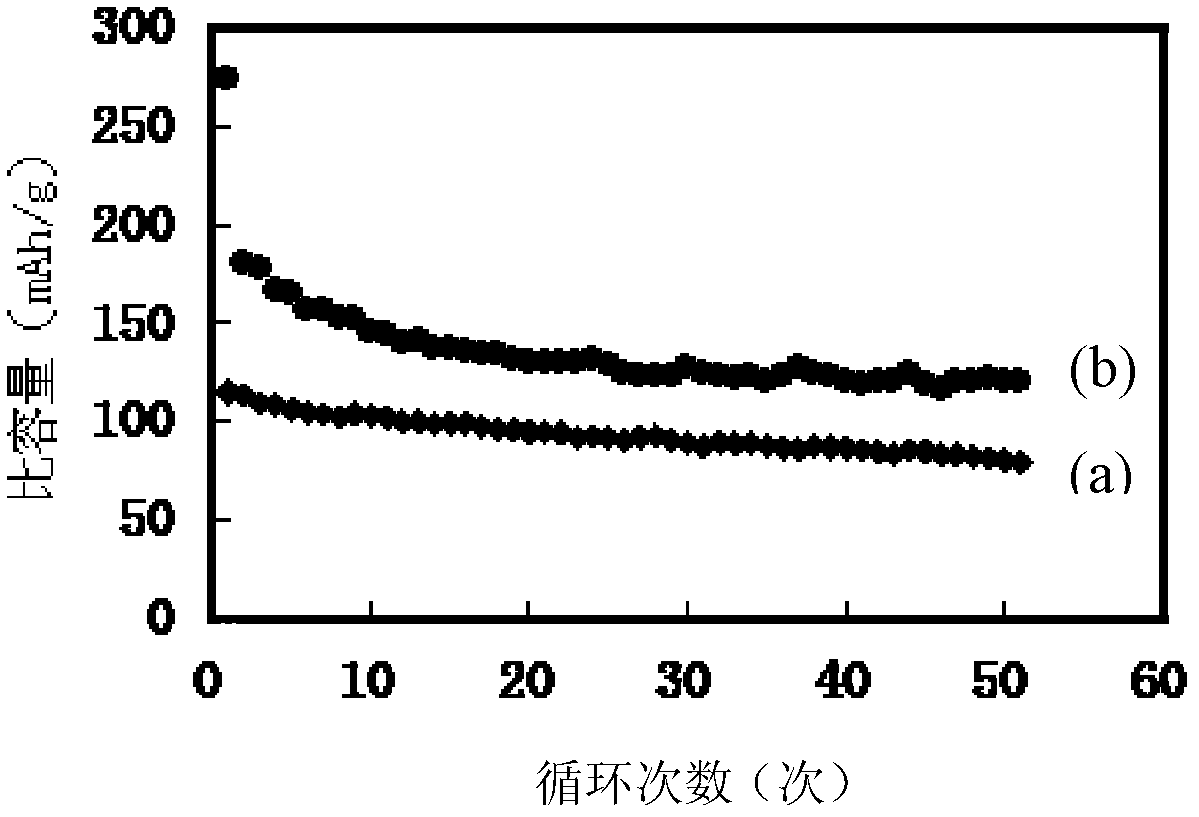

[0024] The invention provides lithium-ion battery cathode material LiMn x Al 1-x o 2 , the preparation method of 0.7≤x<1, comprising:

[0025] Dimanganese trioxide is dissolved in lithium hydroxide aqueous solution, and then aluminum oxide is added thereto to obtain a mixture, the molar ratio of lithium to manganese is 10:1 to 20:1, and the molar ratio of manganese trioxide to aluminum oxide is The ratio can be calculated according to 0.7≤xx Al 1-x o 2 , 0.7≤x<1.

[0026] If no aluminum oxide is added in the reaction, the final prepared sample is LiMnO 2 .

[0027] In addition, the preparation method provided by the invention is also applicable to the synthesis of other doped LiMn x m 1-x o 2 (M=Zn, Co, Ni, etc.) Lithium battery cathode material.

[0028] The present invention also provides a lithium battery positive electrode, including the lithium ion battery positive electrode material LiMn provided by the present invention x Al 1-x o 2 , 0.7≦x<1, and there are...

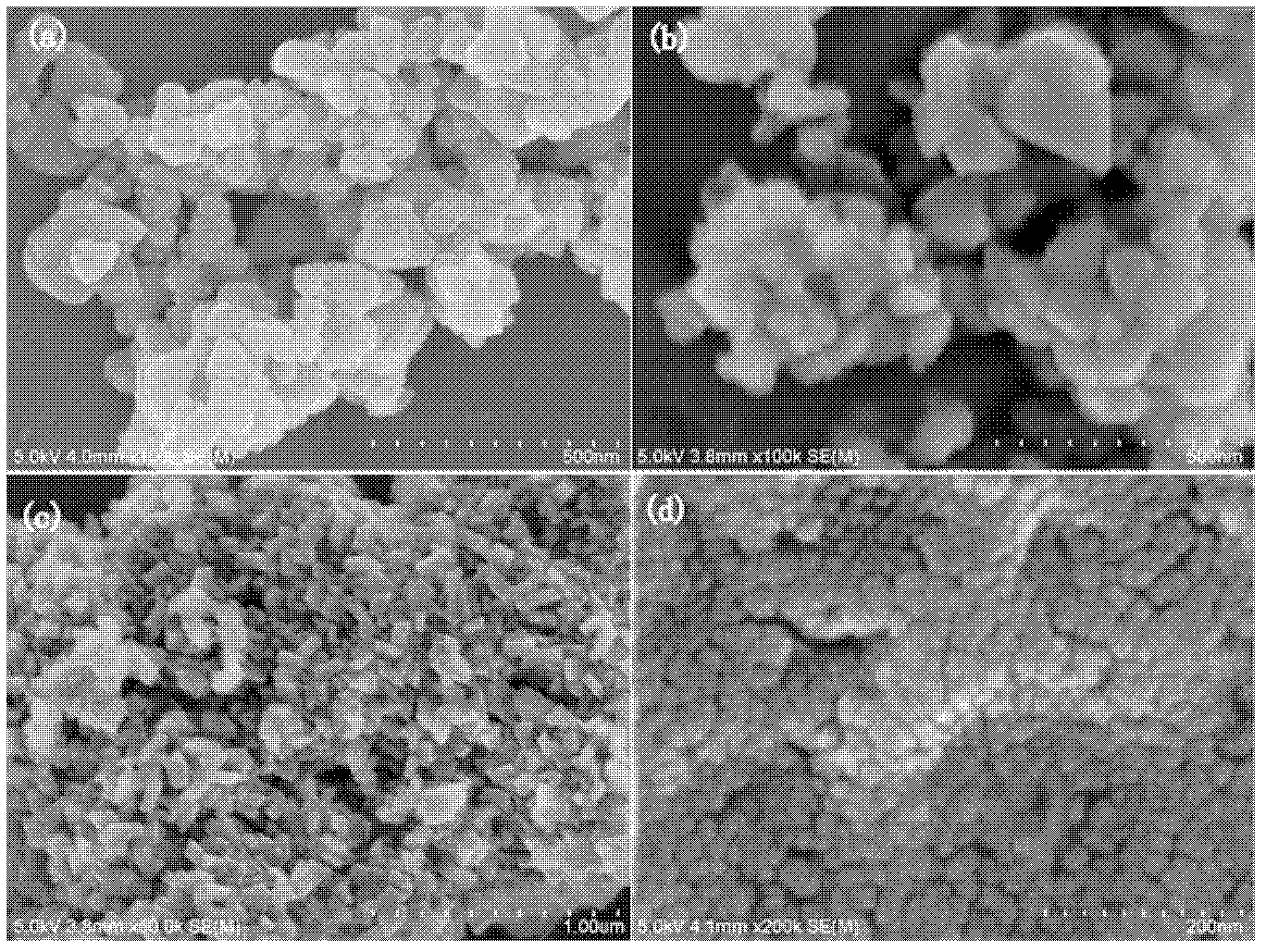

Embodiment 1

[0031] Dissolve 1 g of manganese trioxide in lithium hydroxide aqueous solution, the molar ratio of lithium to manganese is 10:1, add 0.034 g of aluminum oxide, stir for 10 minutes, transfer to a hydrothermal reaction kettle, and react at 150°C for 36 hours The sample was obtained, washed with water and dried overnight at 70°C to obtain LiMn 0.95 Al 0.05 o 2 .

Embodiment 2

[0033]Dissolve 1 g of manganese trioxide in lithium hydroxide aqueous solution, the molar ratio of lithium to manganese is 15:1, add 0.0715 g of aluminum oxide, stir for 10 minutes, transfer to a hydrothermal reaction kettle, and react at 130°C for 36 hours The sample was obtained, washed with water and dried overnight at 60°C to obtain LiMn 0.9 Al 0.1 o 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com