Preparation method for manganese oxide nano rods

A technology of manganese oxide nanorods and manganese oxides, which is applied in the field of nano functional materials preparation, can solve the problems of long preparation cycle, uneven size, high temperature, etc., and achieve the effect of easy control of shape, good repeatability and small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Add 0.075mmol of potassium permanganate into a beaker containing 44mL of distilled water, and stir under the action of a magnetic stirrer to obtain a purple-red solution; then add 0.6mL of ethylene glycol to the potassium permanganate solution and continue stirring for 5 A mixed solution with a black precipitate can be obtained in 1 hour. The mixed solution was put into a 50mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle and heated in an intelligently temperature-controllable heating furnace. The reaction conditions were: reaction temperature 120°C, reaction time 3 hours. After natural cooling, the hydrothermal product was centrifuged, washed three times with distilled water and absolute ethanol, and then dried in vacuum at 60° C. for 24 hours to obtain a light brown powder.

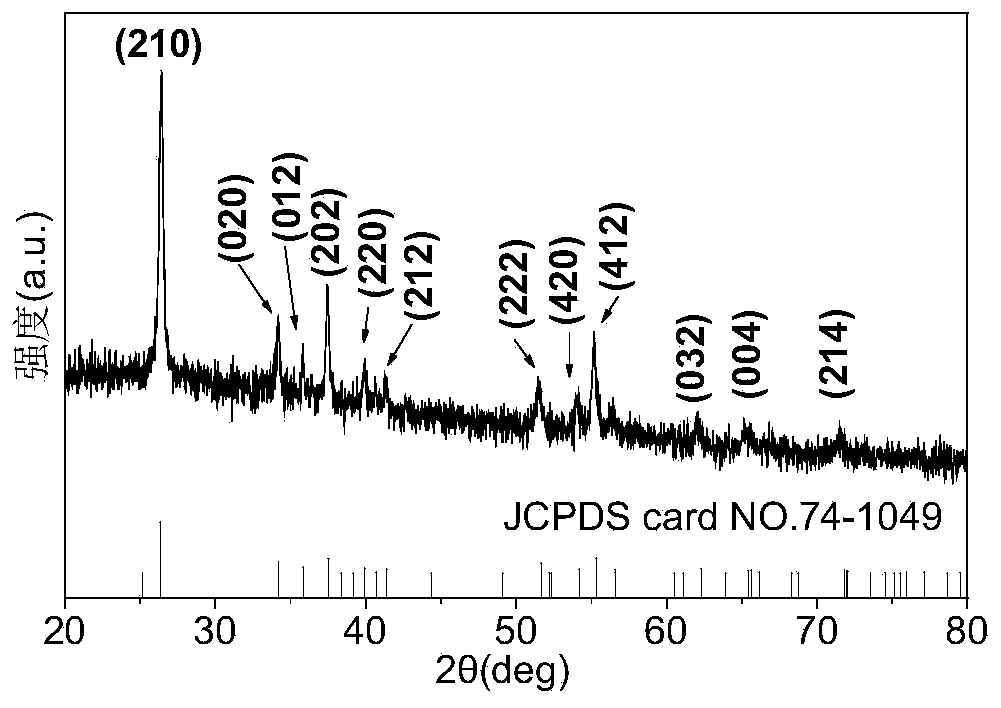

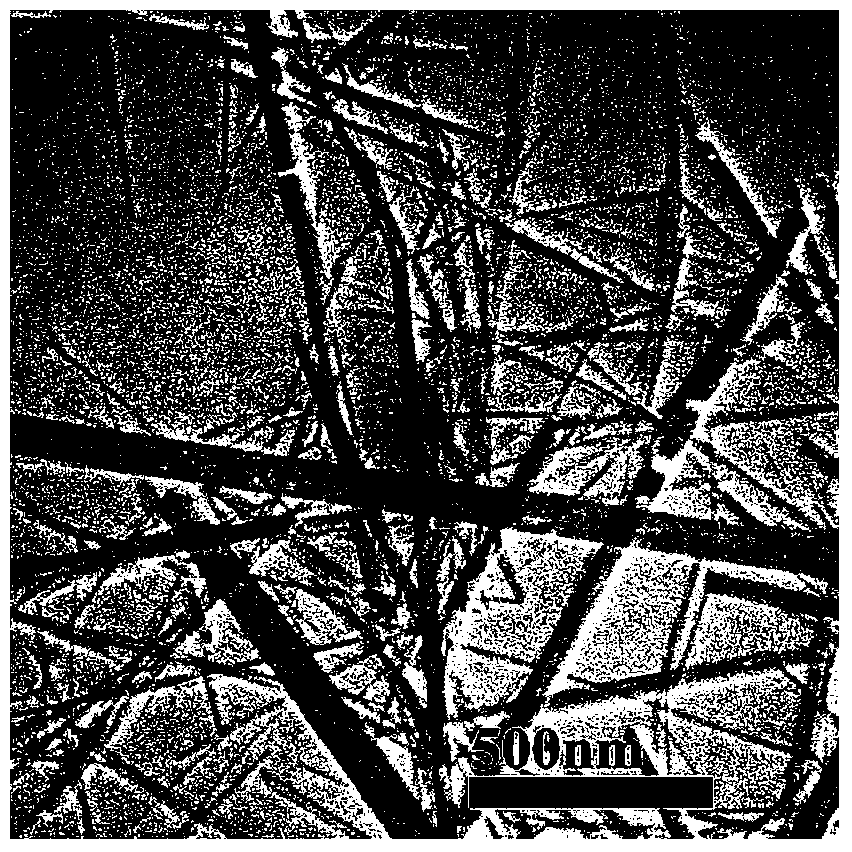

[0056] Its XRD spectrum is as figure 1 As shown, the analytical XRD spectrum shows that the prepared sample has a good crystal structure, and the product is basic ma...

Embodiment 2

[0058] Add 0.075mmol of potassium permanganate into a beaker containing 44mL of distilled water, and stir under the action of a magnetic stirrer to obtain a purple-red solution; then add 1.0mL of ethylene glycol to the potassium permanganate solution and continue stirring for 5 A mixed solution with a black precipitate can be obtained in 1 hour. The mixed solution was put into a 50mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, and heated in an intelligently temperature-controllable heating furnace. The reaction conditions were: reaction temperature 120°C, reaction time 10 hours. After natural cooling, the hydrothermal product was centrifuged, washed three times with distilled water and absolute ethanol, and then dried in vacuum at 60° C. for 24 hours to obtain a light brown powder.

[0059] Its XRD spectrum is as Figure 4 As shown, the analytical XRD spectrum shows that the prepared sample has a good crystal structure, and the product is basic...

Embodiment 3

[0061] Add 0.0375mmol of potassium permanganate into a beaker containing 44mL of distilled water, and stir under the action of a magnetic stirrer to obtain a purple-red solution; then add 0.3mL of ethylene glycol to the potassium permanganate solution and continue stirring for 5 A mixed solution with a black precipitate can be obtained in 1 hour. The mixed solution was put into a 50mL polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, and heated in an intelligently temperature-controllable heating furnace. The reaction conditions were: reaction temperature 120°C, reaction time 10 hours. After natural cooling, the hydrothermal product was centrifuged, washed three times with distilled water and absolute ethanol, and then dried in vacuum at 60° C. for 24 hours to obtain a light brown powder.

[0062] Its XRD spectrum is as Figure 7 As shown, the analytical XRD spectrum shows that the prepared sample has a good crystal structure, and the product is basi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com