Porous manganese dioxide of nanofibre texture and preparation method thereof

A technology of nanofibers and manganese dioxide, which is applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of irregular product appearance, impure product phase, and reduced material purity, and achieve a simple and easy-to-operate synthesis method and easy Effect of industrialization and rich void structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

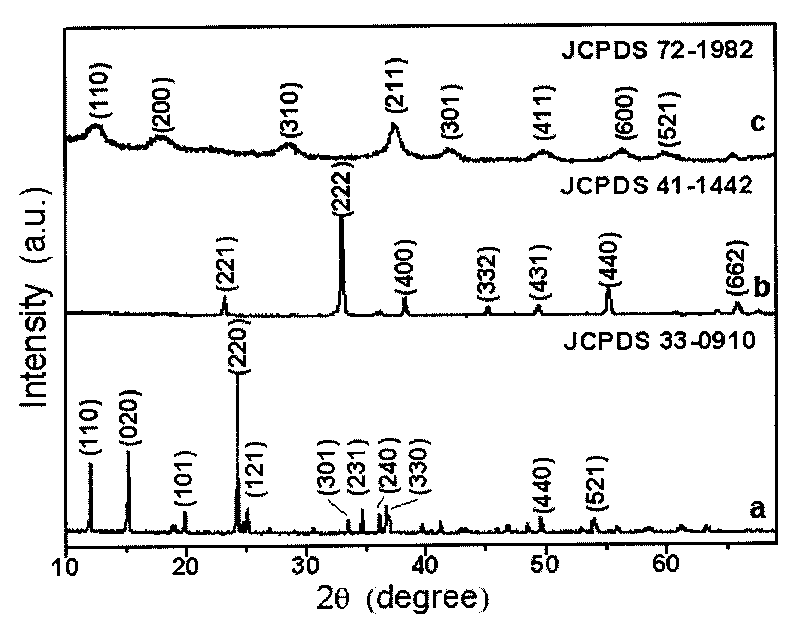

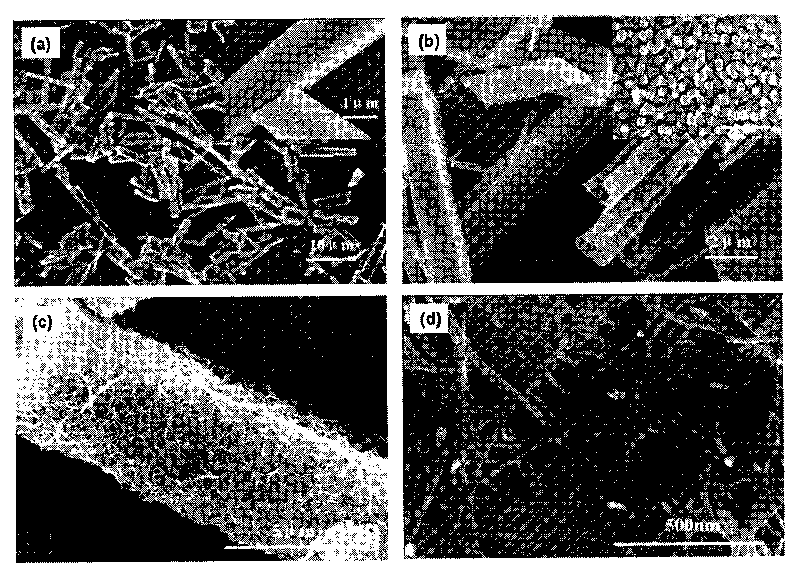

[0021] Dissolve 158g of manganese dichloride tetrahydrate in 4L of water, and dissolve 225g of potassium sodium tartrate tetrahydrate in 4L of water; add potassium sodium tartrate solution to the manganese dichloride solution under magnetic stirring at room temperature, and react for 15 minutes; Then the reaction mixture was transferred to a 10L polytetrafluoroethylene-lined hydrothermal kettle, and hydrothermally reacted at 120°C for 12 hours; cooled to room temperature, the material liquid was taken out for dehydration and washed with distilled water for 5-6 times, and dried at 100°C for 10 hours. A pale pink bar of manganese tartrate was obtained.

[0022] Place the dried manganese tartrate in a muffle furnace at 2°C min -1 The heating rate was programmed to raise the temperature to 600 ° C for calcination, keep the temperature for 4 hours, and slowly cool to room temperature with the furnace temperature to obtain porous manganese trioxide.

[0023] Dissolve 150g of ammoni...

Embodiment 2

[0028] Soluble tartrate salt adopts potassium sodium tartrate tetrahydrate, and soluble manganese salt adopts manganese sulfate monohydrate, according to n(C 4 h 4 o 6 2- ):n(Mn 2+ )=1:1 ratio feeding, potassium sodium tartrate and manganese sulfate consumption are respectively 225g and 135g, and hydrothermal reaction temperature is 140 ℃, and the reaction times 24h, other is implemented as the same method among the embodiment 1.

[0029] The obtained strip-shaped porous manganese dioxide analysis result is similar to that of Example 1.

Embodiment 3

[0031] Soluble tartrate salt adopts potassium sodium tartrate tetrahydrate, and soluble manganese salt adopts manganese acetate tetrahydrate, according to n(C 4 h 4 o 6 2- ):n(Mn 2+ )=1.2: 1 ratio feeding, potassium sodium tartrate and manganese acetate consumption are respectively 271g and 196g, and the hydrothermal reaction temperature is 120 ℃, and the reaction times 8h, other is implemented in the same method as in embodiment 1.

[0032] The obtained strip-shaped porous manganese dioxide analysis result is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com