Patents

Literature

56results about How to "Fresh and mellow taste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing congou black tea from anji white tea

ActiveCN103749755AControl temperature and humidityTransformed properlyPre-extraction tea treatmentFermentationBlack teas

The invention relates to a black tea preparing method and particularly relates to a method for preparing congou black tea from anji white tea. The method sequentially comprises the following steps: picking based on a one-bud and one-leaf standard; withering; rolling; fermenting: arranging the rolled leaves to be fermented into a bamboo basket, controlling the leaf stacking thickness to be 8-10cm, uniformly spreading, and layering the leaves on a fermentation rack; fermenting by using a tea fermenting machine, controlling the air temperature at 35-40 DEG C, keeping the leaf temperature 30-32 DEG C, the relative humidity over 95% and sufficient oxygen supply, recording the fermentation time beginning from the rolling time, and controlling the fermentation time to be 5.5-6.0h. At the later period of fermentation, the temperature of a fermentation chamber is lowered and is controlled at 30-35 DEG C, so that the excessive fermentation is avoided; the moderate fermentation is carried out, and the fermented leaves are removed from the fermentation chamber, subjected to heat radiation, cooled and dried. By using the method, the anji white tea can be prepared into the congou black tea which is dark in luster, compact in strip, sweet and durable in fragrance, red bright in liquor color as well as pure, mild and fresh in taste.

Owner:浙江安吉宋茗白茶有限公司

Ginger congou black tea and preparation method thereof

The invention discloses ginger congou black tea and preparation method thereof. The ginger congou black tea is prepared from the following raw materials in part by weight: 20 parts of fresh tea leaves and 1 part of fresh ginger; and after the raw materials are mixed uniformly in a ratio, the ginger congou black tea is prepared by two times of fermentation according to a making technology of blacktea. The ginger congou black tea produced by combination of the fresh tea leaves and the fresh ginger and two times of artificial fermentation keeps excellent quality of the conventional congou blacktea, and is also rich in natural ginger essence. The production technology is simple and strong in operability; the produced black tea is moderate in price and suitable for industrialized production;and the obtained ginger congou black tea is cool and smooth in mouthfeel, has the flavor of ginger, is natural in taste which is not owned in the conventional tea, and has a definite health-care effect.

Owner:ANHUI QIXIANGYUAN TEA CO LTD

Ecological oolong black tea processing method

InactiveCN103947778ATight and heavyBack to Gan LiqiangPre-extraction tea treatmentBlack teaOOLONG TEA LEAF

The invention relates to an ecological oolong black tea processing method. Half fermented oolong tea and completely fermented black tea are combined. The preparation method comprises the steps of picking up fresh leaves, sunning, cooling, green-making, withering, rolling, fermenting, fixing and pelletizing. The tea prepared by the method has the aroma and taste as good as those of traditional oolong tea, also is fresh and mellow just like black tea and is mellow and normal in aroma and bright in liquor color, and meanwhile, the appearance shape of the traditional oolong black tea leaves is changed; the ecological oolong black tea has the characteristics of coiled shape, tightness and solidness, round particles, and convenient packaging, transportation, storage and brewing of the oolong tea, and also has the characteristics of high production efficiency, good quality and easily achievable product standardization.

Owner:LIANJIANG XUANRENJING TEA IND CO LTD

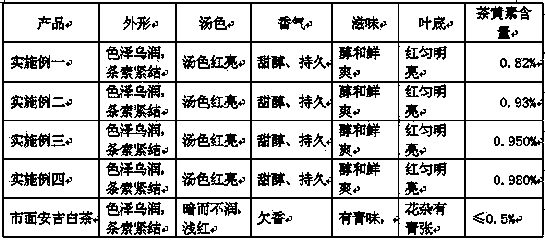

Qimei black tea processing technology

InactiveCN103918817APromotes enzymatic oxidationPromote oxidationPre-extraction tea treatmentBlack teaBitter tastes

The present invention discloses a Qimei black tea processing technology, which comprises raw material selection, withering, rolling, fermentation, shaping, drying, blending matching and other steps. The prepared Qimei black tea has characteristics of slim shape, dark and moisturizing color, and jinhao expose, provides characteristics of red and bright tea soup, enticing aroma emitting, and high and lasting aroma after infusion, and further has characteristics of typical keemun aroma and sweet aroma, fresh and mellow taste, sweet and mellow aftertaste, and red and bright tea residue. In addition, with the processing technology, the defects of bitter taste, thick-black color, boring, no fresh feeling, and low and dull aroma of the previous keemun black tea are overcome, the pursuit of people on the high quality keemun black tea is completely met, and the market prospects are broad.

Owner:ANHUI TIANFANG TEA IND GROUP

Processing technique for black tea

The invention relates to a processing technique for black tea and belongs to the field of production of tea. The processing technique comprises the following steps: firstly, screening the tea; secondly, freezing; thirdly, unfreezing and spreading and drying in the air; fourthly, rolling; fifthly, fermenting; sixthly, carrying out enzyme deactivation; seventhly, primarily baking; eighthly, secondarily baking. According to the processing technique disclosed by the invention, a withering technology is omitted, and a freezing technique and a roller enzyme deactivation process are added; simplicity and convenience in operation are realized, a place is saved, production time is shortened, the productivity is greatly improved, and the technique is easy to grasp and popularize; besides, sufficiency in fermentation is realized; prepared finished black tea has the advantages of compact and even shape and strips, black bloom color and luster, orange red and bright soup, sweet and lasting aroma, faint chestnut-like aroma, mellow taste, freshness, no astringency and obvious sweet after taste; in addition, the content of amino acid reaches 2.20 to 2.84 percent, the content of theoflavin reaches 4.01 to 4.93 percent, the content of thearubigin reaches 13.02 to 16.12 percent and is far higher than that of ordinary black tea; the content of theabrownin is controlled at 3.24 to 3.91 percent, and the content of caffeine is controlled at 1.89 to 2.78 percent; aroma, soup color, taste, mouthfeel and a stomach nourishing effect of the black tea are greatly improved.

Owner:XINYANG AGRI & FORESTRY UNIV

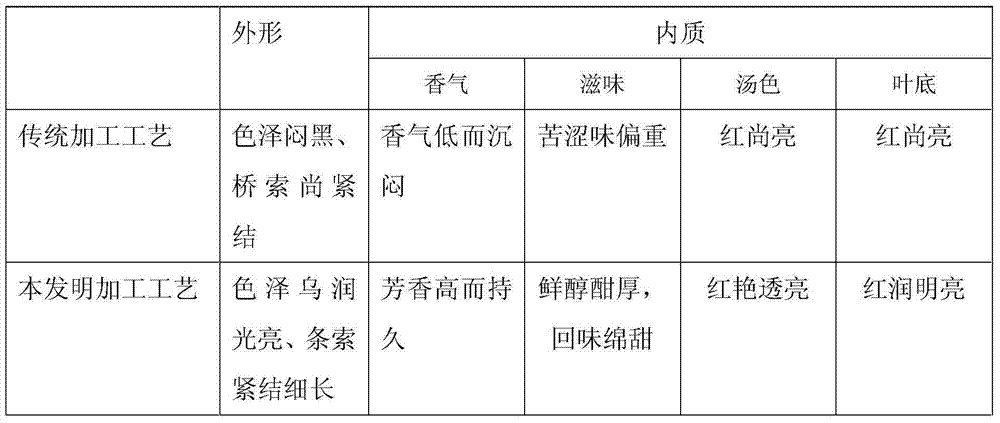

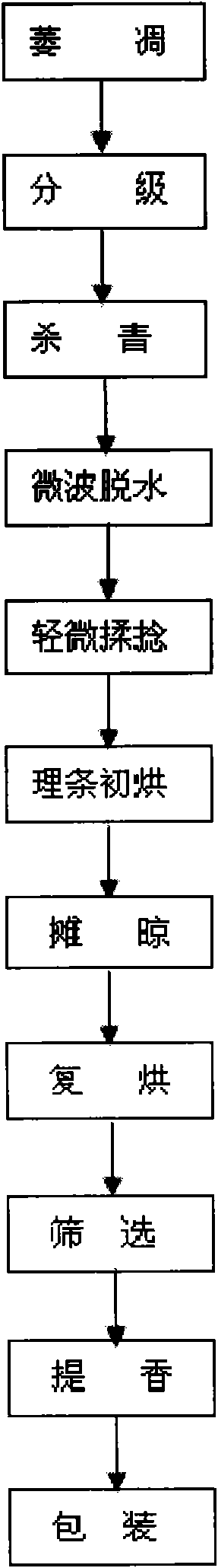

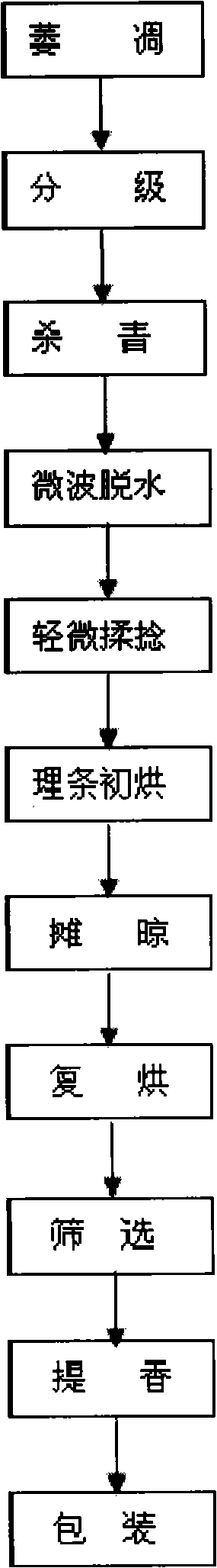

Process flow for preparing Tai Lake jade-green tea

InactiveCN101878824AEmerald green colorFresh and mellow tastePre-extraction tea treatmentLong lastingChemistry

The invention discloses a technical process for preparing Tai Lake jade-green tea, which comprises the steps of withering, grading, enzyme inactivation, microwave dehydration, slight twisting, carding, primary drying, spreading and drying in the air, secondary drying, screening, fragrance improving and the like. The Tai Lake jade-green tea prepared by the process has bamboo leaf-like flat shape, jade-green and oleosus color and luster, a full and fresh taste, pure and long-lasting fragrance, light green and uniform brewed leaves and a unique style. When brewed in a cup, the light green tea leaves expand slowly into bamboo leaf-like shapes to make clear and bright team.

Owner:WUXI DONGTIANXIUZHU TEA

Processing and making method of lotus leaf tea

The invention provides a processing and making method of lotus leaf tea. The method comprises the following nine steps: picking, leaf peeling, green leaf spreading, fixation, air drying, twisting, sieving, flavour extracting and dehydration. The method has the beneficial effects that fresh and tender lotus leaves are picked in proper season and then leaf stalks and coarse veins are peeled, so that pureness of the lotus leaf tea can be maintained; the water steam of the leaf stalks and the coarse veins is adopted for steam fixation, so that the pureness of the aroma of the lotus leaf tea can be further ensured; fixation and air drying are carried out on a conveyor belt, so that the leaf shapes can be maintained and trabes formed by the leaf shapes are uniform; the tea is twisted while the tea is hot, so that the tea can be better shaped and the astringent tastes in lotus leaves are removed, and the astringent tastes can be further covered up after flavour extracting; therefore, the produced lotus leaf tea has orderly appearance, bright green color and pure and thick aroma; the tea soup has dark green and transparent color, tastes fresh, tender and mellow and smells elegant and aromatic; the quality of the lotus leaf tea product is greatly improved.

Owner:高文靓

Steaming-free yellow wine brewing method

InactiveCN1468951AImprove qualityHigh nutritional valueAlcoholic beverage preparationBiotechnologyAcetic acid

The steaming-free yellow wine brewing process uses the materials including rice as main material, yellow wine yeast, yellow wheat yeast, quick yeast, citric acid, glacial acetic acid and water. The technological process includes the following steps: soaking rice in water for 1.5-3 hr and rinsing; fermenting via adding all the materials into one fermenting pot, stirring and fermenting for 15-35 days; squeezing the fermented rice in a plate-frame filter or bag-type filter to separate out rice and obtain yellow wine liquid; and sterilizing and packing the transparent yellow wine in sealed pot.

Owner:陈佩仁

Processing method for dismantling scented tea

InactiveCN101965882APromotes opening and exhalingPromote opennessPre-extraction tea treatmentSINGLE LOBEBoiling point

The invention discloses a processing method for dismantling scented tea. In the method, single-lobe Jasmine flower spell and a tea billet are applied, first-time, second-time and third-time scenting are adopted, second drying operation after every time of scenting is carried out, and then flower frying is carried out after third-time second drying; the flower frying comprises two steps of fourth-time scenting and frying; and when in frying, firstly frying is carried out at the temperature of 85-90 DEG C, a dehumidifying fan is started intermittently in the process of high-temperature frying, then slow frying is carried out at the temperature of 70-80 DEG C, the tea and the flower are rolled and blended and are mixed uniformly, the tea absorbs the scent of the flower fully, and the tea and the flower are removed from heat when the flower is dried, thus a finished product can be obtained. The processing method not only is beneficial for the tea to absorb more fragrant components with low boiling point, but also is beneficial to improving the fragrance freshness degree, simultaneously, is more beneficial to absorbing more concentrated fragrance type fragrant components and increasing concentration and endurance of the fragrance and soaking resistance, and has high drinking value. When in making, the dried flower absorbs water to expand and bloom slowly, and is suspended in a cup, which is vivid and has unique appreciation value.

Owner:SICHUAN WENG TEA IND

Processing and making method of sweet potato leaf tea

The invention relates to a processing and making method of sweet potato leaf tea. The processing and making method is characterized by comprising nine steps as follows: picking, stripping, tedding, fixation, drying with wind, rolling, sieving, aroma-increasing, dehydration and the like. The processing and making method has the beneficial effects that in appropriate seasons, fresh and tender sweet potato leaves are picked, and leaf stems and crude veins are stripped, so that clean and pure degrees of the sweet potato leaf tea can be maintained, and steam of the leaf stems and the crude veins is used for performing steam fixation, and pure fragrance of the sweet potato leaf tea can be further guaranteed; fixation and drying with wind can be performed through a conveyor belt, so that the shape of leaf blades can be maintained, and shapes, appearances and dimensions of the formed tea are uniform; rolling is performed when the dried tea is hot, so that perfect models can be obtained, bitterness in the sweet potato leaves can be removed, and after the aroma increasing, the bitterness can be further covered. The sweet potato leaf tea made in the manner is tidy in appearances, emerald green in color, clean, pure and strong in fragrance, dark green and transparent in color of tea soup, fresh, tender and mellow in taste of the tea soup, and elegant and fragrant in smell of the tea soup. The quality of sweet potato leaf tea products is greatly improved.

Owner:聂洪品

Preparation method of pot-stewed whole chicken

InactiveCN103549471ADeliciousFresh and mellow tasteMulti-step food processesFood preparationMaterials preparationCooked food

The invention provides a preparation method of a pot-stewed whole chicken, which belongs to the technical field of processing of cooked chicken products. The preparation method comprises the steps of preparing pickling powder, washing, pickling, toasting, hot baking, marinating, drying, packaging and sterilizing. The preparation method has the beneficial effects that special formula materials, a special material preparation ratio and a special material preparation method are adopted, and a special toasting and hot-baking technology is adopted, so that the nutrition and the taste are immersed and cured in the chicken; processing steps and processing tempos are unique and ordered and spices and condiments are sufficiently immersed into the chicken, so that the taste of the chicken is the same from the inside to the outside; the chicken is delicious in taste, is tender and mellow and is delicate in meat quality; the whole chicken is gold in color and luster, is crispy and tasty and has long aftertaste; the chicken has the effects of stimulating the appetite and tonifying the spleen; meanwhile, as being cooked properly, the chicken is easy to divide when being eaten and is convenient for eaters to eat outdoors or on trips.

Owner:CHONGQING LUYU LIQIANG FOOD

Production method of Osmanthus Tie Guanyin

ActiveCN101897372AFresh and mellow tastePreserve the charmPre-extraction tea treatmentOsmanthusFood science

The invention discloses a production method of Osmanthus Tie Guanyin, comprising the following steps: selecting and processing tea billets, picking fresh flowers, scenting, spreading during the scenting, performing rocket and roasting. The invention has the advantages of enriching the varieties of the Osmanthus Tie Guanyin product, reserving the aroma of the Tie Guanyin, carrying with intense Osmanthus fragrance, having pure and mild taste and overcoming the defect of slight bitter and astringent taste of the Tie Guanyin.

Owner:FUJIAN EIGHT HORSES TEA

Production method of red koji yellow rice wine

The invention provides a production method of a red koji yellow rice wine which is clear, transparent, unique in flavor and stable in quality. The production method comprises the following steps: by taking water, glutinous rice, red koji and yeast as raw materials, soaking the rice, steaming the rice, putting into a jar and performing saccharification, fermentation, squeezing, preliminary filtration, wine decoction, aging, storage, secondary filtration, sterilization and filling steps to obtain the red koji yellow rice wine. The production method provided by the invention has the beneficial effects that the color of the obtained red koji yellow rice wine is from orange to dark brown, clear and transparent in appearance, has unique fragrance of the yellow rice wine and no extraordinary fragrance, is mellow, fresh and cool in taste and has no peculiar smell, a wine body is coordinated, and the red koji yellow rice wine has the typical style of the yellow rice wine variety, wherein the content of total sugars is 15.1-40.0g / L, the content of non-sugar solids is not less than 18.5%, the alcohol degree is not less than 10.0%, the content of total acids is 3.5-7.5g / L, the content of amino acid-state nitrogen is not less than 0.25g / L, the pH value is 3.5-4.5, the content of calcium oxide is not more than 1.0g / L and the total number of colonies is not more than 50cuf / g.

Owner:FUJIAN LUOYUAN FUSHUANGHONG WINE CO LTD

Preparation method of novel loach and purple yam beverage

ActiveCN104886693AEasy to get ingredientsEasy to prepareFood ingredient functionsFood preparationAdditive ingredientAllium sativum

The invention discloses a preparation method of a novel loach and purple yam beverage and belongs to the field of food beverage preparation. The method includes the following steps: firstly, preparing, by weight, 15-20 parts of live loach, 6-8 parts of fresh purple yams, 2-5 parts of chives, 2-3 parts of garlic, 3-5 parts of sodium chloride and 3-5 parts of green tea; secondly, preparing loach meat paste; thirdly, preparing purple yam juice; fourthly, compositing; fifthly, heating and filtering. The preparation method is simple, raw material ingredients are easily available, processing cost is low, and the prepared loach and purple yam beverage is milky-white and transparent in appearance and fresh and mellow in taste, has healthcare efficacies of tonifying the stomach and widening the intestines, relaxing the bowels and detoxifying, tonifying the liver, spleen and kidney, removing stasis and regulating middle qi and reducing phlegm, and has high marketing value.

Owner:海门市创豪工业设计有限公司

Processing and production method of mulberry-leave tea

InactiveCN105454474AGuaranteed aromaNeat appearancePre-extraction tea treatmentTea substituesFlavorEnzyme

The invention discloses a processing and production method of mulberry-leave tea. The invention is characterized in that the processing and production method comprises the following nine major steps: picking the mulberry leaves, peeling the mulberry leaves, airing the enzymes, deactivating the enzymes, air-drying, kneading, screening and classifying, refining the aroma, dehydrating and the like. The processing and production method has the beneficial effects that the leaf stems and the thick leaf veins of the fresh and tender mulberry leaves which are picked in proper season are peeled, so that the refreshing and pure taste of the mulberry-leave tea can be preserved; enzymes in the leaf stems and the thick leaf veins are further deactivated by water vapor, so that the pure aroma of the mulberry-leave tea can be further ensured; the enzyme deactivation and the air-drying are performed on a conveyer belt so that the shapes of the mulberry leaves are kept and the strips formed by the mulberry leaves are uniform in shape; the kneading is performed when the mulberry leaves are hot, so that the mulberry leaves can be better shaped and the astringent taste of the mulberry leaves is removed; and the astringent taste can be further covered by the step of refining the aroma. The mulberry-leave tea produced according to the processing and production method has the advantages that the mulberry-leave tea is uniform in appearance, jade-green in color, refreshing and thick in aroma, dark-green and transparent in tea-soup color, tender and mellow in tea-soup taste as well as exquisite and fragrant tea-soup flavor. The processing and production method greatly improves quality of the mulberry-leave tea product.

Owner:石爱军

High-aroma Maojian and processing technology thereof

InactiveCN107348027AEfficient volatilizationEffective penetrationPre-extraction tea treatmentCooking & bakingSweetness

The invention provides high-aroma Maojian and a processing technology thereof. The processing technology comprises the following steps of performing spreading for cooling, performing rocking of green tea leaves, performing fixation, performing screening, performing moisture regain, performing rolling, performing baking, performing trimming, performing strip tidying and preparing finished products. The high-aroma Maojian is obtained through the processing technology. The high-aroma Maojian is fine and round in dried tea strips, slightly tippy, high in aroma, rich in flower aroma, clear, fresh, green and bright rather than turbid in tea soup color, mellow, fresh and refreshing in taste, obvious in sweetness after taste, and uniform and consistent in leaf bases, and the sense organ enjoyment of people when the people drink the high-aroma Maojian is greatly improved.

Owner:信阳市农业科学院

Processing and production method of grape-leave tea

InactiveCN105454567AKeep it pureKeep the aromaPre-extraction tea treatmentTea substituesFlavorVitis vinifera

The invention discloses a processing and production method of grape-leave tea. The invention is characterized in that the processing and production method comprises the following nine major steps: picking the grape leaves, peeling the grape leaves, airing the enzymes, deactivating the enzymes, air-drying, kneading, screening and classifying, refining the aroma, dehydrating and the like. The processing and production method has the beneficial effects that the leaf stems and the thick leaf veins of the fresh and tender grape leaves which are picked in proper season are peeled, so that the refreshing and pure taste of the grape-leave tea can be preserved; enzymes in the leaf stems and the thick leaf veins are further deactivated by water vapor, so that the pure aroma of the grape-leave tea can be further ensured; the enzyme deactivation and the air-drying are performed on a conveyer belt so that the shapes of the grape leaves are kept and the strips formed by the grape leaves are uniform in shape; the kneading is performed when the grape leaves are hot, so that the grape leaves can be better shaped and the astringent taste of the grape leaves is removed; and the astringent taste can be further covered by the step of refining the aroma. The grape-leave tea produced according to the processing and production method has the advantages that the grape-leave tea is uniform in appearance, jade-green in color, refreshing and thick in aroma, dark-green and transparent in tea-soup color, tender and mellow in tea-soup taste as well as exquisite and fragrant tea-soup flavor. The processing and production method greatly improves quality of the grape-leave tea product.

Owner:高文靓

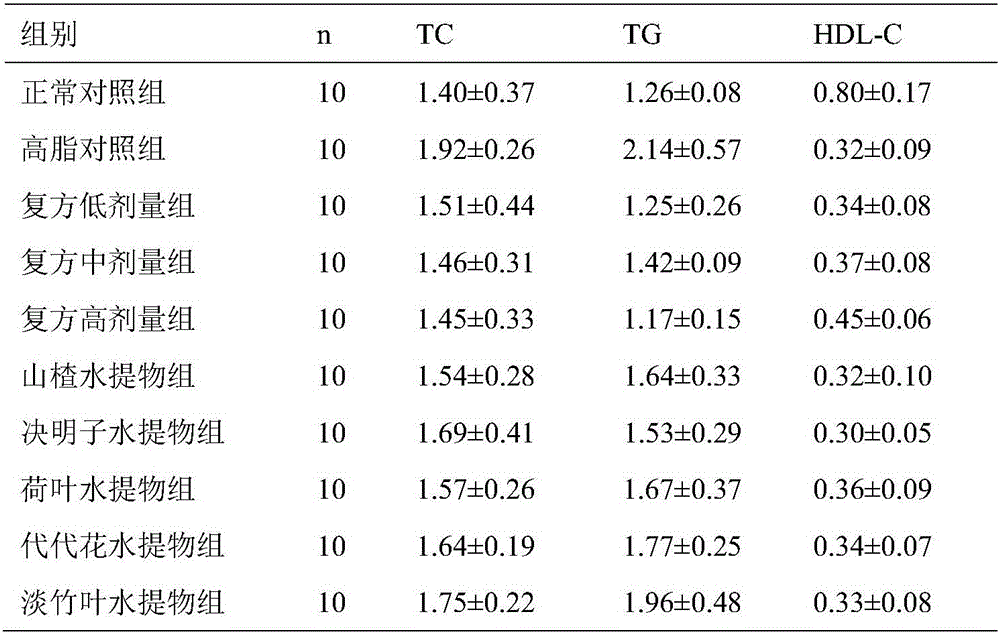

Lipid-lowering composition, and preparation method and use thereof

InactiveCN106729023AThe production process is simpleLipid-lowering ingredients are clearPre-extraction tea treatmentMetabolism disorderBlood lipidsHerb

The invention provides a lipid-lowering composition. The liquid-lowering composition is prepared from the following raw materials in parts by weight: 8 to 12 parts of raw hawthorn fruit, 13 to 17 parts of Chinese yam, 8 to 12 parts of semen cassia, 4 to 8 parts of lotus leaves, 4 to 8 parts of seville orange flowers, 1 to 5 parts of common lophatherum herb, and 1 to 5 parts of prepared liquorice root, The invention also provides lipid-lowering tea which is prepared by adopting oolong as base and adding the composition. The edible and medical herbs are selected and matched according to an assistant and guide matching rule of traditional Chinese medicine, the production process is simple, the lipid-lowering component is definite, the taste is fresh and thick, and tea fragrance is achieved. The product has an efficacy for assisting the lowering of blood lipid. After people eat the lipid-lowering composition for a long time, the blood lipid can be lowered to a normal standard, and the blood lipid balance can be maintained; and all used components are edible and medical herbs, so that the safety is high, and the lipid-lowering tea is suitable for being drunk for a long time.

Owner:FUJIAN UNIV OF TRADITIONAL CHINESE MEDICINE

Delicate fragrance-type Fenghuang-dancong tea and a preparation method and application thereof

ActiveCN104920652AEfficient accumulationPromote formationPre-extraction tea treatmentClimate change adaptationCooking & bakingNitrogen

The present invention relates to the technical field of tea leaf processing, and particularly relates to delicate fragrance-type Fenghuang-dancong tea and a preparation method and application thereof. The preparation method includes: sunlight withering fresh tea leaves of Fenghuang-dancong tea plant varieties, cooling green leaves, making green leaves with technology of rocking green leaves with short time and less times, and followed by nitrogen treating, de-enzyming, twisting and twice baking the tea leaves to obtain delicate fragrance-type Fenghuang-dancong tea. The method is different from the traditional Fenghuang-dancong tea which uses a repeat way of making of green leaves and has 10 hour-long baking time, the delicate fragrance-type Fenghuang-dancong tea is prepared by 3 times of short time rocking of green leaves, long time cooling of green leaves and short time baking, effectively accumulating delicate fragrance-type fragrant substances and promoting the formation of delicate fragrance-type characteristic fragrance. The prepared delicate fragrance-type Fenghuang-dancong tea has the following characteristics: delicate fragrance, fragrance of a flower, mellow, delicious and refreshing taste, sweet aftertaste, tea soup with golden (orange) and bright color, cord and tight knot shape, greenish brown color and luster, even and neat tea-leaf dregs, soft and resistance brewing leaf texture, etc. Compared with the traditional process, the process-cycle of the delicate fragrance-type Fenghuang-dancong tea is simple in operation, short in time consuming and low in cost.

Owner:SOUTH CHINA AGRI UNIV

Processing method of freeze-dried black tea

InactiveCN110122611APreserve nutrientsFull of nutritionPre-extraction tea treatmentTemperature controlAdditive ingredient

The invention discloses a processing method of freeze-dried black tea. According to the processing method, black tea named as Guire No. 2 (or another tea variety with high amino acid content and smaller green taste) is subjected to freeze drying and aroma enhancement treatment during processing; the drying process of the black tea is completed in a vacuum low-temperature environment, so that the original nutritional ingredients of the black tea are maintained, the color of tea leaves is fresh and bright, and the tea leaves are more conspicuous in quality. After being freeze-dried, the tea leaves are subjected to temperature-controlled aroma enhancement treatment, so that the shapes and colors of the tea leaves change little, the tea leaves do not get black, the nutrients are maintained, the green taste of the tea leaves is reduced, the aroma and taste are improved, the rehydration capability of the tea is good, and the tea is easier to make. The invention provides freeze-dried black tea production schemes respectively for three seasons, i.e., spring, summer and autumn; the prepared freeze-dried black tea is big and fleshy, conspicuous in quality, red and bright in soup color, richand lasting in fragrance, pure and mild as well as fresh and brisk in taste, uniformly red and bright in soaked tea dregs, and rich in nutrition.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

Processing and production method of privet-leave tea

The invention discloses a processing and production method of privet-leave tea. The invention is characterized in that the processing and production method comprises the following nine major steps: picking the privet leaves, peeling the privet leaves, airing the enzymes, deactivating the enzymes, air-drying, kneading, screening and classifying, refining the aroma, dehydrating and the like. The processing and production method has the beneficial effects that the leaf stems and the thick leaf veins of the tender privet leaves which are freshly picked are peeled, so that the refreshing and pure taste of the privet-leave tea can be preserved; enzymes in the leaf stems and the thick leaf veins are further deactivated by water vapor, so that the pure aroma of the privet-leave tea can be further ensured; the enzyme deactivation and the air-drying are performed on a conveyer belt so that the shapes of the privet leaves are kept and the strips formed by the privet leaves are uniform in shape; the kneading is performed when the privet leaves are hot, so that the privet leaves can be better shaped and the astringent taste of the privet leaves is removed; and the astringent taste can be further covered by the step of refining the aroma. The privet-leave tea produced according to the processing and production method has the advantages that the privet-leave tea is uniform in appearance, jade-green in color, refreshing and thick in aroma, dark-green and transparent in tea-soup color, tender and mellow in tea-soup taste as well as exquisite and fragrant tea-soup flavor. The processing and production method greatly improves quality of the privet-leave tea product.

Owner:石爱军

Steaming-free yellow wine brewing method

InactiveCN100343379CHigh nutritional valueAvoid strip lossAlcoholic beverage preparationAcetic acidYeast

The steaming-free yellow wine brewing process uses the materials including rice as main material, yellow wine yeast, yellow wheat yeast, quick yeast, citric acid, glacial acetic acid and water. The technological process includes the following steps: soaking rice in water for 1.5-3 hr and rinsing; fermenting via adding all the materials into one fermenting pot, stirring and fermenting for 15-35 days; squeezing the fermented rice in a plate-frame filter or bag-type filter to separate out rice and obtain yellow wine liquid; and sterilizing and packing the transparent yellow wine in sealed pot.

Owner:陈佩仁

Preparation method of fructus forsythiae black tea

The invention discloses a preparation method of fructus forsythiae black tea. The preparation method comprises the following steps: (1) picking of green tea leaves; (2) cooling; (3) rolling; (4) fermenting; (5) baking; (6) gathering with a shallow basket; and (7) packaging of a finished product. The method specifically comprises the following steps: picking complete fructus forsythiae leaves withlength of less than 3 cm in the first and middle ten-day of May, conducting airing at 20-22 DEG C for 8-10 hours, gently kneading the fructus forsythiae leaves for 40 minutes, heavily kneading the fructus forsythiae leaves in a pressure-increased manner for 20 minutes, and repeating kneading twice; carrying out fermenting at a fermentation temperature of 28-30 DEG C for 4-5 hours; conducting baking at a temperature of 100-110 DEG C for 1.5-2.5 hours; and then gathering the finished product with the shallow basket and packaging the finished product. The fructus forsythiae black tea prepared bythe method is fresh and mellow in taste and red and bright in tea soup, tastes fresh, sweet, mellow and non-astringent, and has the health-care effects of helping gastrointestinal digestion, promotingappetite, inducing diuresis, eliminating edema and the like.

Owner:山西省林业和草原科学研究院 +1

Drunk product processing method

The invention relates to a producing method of a kind of food, that is, a producing method of a kind of the ebriety product. The steps of the method are: 1) put the crab or spiral shell, soybean sauce and a little of salt in the container; 2) Pressurize; 3) store it in the refrigerator or under the common temperature for 6-10 days; 4) it can be eaten in raw way or in cooked way. The producing method of The invention discloses particular and easy. Moreover, it has no antiseptic and has abundant nutrition. It tastes good and can protect illness. Especially, it contains the smell of the wine but contains no wine and it has a low cost.

Owner:陈一鸣

Processing and production method of gingko-leave tea

The invention discloses a processing and production method of gingko-leave tea. The invention is characterized in that the processing and production method comprises the following nine major steps: picking the gingko leaves, peeling the gingko leaves, airing the enzymes, deactivating the enzymes, air-drying, kneading, screening and classifying, refining the aroma, dehydrating and the like. The processing and production method has the beneficial effects that the leaf stems and the thick leaf veins of the fresh and tender gingko leaves which are picked in proper season are peeled, so that the refreshing and pure taste of the gingko-leave tea can be preserved; enzymes in the leaf stems and the thick leaf veins are further deactivated by water vapor, so that the pure aroma of the gingko-leave tea can be further ensured; the enzyme deactivation and the air-drying are performed on a conveyer belt so that the shapes of the gingko leaves are kept and the strips formed by the gingko leaves are uniform in shape; the kneading is performed when the gingko leaves are hot, so that the gingko leaves can be better shaped and the astringent taste of the gingko leaves is removed; and the astringent taste can be further covered by the step of refining the aroma. The gingko-leave tea produced according to the processing and production method has the advantages that the gingko-leave tea is uniform in appearance, jade-green in color, refreshing and thick in aroma, dark-green and transparent in tea-soup color, tender and mellow in tea-soup taste as well as exquisite and fragrant tea-soup flavor. The processing and production method greatly improves quality of the gingko-leave tea product.

Owner:高文靓

Processing and making method of persimmon leaf tea

The invention relates to a processing and making method of persimmon leaf tea. The processing and making method is characterized by comprising nine steps as follows: picking, stripping, tedding, fixation, drying with wind, rolling, sieving, aroma-increasing, dehydration and the like. The processing and making method has the beneficial effects that in appropriate seasons, fresh and tender persimmon leaves are picked, and leaf stems and crude veins are stripped, so that clean and pure degrees of the persimmon leaf tea can be maintained, and steam of the leaf stems and the crude veins is used for performing steam fixation, and pure fragrance of the persimmon leaf tea can be further guaranteed; fixation and drying with wind can be performed through a conveyor belt, so that the shape of leaf blades can be maintained, and shapes, appearances and dimensions of the formed tea are uniform; rolling is performed when the dried tea is hot, so that perfect models can be obtained, bitterness in the persimmon leaves can be removed, and after the aroma increasing, the bitterness can be further covered. The persimmon leaf tea made in the manner is tidy in appearances, emerald green in color, clean, pure and strong in fragrance, dark green and transparent in color of tea soup, fresh, tender and mellow in taste of the tea soup, and elegant and fragrant in smell of the tea soup. The quality of persimmon leaf tea products is greatly improved.

Owner:张勇

Chili red-bean cake and preparation method thereof

InactiveCN103932087AFresh and mellow tasteRich in nutrientsFood ingredient functionsFood preparationFlavorSnack foods

The invention discloses a chili red-bean cake and a preparation method thereof. The chili red-bean cake comprises the following raw materials in parts by mass: 400-430 parts of fresh chili, 155-175 parts of Chinese dates, 1050-1100 parts of red beans, 490-530 parts of soft sugar or xylitol, 150-170 parts of water, 5-10 parts of salt and 1-10 parts of flavoring essence. The preparation method comprises the following steps: removing seeds and stems of the fresh chili, and mixing the fresh chili, the red beans and the Chinese dates in a specific ratio to obtain the chili red-bean cake with nice appearance, bright and attractive color, sweet, refresh, rich and smooth taste and rich nutritional components of chili. According to the chili red-bean cake, chili is adopted for the first time as a main raw material to prepare snack foods, and the application field of chili is broadened. The chili red-bean cake does not contain any preservative, can be stored for a long time at normal temperature, has the advantages of edible safety and wide practicality when serving as chili deep processing products, and has high additional value and industrial value.

Owner:DALIAN NATIONALITIES UNIVERSITY

Chilli red bean cake and preparation method thereof

InactiveCN103932087BReduce spicinessReduce quality impactFood ingredient functionsPreservativeRed bean

The invention discloses a chili red bean cake and a preparation method thereof. The chili red bean cake includes the following raw materials in parts by mass: 400-430 parts of fresh pepper, 155-175 parts of red dates, 1050-1100 parts of red beans, 490-530 parts of soft white sugar or xylitol, 150-170 parts of water, 5-5 parts of salt 10 parts, 1-10 parts of edible spices. The present invention adopts fresh peppers with seeds and tendons removed, and mixes red beans and red dates in a specific proportion to obtain a red bean cake with beautiful appearance, bright and attractive color, sweet and refreshing taste, mellow and delicate, and rich in various nutritional components of peppers. . The invention is the first time that the leisure food is prepared with the pepper as the main raw material, which broadens the application field of the pepper. The product of the invention does not add any preservative, and can be stored at normal temperature for a long time. As a deep-processed product of pepper, the product of the invention is safe to eat, has wide practicability, and has high added value and industrial value.

Owner:DALIAN NATIONALITIES UNIVERSITY

Chicken-flavor health-care shelled melon seed and manufacturing method thereof

InactiveCN103504380AFresh and mellow tasteLower blood sugarNatural extract food ingredientsFood preparationBiotechnologyChicken Flavor

The invention discloses a chicken-flavor health-care shelled melon seed and a manufacturing method of the chicken-flavor health-care shelled melon seed. The chicken-flavor health-care shelled melon seed is prepared from the following raw materials by weight: 120-150 parts of shelled sunflower seed, 10-15 parts of chicken flavor powder, 1-2 parts of loofah sponge, 2-3 parts of bamboo leaf, 2-3 parts of radix paeoniae alba, 2-3 parts of cacumen biotae, 2-3 parts of fried jujube kernel, 2-3 parts of radix puerariae, 1-2 parts of salix leaf, 5-10 parts of konjak flour, 2-3 parts of bleeding-heart glorybower, 5-8 parts of ginger, 5-10 parts of white vinegar, 2-3 parts of scallion stalk powder, and a proper quantity of seasoning liquid and water. Based on the traditional shelled melon seed flavor, the chicken-flavor health-care shelled melon seed has the strong chicken flavor, so that the chicken-flavor health-care shelled melon seed has a special flavor, and is delicious and mellow in taste. At the same time, cacumen biotae contained in the formula has the effect of cooling blood and promoting the circulation of Qi; konjak contained in the formula has the effects of reducing blood sugar, blood pressure, blood fat and so on; with the health-care function of the shelled sunflower seed, the chicken-flavor health-care shelled melon seed can enable a user to enjoy daintiness and avoid the harm of hypertension, hyperlipemia and hyperglycemia.

Owner:HEFEI ZHENTAI LAOYEYE FOOD

Method for preparing health tea by using sweet potato

The invention relates to a method for preparing health tea by using sweet potatoes, which comprises the steps of picking, stripping leaves, sunning, fixing, wind drying, rolling, spraying, setting andimproving incense and dehydrating. The health tea prepared by the method provided by the invention has the advantages of tidy appearance, tight and uniform strands, green color, rich and pure aroma,good quality, clear and green tea color, clear and tender tea flavor, elegant and fragrant tea smell, fragrance, without losing the original tea flavor, easiness in drink, good boiling resistance andbalanced nutrition; the health tea has better health effect on a human body when being brewed for drinking, is refreshing and capable of stopping thirst after being drunk, has remarkable sweet after taste, is capable of clearing liver and improving vision, relaxing bowels and inducing diuresis; after being drunk for a long term, the tea also has effects of enhancing immunity, delaying senescence,clearing away the lung-heat, reducing phlegm, lubricating intestines, reducing blood press, decreasing blood sugar, preventing dyspepsia and other health effects, and greatly improves the quality of sweet potato leaf tea products.

Owner:GUANGXI JIPENG INVESTMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com