Processing method of chestnut-flavor green tea

A processing method and technology of green tea, applied in the direction of tea treatment before extraction, etc., can solve the problems of low degree of mechanization, inability to effectively ensure the quality of chestnut-flavored green tea, style characteristics of chestnut-flavored green tea, and low yield, and achieve enhanced Fully transform and aggregate, improve the aroma concentration and persistence of finished tea, and have the effect of emerald green and oily color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

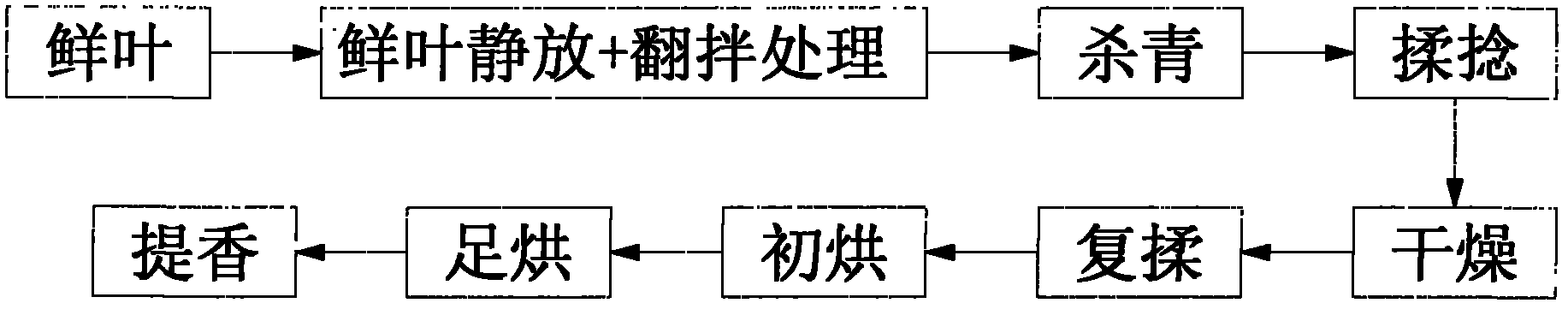

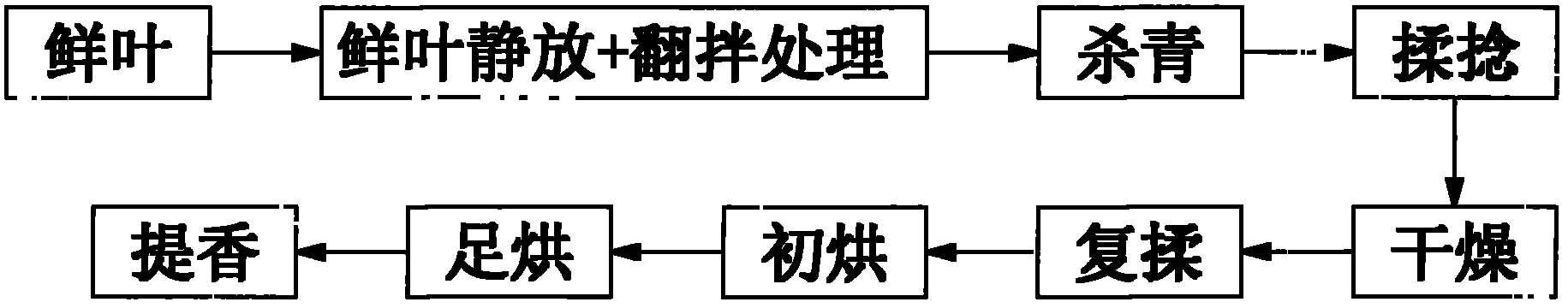

[0017] Embodiment 1: see figure 1 , a method for processing chestnut-flavored green tea leaves, the processing process is as follows,

[0018] a. Fresh leaves: Fresh leaves are collected from fine tea trees such as Fuding Dabaicha, Mingxuan 131, and Fuxuan No. 9 from mid-March to late September. The standard for fresh leaves is one bud and one leaf and one bud and two or three leaves.

[0019] b. Fresh leaves resting + stirring treatment: fresh leaves are placed in the airing room, the area of the airing room is 200 square meters, and the thickness of the airing room is 5cm to 10cm. Moderate dehydration can increase the activity of various hydrolytic enzymes and oxidases in fresh leaves, promote the full transformation of the contents, and is beneficial to the formation of water-soluble sugars and amino acids in tea making, the transformation of some aromatic oils, and the degradation of fat-soluble pigments. Leaf alcohol and leaves and other quality improvements. The ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com