Van body type oil cylinder seat of filter press

A technology of oil cylinder seat and filter press, which is applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc. It can solve the problems of affecting filtration efficiency, short service life, and fatigue resistance, so as to improve filtration efficiency and reduce production costs , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

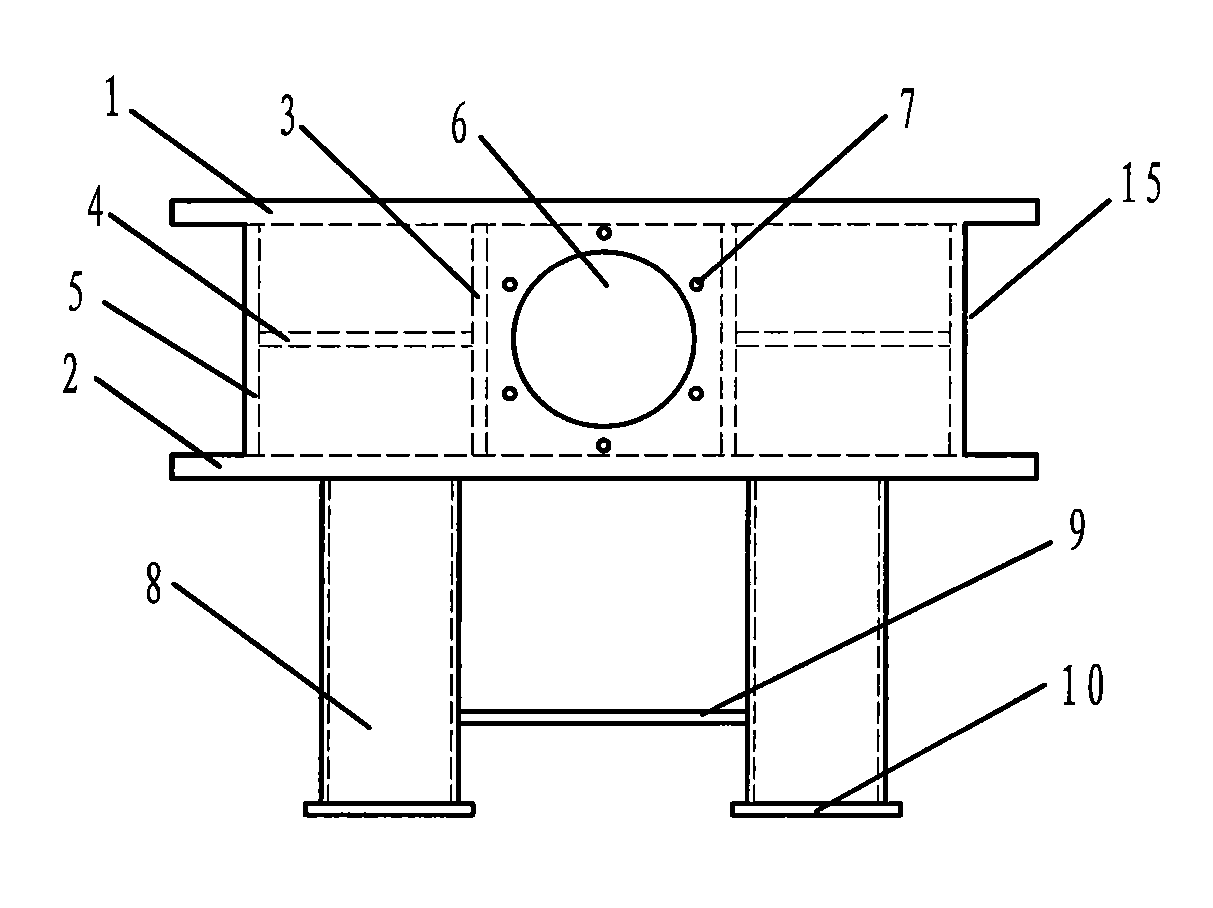

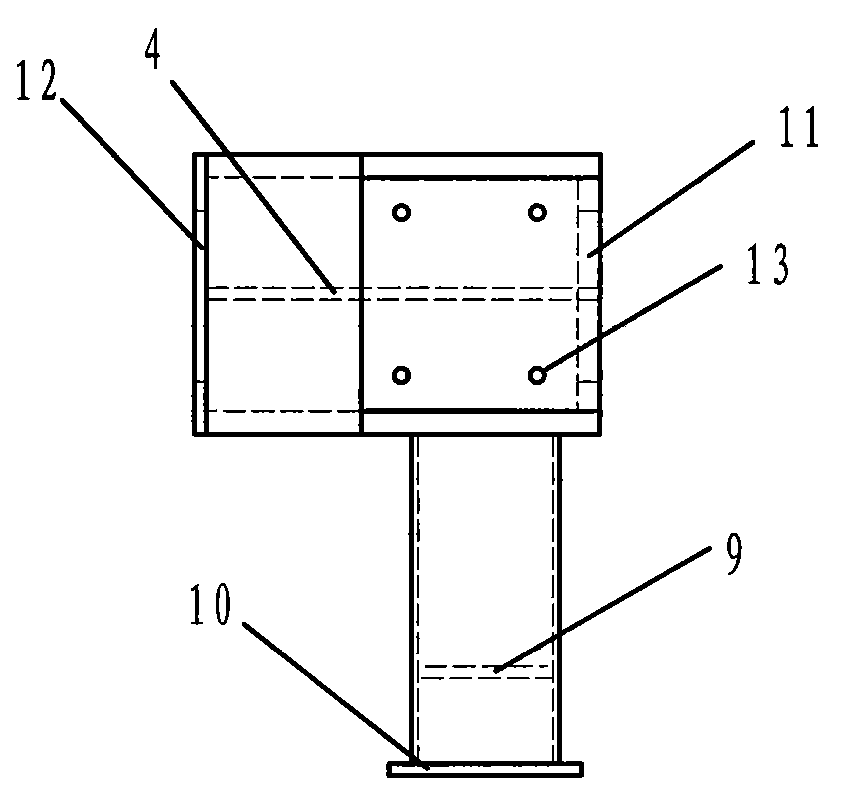

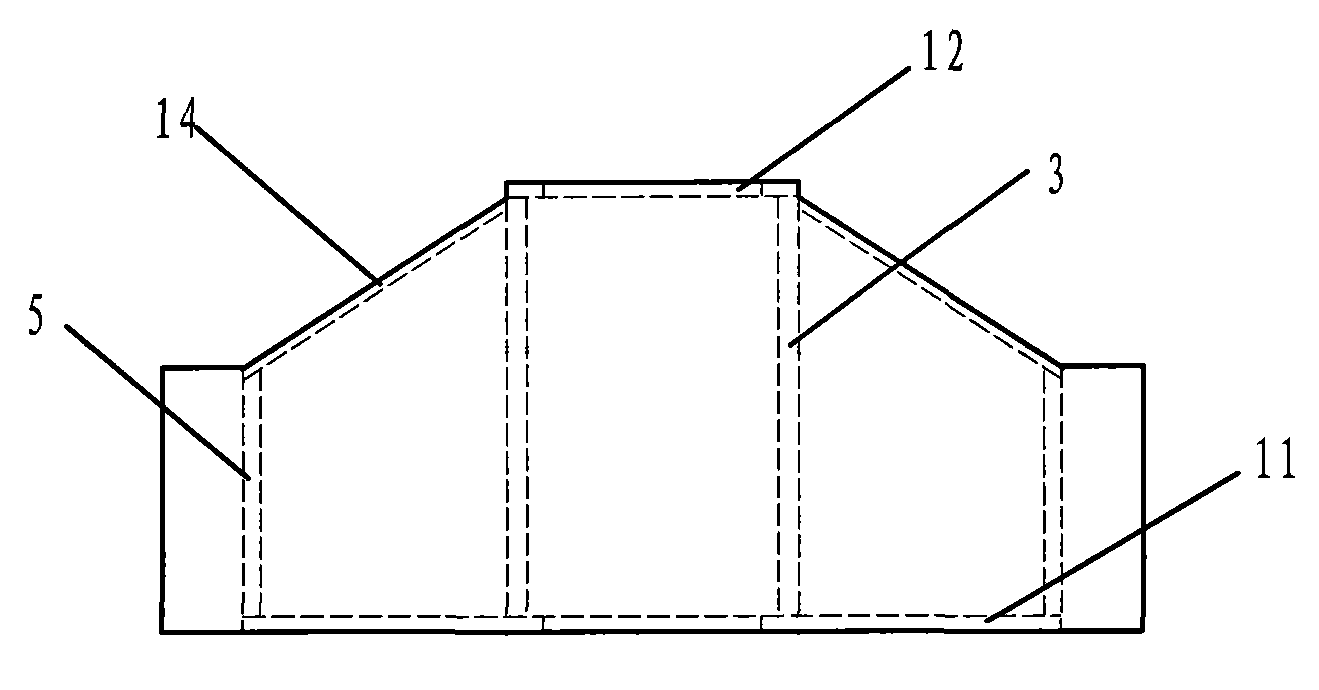

[0014] See figure 1 , figure 2 with image 3 As shown, in the filter press chamber cylinder seat provided by the present invention, a shaping fixture is first made before the structure is welded, and the welded parts are fixed in the fixture. The materials used in the chamber cylinder seat are all carbon structural steel, welded parts When gas cutting, all welding grooves should be punched out. The upper main board 1 is first put into the fixture, the vertical ribs 3 and baffle 5 are welded to the upper main board 1, and then the horizontal ribs 4 and vertical ribs 3 are welded. Connect to the baffle 5, weld the baffle 5 to form the main beam groove 15, and then weld the lower main board 2 to form the main body, and then weld the front panel 11 to the front of the main body according to the groove. The welding inside is welded from the back port, and then the rear panel is welded 12 At the rear end of the main body, the closing plate 14 is finally welded to form a box-type cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com