Carbon fiber/PET composite material as well as preparation method and application thereof

A composite material and carbon fiber technology, applied in the direction of additive processing, etc., can solve the problems of low mechanical strength, poor processability, and excessive fluidity of the parts, and achieve the effects of smooth surface, reduced addition, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

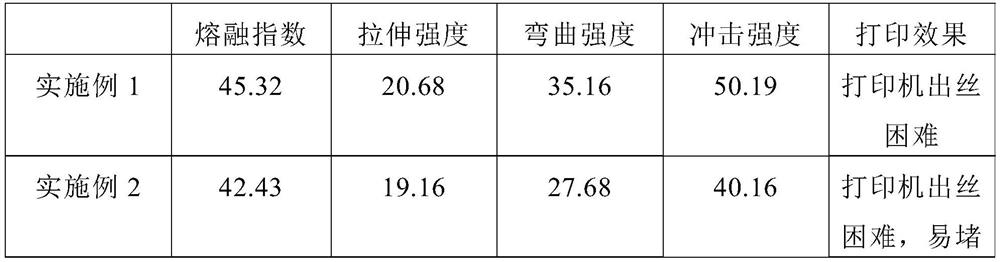

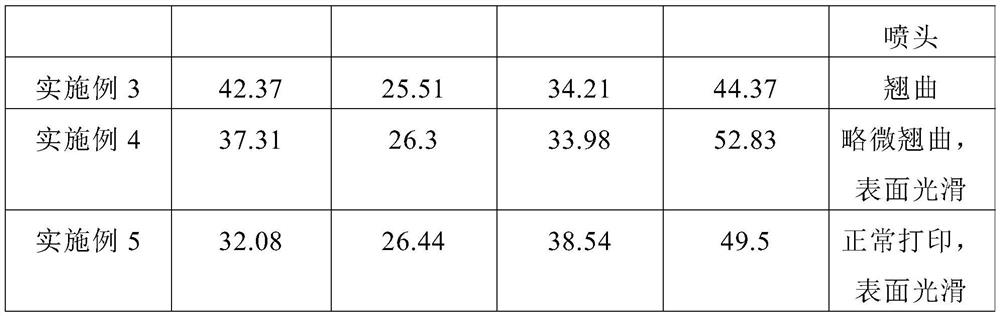

Examples

Embodiment 1

[0038] This embodiment provides a carbon fiber / PET composite material for FDM printing, comprising the following components by weight:

[0039] 80 parts of PET, 20 parts of PBT, 7 parts of compatibilizer (AX8900), 20 parts of toughening agent A (EBA) The preparation method of the carbon fiber / PET composite material for FDM printing in this embodiment includes the following steps:

[0040] Vacuum dry PET, PBT, compatibilizer and toughener respectively;

[0041] The mixture is mixed and extruded by twin-screw, and pelletized on a pelletizer to obtain modified pellets. The temperature of each section of the twin-screw extruder is set in turn: 170°C in the first zone, 180°C in the second zone, and 200°C in the third zone. The fourth zone is 245°C, the fifth zone is 245°C, the sixth zone is 245°C, the seventh zone is 250°C, the eighth zone is 250°C, the ninth zone is 250°C, the machine head is 240°C, the main engine speed is 300r / min, and the feeding frequency is 15r / min;

[0042]...

Embodiment 2

[0044] This embodiment provides a carbon fiber / PET composite material for FDM printing, comprising the following components by weight:

[0045] 70 parts of PET, 30 parts of PBT, 10 parts of compatibilizer (AX8900), 15 parts of toughening agent B (EMA)

[0046] The preparation method of the carbon fiber / PET composite material for FDM printing in this embodiment comprises the following steps:

[0047] Vacuum dry PET, PBT, compatibilizer and toughener respectively;

[0048] The mixture is mixed and extruded by twin-screw, and pelletized on a pelletizer to obtain modified pellet H3. The temperature of each section of the screw extruder is set in turn: 170°C in the first zone, 180°C in the second zone, 200°C in the third zone, The fourth zone is 240°C, the fifth zone is 240°C, the sixth zone is 245°C, the seventh zone is 250°C, the eighth zone is 250°C, the ninth zone is 250°C, the machine head is 240°C, the main engine speed is 300r / min, and the feeding frequency is 15r / min;

[...

Embodiment 3

[0051] This embodiment provides a carbon fiber / PET composite material for FDM printing, comprising the following components by weight:

[0052] 80 parts of PET, 20 parts of PBT, 4 parts of compatibilizer (AX8900), 15 parts of toughening agent A (EBA), 0.5 parts of nucleating agent A (talc powder)

[0053] The preparation method of the carbon fiber / PET composite material for FDM printing in this embodiment comprises the following steps:

[0054] Vacuum dry PET, PBT, chopped carbon fiber, compatibilizer, toughening agent and nucleating agent respectively;

[0055] The toughening agent, compatibilizer and nucleating agent are weighed according to the formula, and mixed at high speed in a high-speed mixer, and the heat generated by the high-speed mixing process is used to coat the nucleating agent on the compatibilizer to obtain a mixed masterbatch H1;

[0056] Mix the mixed masterbatch H1 in step B with PET and PBT after weighing to obtain the mixture H2;

[0057] The mixture H2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com