A steel pipe pile device with outrigger

A technology of steel pipe piles and outriggers, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of difficulty in increasing pile end resistance, difficulty in forming enlarged heads, and poor stability of pile bodies, etc., to achieve increased contact The effect of area, uniform force and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

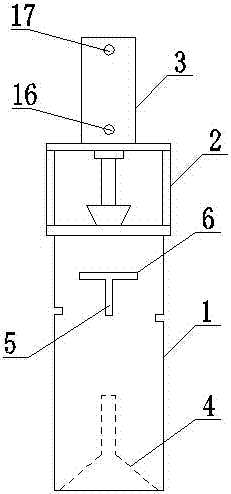

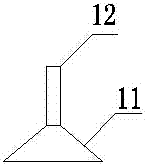

[0027] Such as figure 1 As shown, a steel pipe pile device with outriggers includes a steel pipe pile body 1, a drawing device 2, a hydraulic device 3, an extrusion cone 4 and several groups of outriggers 5; the steel pipe pile body 1 is connected to the bottom of the drawing device 2, and the top of the drawing device 2 is connected to the hydraulic device 3; the bottom of the steel pipe pile body 1 is provided with an extruding cone 4, and the extruding cone 4 is connected to the drawing device through a steel wire rope. The pulling device 2 is connected; the side wall of the steel pipe pile body 1 is provided with several groups of through holes 6, the number of the through holes 6 is the same as that of the outrigger 5, and the size of the through hole 6 is the same as that of the outrigger 5. The dimensions coincide with each other, and an outrigger 5 is arranged in the through hole 6 .

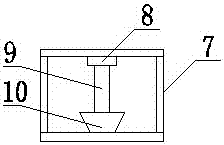

[0028] Such as figure 2 As shown, the drawing device 2 includes a fixed frame 7, ...

Embodiment 2

[0033] A steel pipe pile device with an outrigger, comprising a steel pipe pile body 1, a drawing device 2, a hydraulic device 3, an extruding cone 4 and several sets of outrigger arms 5; the top of the steel pipe pile body 1 It is connected to the bottom of the drawing device 2, and the top of the drawing device 2 is connected to the hydraulic device 3; the bottom of the steel pipe pile body 1 is provided with an extruding cone 4, and the extruding cone 4 is connected to the drawing device 2 through a steel wire rope. connected; the side wall of the steel pipe pile body 1 is provided with several groups of through holes 6, the number of the through holes 6 is the same as that of the outrigger 5, and the size of the through holes 6 is the same as that of the outrigger 5 Matching, the outrigger 5 is arranged in the through hole 6 .

[0034] The drawing device 2 includes a fixed frame 7, an adapter 8, a dowel bar 9 and a wire rope clamp 10, the bottom of the fixed frame 7 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com