Reinforcing steel bar bending structure, reinforcing steel bar bending device and reinforcing steel bar bending method

A technology for bending and reinforcing steel bars, applied in the field of construction equipment, can solve the problems of time-consuming and laborious, the two ends of the steel bars are warped, the reinforcement process, and the complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

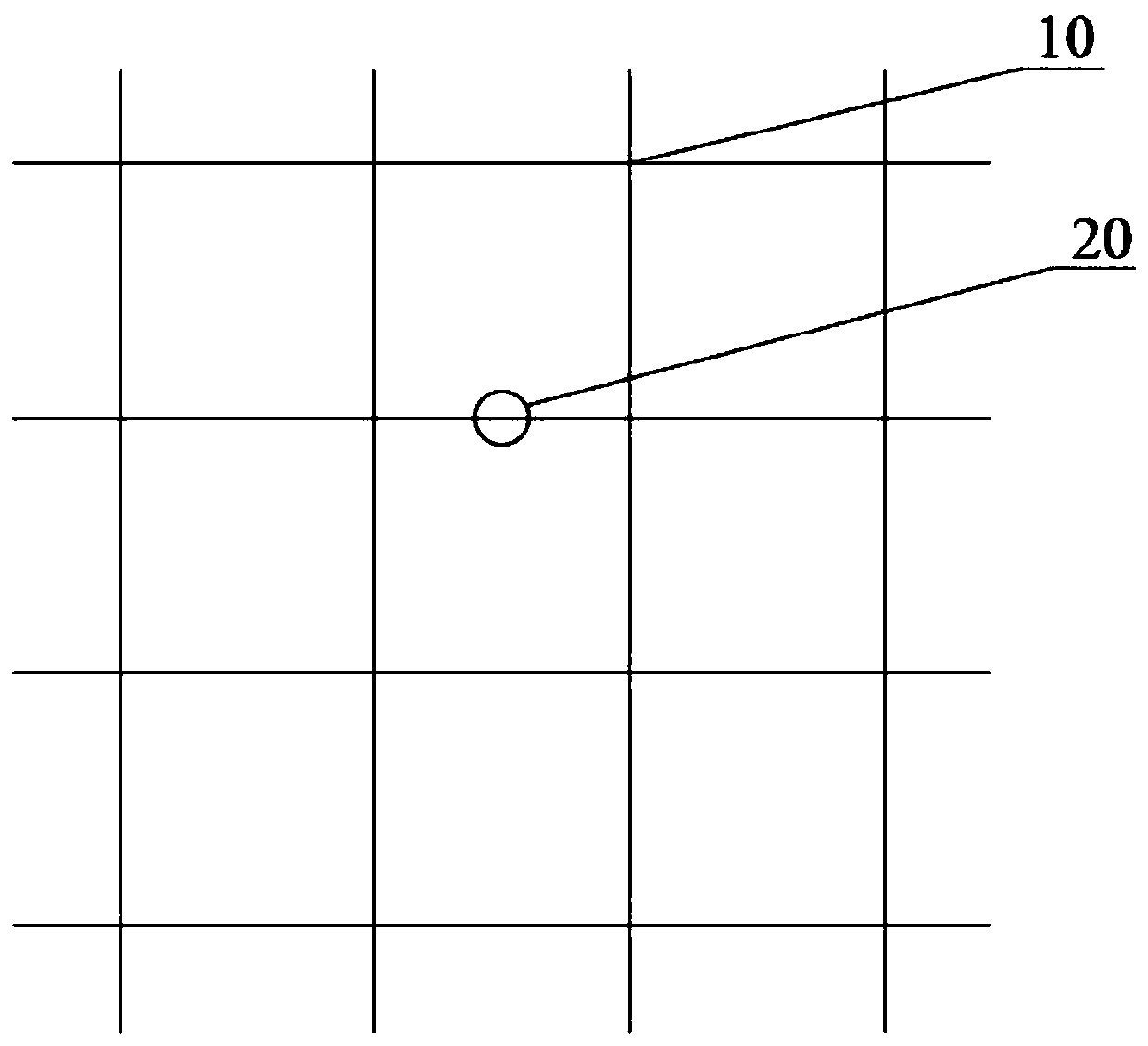

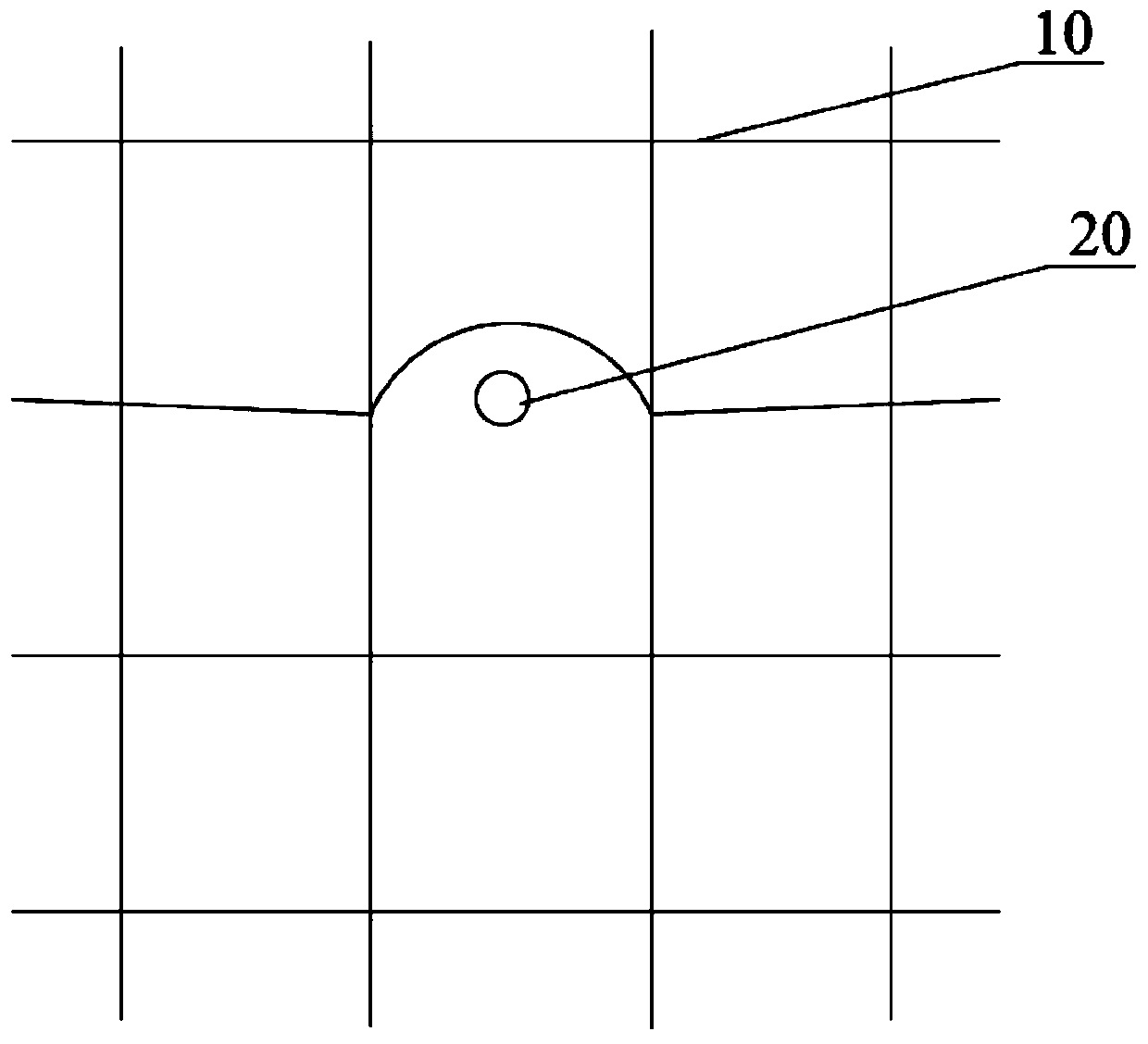

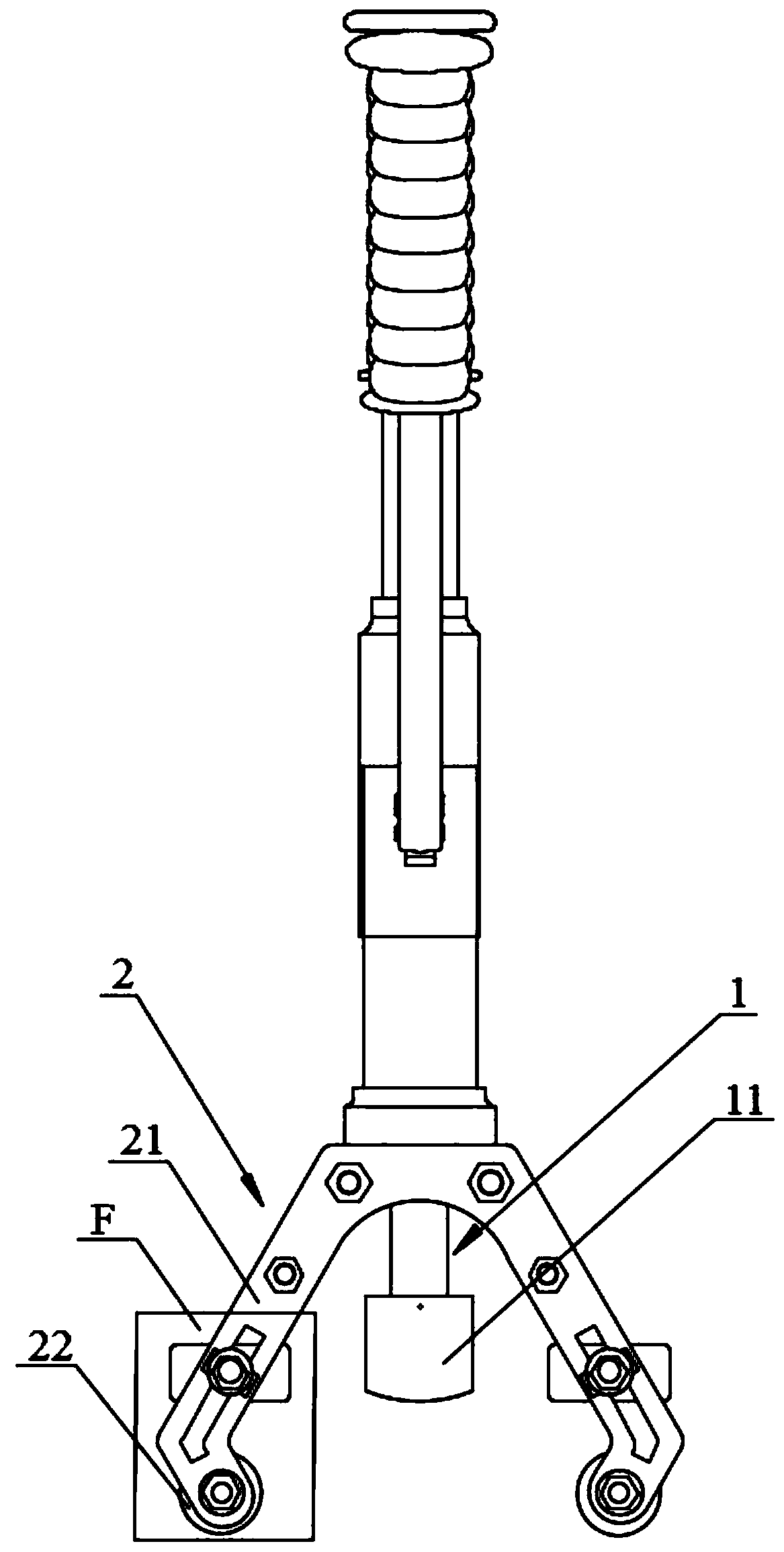

[0040] Such as Figure 3 to Figure 7 As shown, a steel bending structure includes a push rod 1 and a support frame 2. The support frame 2 includes two fixed arms 21, and the push rod 1 passes through the support frame 2 and is located between the two fixed arms 21;

[0041] A pulley 22 is provided at the end of the fixed arm 21, and a pressing block 23 is also provided on the fixed arm 21 corresponding to the pulley 22. A steel bar passing hole is reserved between the pulley 22 and the pressing block 23. Preferably, the pressing block is a square block, and the pulley is a grooved round pulley, which is beneficial to increase the force-bearing area at both ends of the steel bar and further improve the bending quality of the steel bar.

[0042] After pressing the steel bar on the bending structure of the steel bar, push the push rod to make the push rod act in the middle of the steel bar. Since the two ends of the steel bar are pressed by the pressure block, the two ends of the stee...

Embodiment 2

[0049] A steel bar bender includes the steel bar bending structure of Embodiment 1. The steel bar bender also includes a piston rod, an air cylinder, and an air intake pump. One end of the piston rod is connected to the push rod, and the other end is connected to the air cylinder through a spring. The air hole, the air inlet pump is connected with the air hole through the air pipe.

[0050] When used, it is basically the same as that of Embodiment 1, except that the push rod of this embodiment is pushed out by air pressure.

Embodiment 3

[0052] The structure of the third embodiment is basically the same as that of the second embodiment. The difference is that this embodiment replaces the intake pump in the second embodiment with a hydraulic pump. The piston rod and the hydraulic pump are both set in the cylinder, and one end of the piston rod is connected with the push rod. The other end is connected with the hydraulic pump, and the hydraulic pump is connected with the motor. In this embodiment, the push rod is pushed out hydraulically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com