Vacuum glass and processing method thereof

A technology of vacuum glass and processing method, applied in glass forming, glass re-forming, glass manufacturing equipment and other directions, can solve the problems of limited vacuum chamber volume, damage of support points, influence of support points, etc., to reduce production costs, use The effect of long life and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

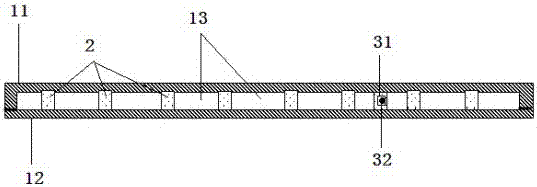

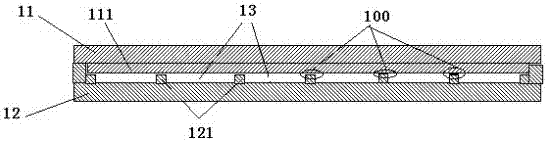

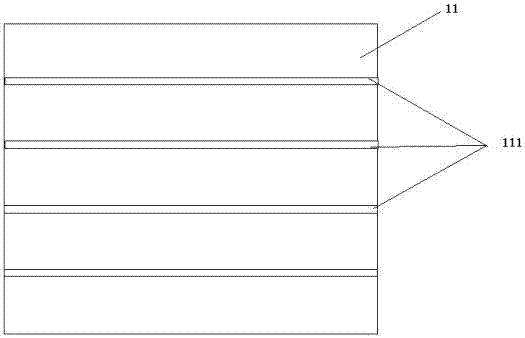

[0056] see Figure 2-4 , which is a structural schematic diagram of a vacuum glass in the embodiment. As shown in the figure: it includes two flat glass 11, 12 arranged in parallel, there is a gap for vacuuming between the two flat glass 11, 12; the edges of the two flat glass 11, 12 are sealed by high temperature melting. In Embodiment 1, the flat glass is preferably high borosilicate glass, and soda lime glass may also be selected. The inner surface of each plate glass 11, 12 has several supporting bars 111, 121 protruding from the inner surface of the plate glass; , 121 are staggered and stacked to form several support surfaces 100; a vacuum gap 13 is formed between the support bars 111, 121 on the inner surface of each plate glass, and the vacuum gap 13 between the two plate glasses communicates with each other. That is to say, the vacuum gap 13 between the support bars 111 of the upper plate glass 11 and the vacuum gap 13 between the support bars 121 of the lower plate ...

Embodiment 2

[0072] Its structure is basically similar to that of Embodiment 1, except that the support bars 111 and 121 are preferably arc-shaped with equidistant or unequal intervals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com